Overlapping high-frequency fine screen

A high-frequency fine sieve, lamination technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of difficult to achieve large-scale equipment, difficult to meet large-scale production, installation, high cost of use, etc., and achieve a compact structure. , The effect of reducing manufacturing costs, saving floor space and occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

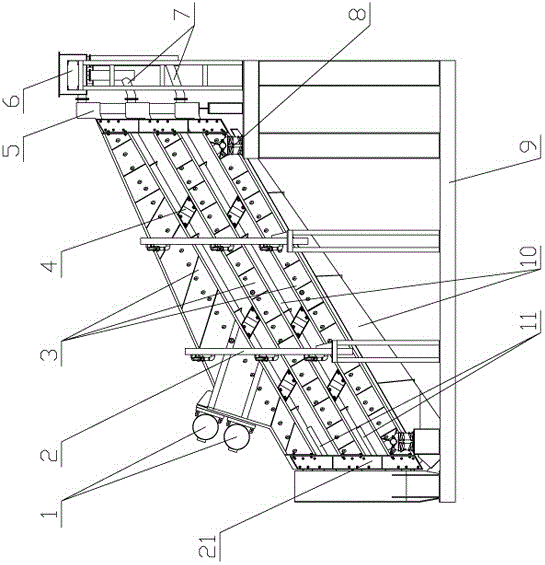

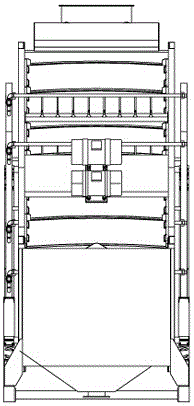

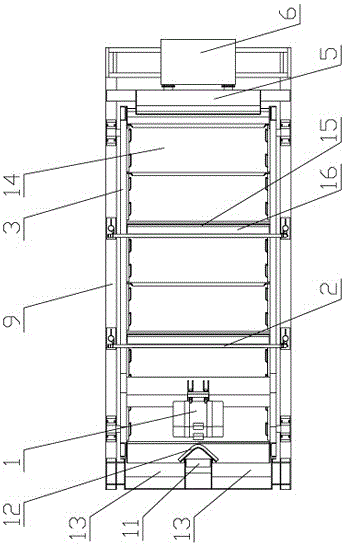

[0026] see Figure 1-Figure 4 , the present invention is a laminated high-frequency fine screen, which has a frame 9, on which several screen units inclined are arranged from top to bottom, and each screen unit includes a screen frame 3, a screen surface 14. Undersieve material receiving hopper 10, oversieve material discharge plate 13 and undersieve material outlet 11, all oversieve material discharge plates guide the oversieve material to the oversieve material general outlet 18 at the bottom of the frame, all undersieve materials The material outlet guides the undersized material to the undersized material outlet 17 at the bottom of the frame. The two ends of the above screening unit are connected together by the end connector 21, and the upper and lower screening units are connected to each other by the intermediate connector 4. Together, one end of the upper part of each screening unit is provided with a distributor 5, and each distributor is connected to a distributor 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com