Single working end swing type automatic electrode grinder for resistance spot welding

A technology of resistance spot welding and working end, which is applied in the direction of resistance welding equipment, electrode maintenance, electrode characteristics, etc., can solve the problem of electrode material uniformity and conductivity on the electrode surface, as well as edge damage, it is difficult to effectively control the excessive cutting of electrode materials, not It has the function of automatic angle compensation step by step to achieve the effect of improving effective power feeding capacity, reducing electrode consumption and reducing cutting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

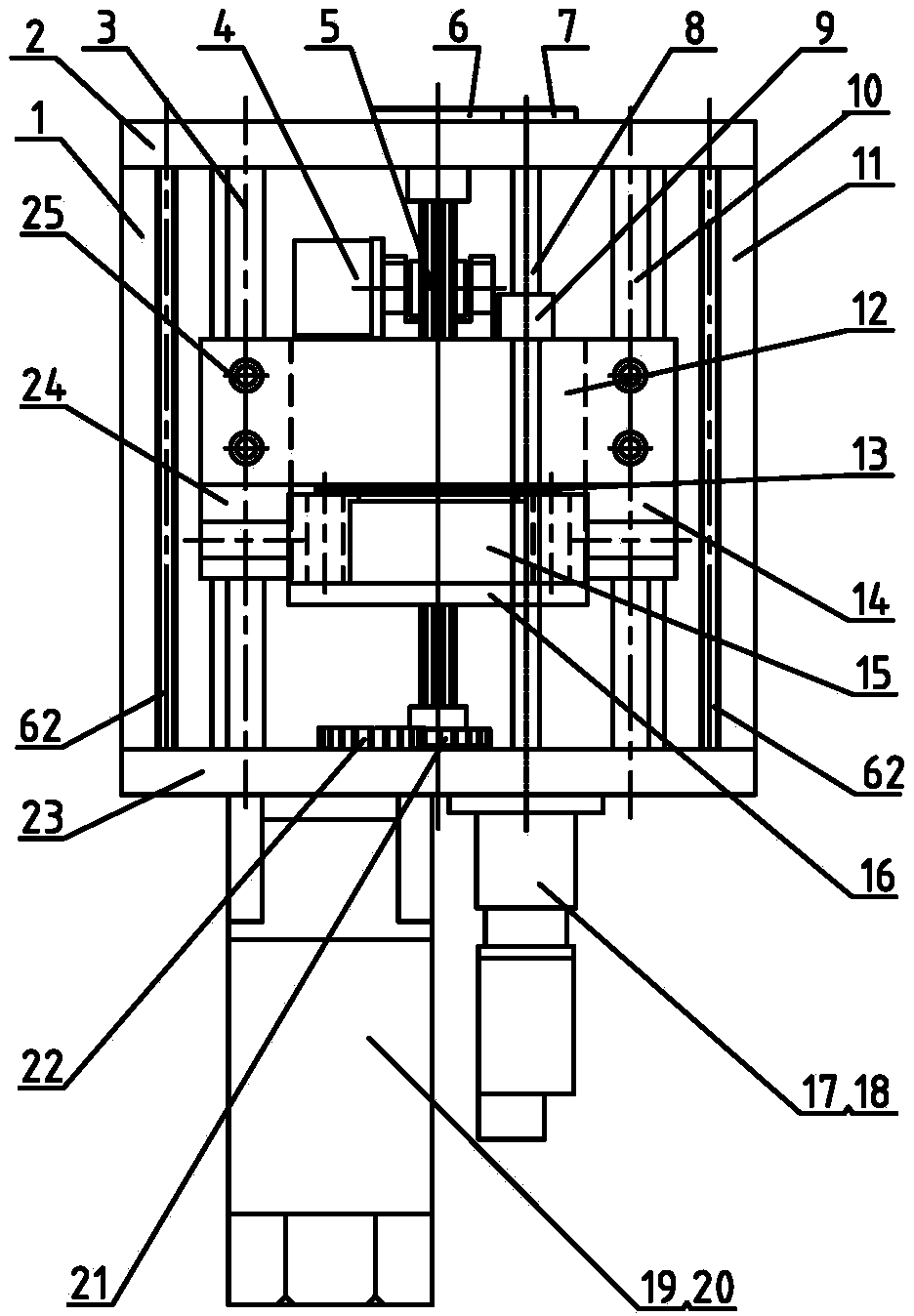

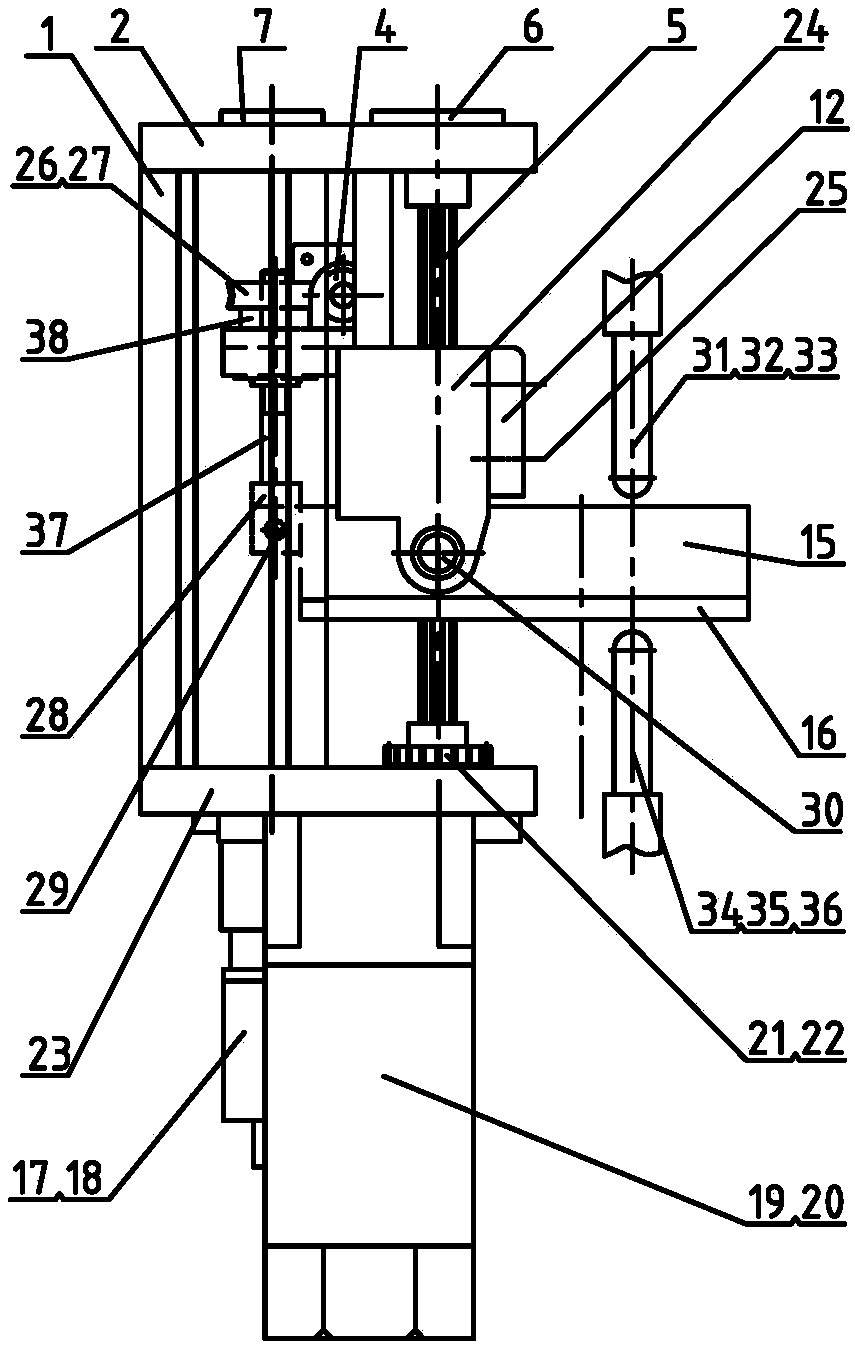

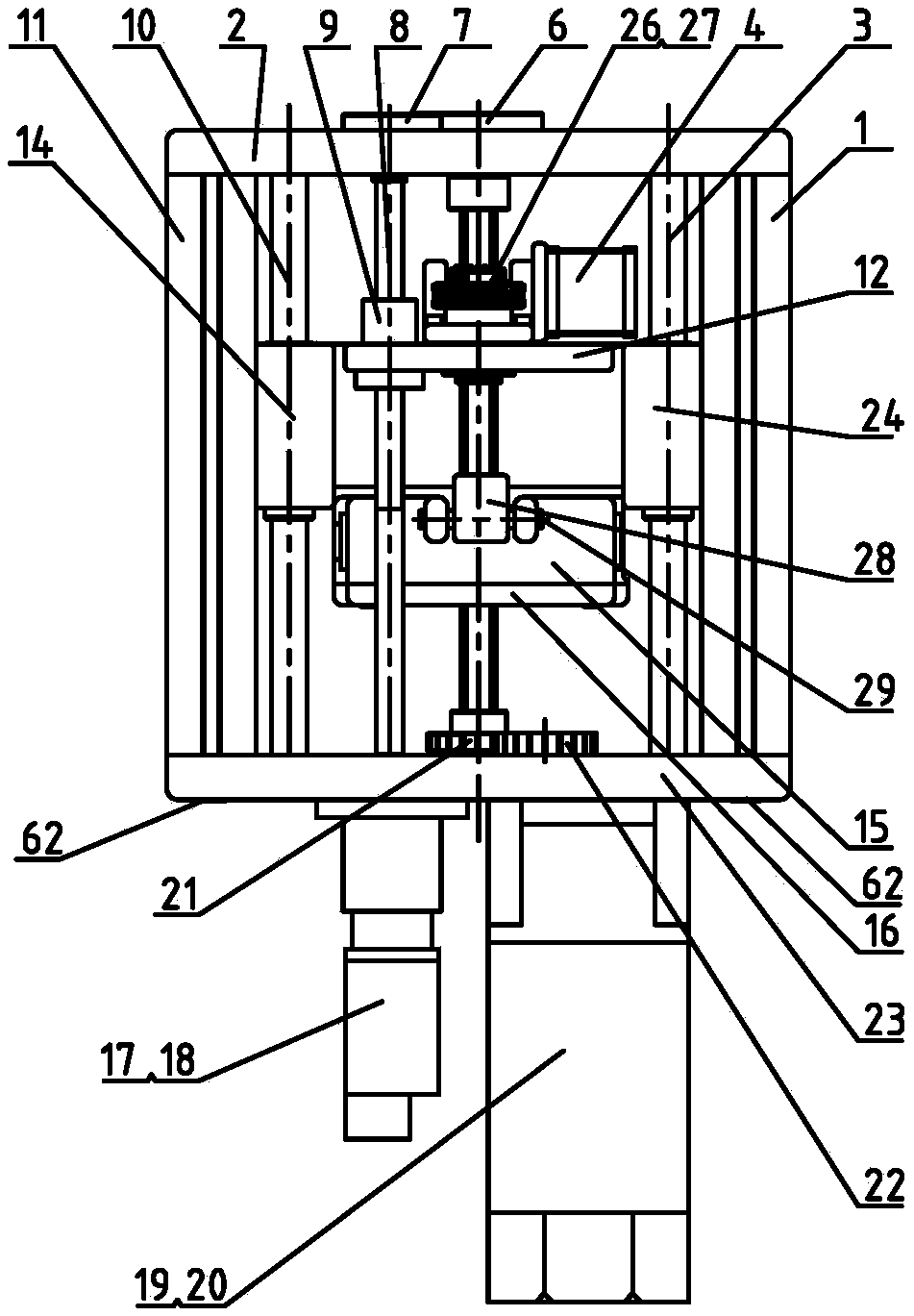

[0097] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0098] The invention relates to a single-working-end swing-type automatic electrode grinder applicable to automatic grinding of linear-moving electrodes and swing-moving electrodes in automatic welding tongs, manual welding tongs and fixed spot welding machines during the spot welding process . The grinder of the present invention has the following characteristics in the electrode grinding process: first, the positioning mechanism is used to realize the electrode grinding process as standard grinding; second, through the control of the servo motor, the grinding displacement can be realized and the control of the knife-eating speed during grinding; third, the incremental ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com