Cutter for chamfering

A technology of milling cutters and milling devices, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of shortened service life of milling cutters, increased cutting load, and difficulty in working, so as to achieve simple milling work, reduce cutting load, and improve The effect of processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

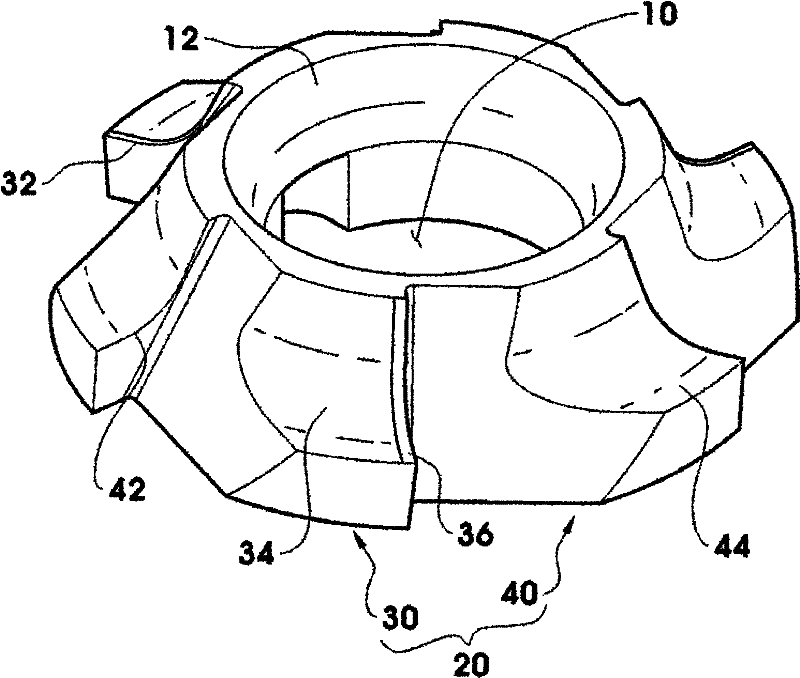

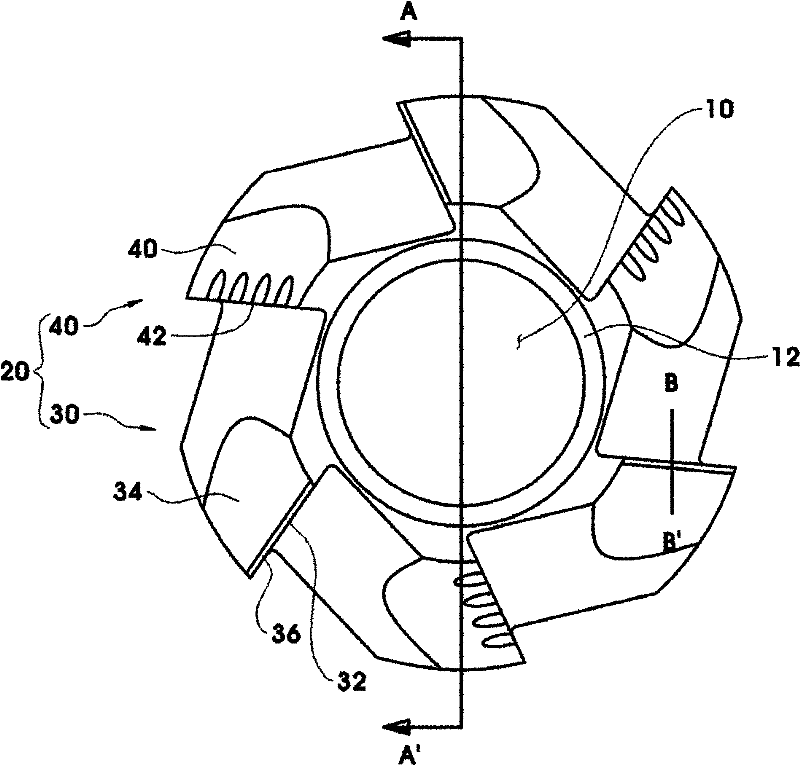

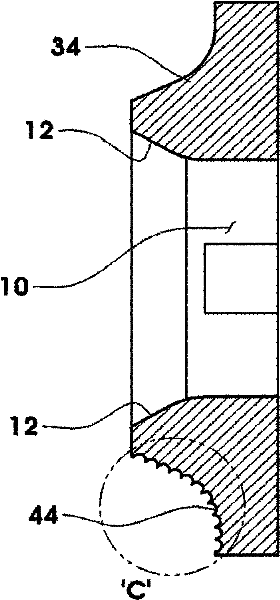

[0022] figure 1 is an oblique view of a milling tool according to an embodiment of the present invention, figure 2 for figure 1 Front view of the milling tool shown, image 3 for figure 2 Sectional view of the milling tool shown on the cutting line A-A’, Figure 4 for figure 2 Rear view of the milling tool shown.

[0023] Such as figure 1 with 2 As shown, the milling tool of the present invention is provided with a through hole 10 in the center, so that the connecting bolt penetrates and connects to the rotating shaft, and forms a gear shape in which a plurality of cutting inserts 20 are radially provided around the through hole 10 . At this time, the number of cutting inserts 20 may be 4 to 8, and is 6 in this embodiment.

[0024] Such as figure 1 with 3 As shown, each cutting insert 20 has a shape that protrudes toward the center as a whole.

[0025] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com