Roughing and finishing integrated hard alloy dry-cutting hob

A technology of hard alloy and hob, which is applied in the direction of metal processing equipment, gear tooth manufacturing equipment, gear teeth, etc., can solve the problems of low machining accuracy, high tool change cost, and low cutting efficiency, so as to improve the quality of grinding, Reduce tool change costs and improve cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

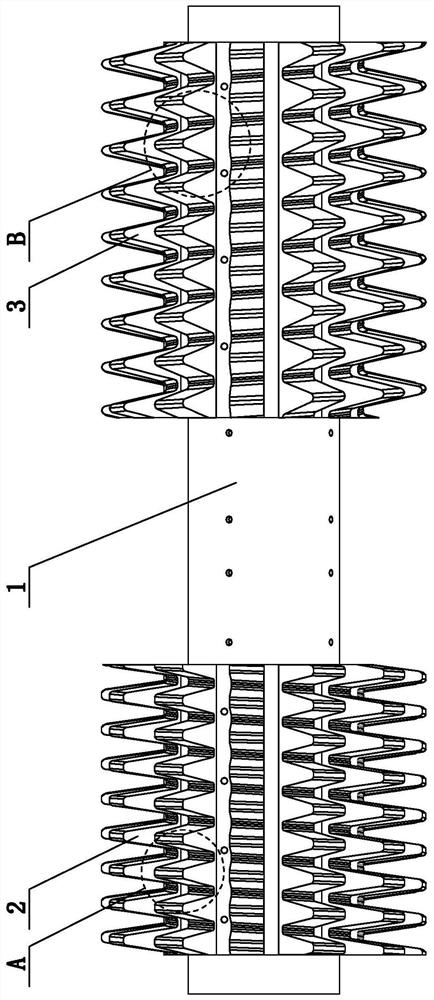

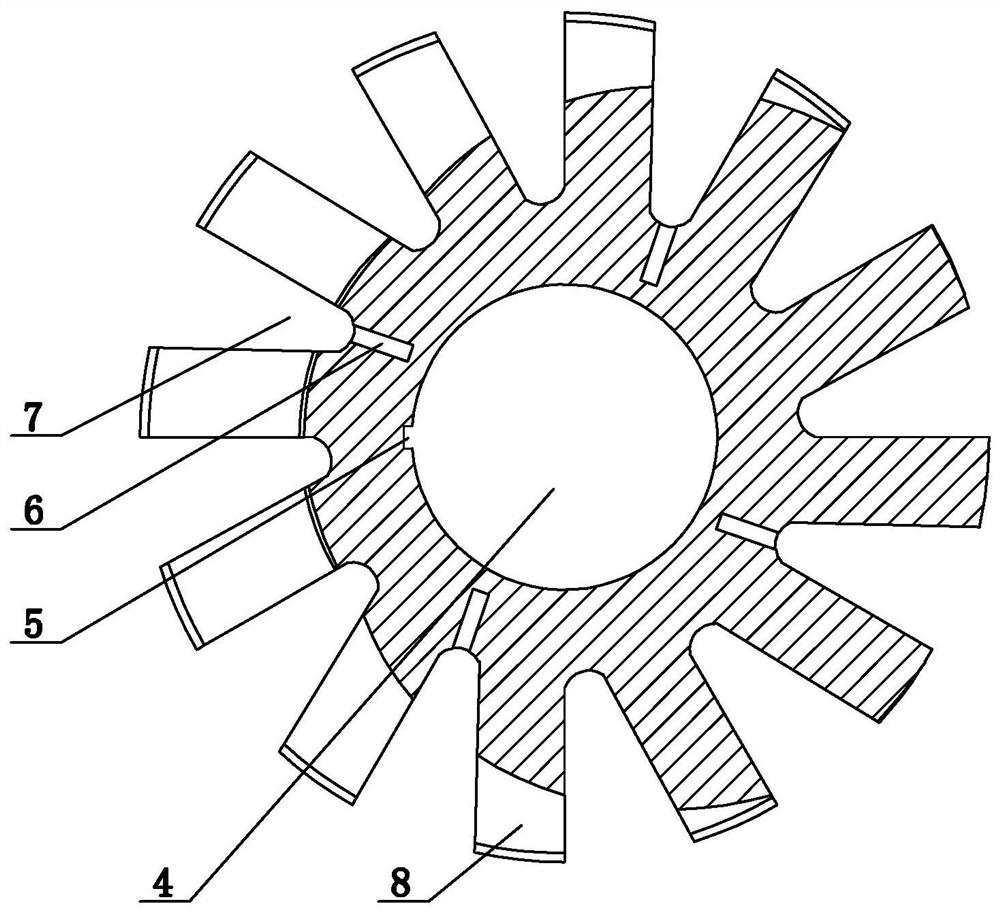

[0023] Specific implementation mode one: as Figure 1-Figure 5 As shown, this embodiment discloses a coarse and fine integrated cemented carbide dry cutting hob, including a hob main body 1, a rough machining hob set 3 and a finishing hob set 2, the center of the hob main body 1 is along the A hob positioning hole 4 is provided in the axial direction; the hob main body 1, the rough machining hob unit 3 and the finishing hob unit 2 are all made of hard alloy, and the inner wall of the hob positioning hole 4 is provided with a The keyway 5 connected by the key, the hob main body 1 is detachably and fixedly connected with the rough machining hob set 3 and the finish machining hob set 2 (the application of the finish machining hob set 2 can reduce or replace honing process, reduce gear processing time, reduce gear processing costs, and improve gear processing efficiency), the outer circular surface of the rough machining hob group 3 is evenly equipped with a plurality of V-shaped ...

specific Embodiment approach 2

[0024] Specific implementation mode two: as figure 1 , figure 2 and Figure 4 As shown, this embodiment is a further description of specific embodiment 1. The rough machining hob unit 3 is evenly distributed with a plurality of rough machining fixing bolt holes 9 in the radial direction, and the plurality of rough machining fixing bolt holes 9 9 are all arranged at the bottom of the corresponding V-shaped rough machining hob chip pocket 10; the finishing hob unit 2 is evenly arranged with a plurality of finishing bolt holes 6 along the radial direction, and the multiple finishing The fixing bolt holes 6 are all set at the bottom of the corresponding V-shaped finishing hob chip pocket 7 (with the functions of fixing the hob and transmitting torque, and at the same time, the user can customize the installation according to the required tool length and efficient tool shifting method The position of the hob can prolong the service life of the tool and improve the consistency of...

specific Embodiment approach 3

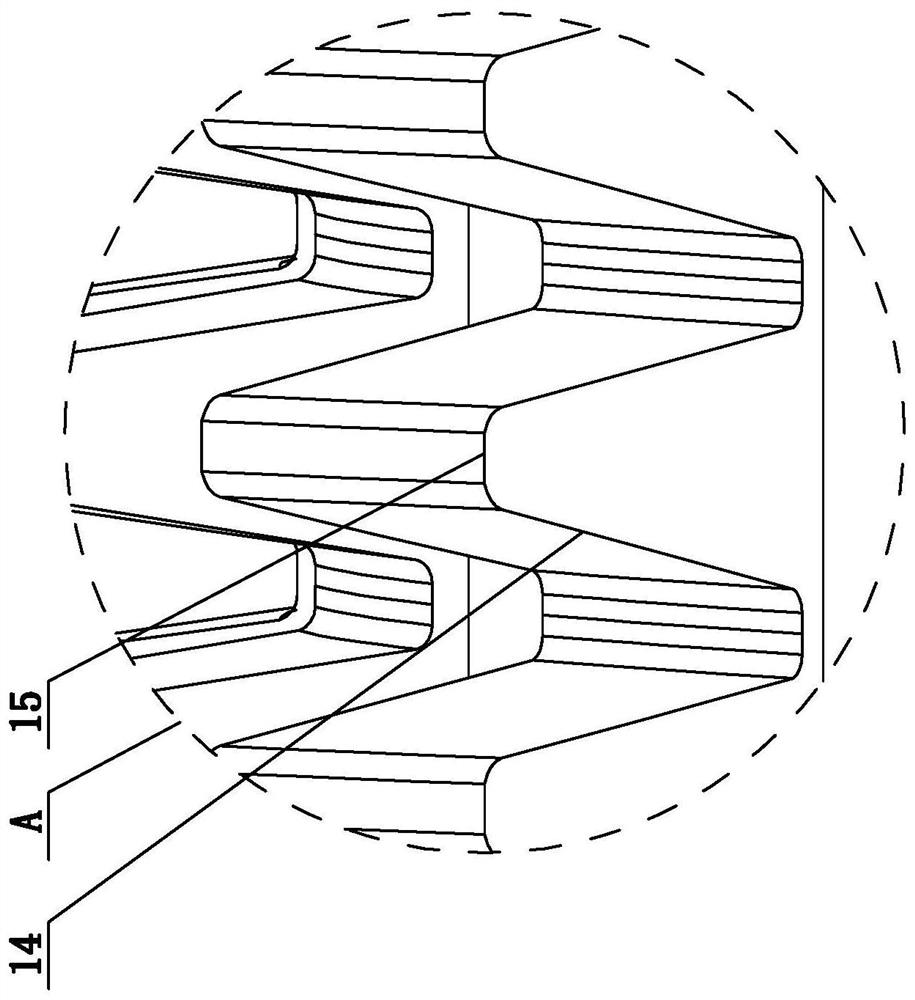

[0025] Specific implementation mode three: as figure 2 and Figure 4 As shown, this embodiment is a further description of specific embodiment 1 or 2. The opening angles of the V-shaped rough machining hob chip pocket 10 and the V-shaped finishing hob chip pocket 7 are both 14-16° , the formula for calculating the depth of the V-shaped rough machining hob chip pocket 10 and the depth of the V-shaped finishing hob chip pocket 7 is: Among them: H is the depth of 10 chip pockets of V-shaped rough machining hob or 7 depth of chip pocket of V-shaped finishing hob, h 0 is the full tooth height, k is the amount of shovel back, k 1 For the second shovel back, the V-shaped rough machining hob chip pocket and the V-shaped finishing hob chip pocket have the structural characteristics of large width and deep grooves, which can not only increase the inflow of compressed air, but also further improve the heat dissipation of cutting speed, and can expand the chip discharge channel, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com