Method and device for multi-line silicon chip cutting with free-solidified compound abrasives

A multi-wire cutting and composite abrasive technology, which is applied in grinding/polishing equipment, metal processing equipment, stone processing equipment, etc., can solve the problem of not meeting the development requirements of silicon wafers, making manufacturing technology more difficult, and affecting the effect of abrasives To achieve the effect of enhancing microscopic plastic cutting performance, reducing surface cracks, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

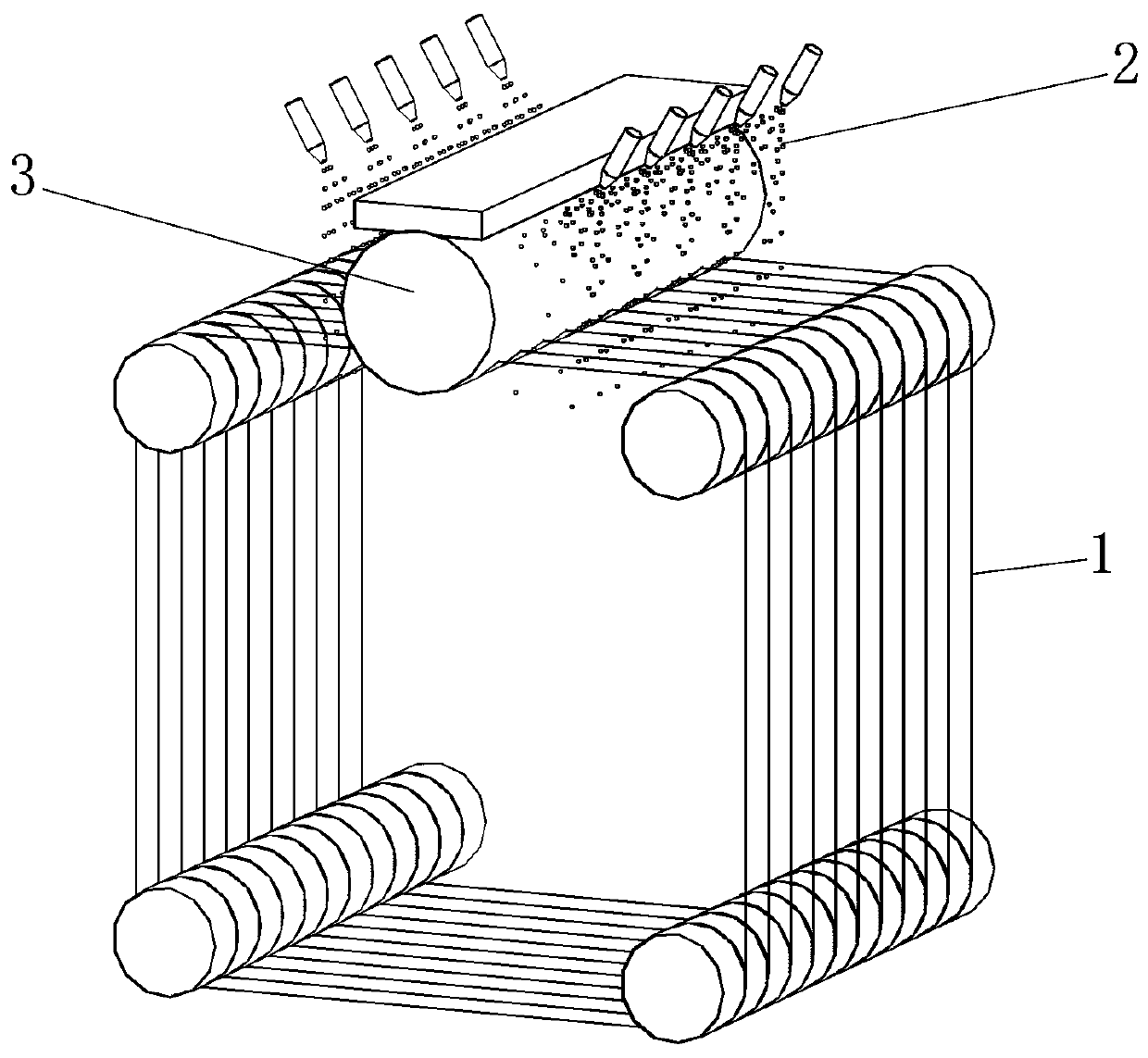

[0017] refer to figure 1 , a method for multi-wire cutting of silicon wafers with free-bonded composite abrasives, which includes sawing a silicon crystal ingot 3 by using a method of multi-wire cutting with fixed abrasives, and spraying the abrasive liquid 2 containing suspended diamond abrasive grains to the cutting area at the same time ; The metal wire 1 with diamond abrasive grains on the surface will bring the abrasive liquid 2 containing suspended diamond abrasive grains into the slit of the silicon ingot 3 during the wire walking process, forming free abrasive grains and consolidated abrasive grains to work together, The silicon crystal ingot 3 is sawed, and the silicon crystal ingot 3 is cut into several pieces in one process.

[0018] The free-bonded composite abrasive multi-wire cutting device for silicon wafers includes free abrasive multi-wire cutting equipment, and diamond abrasive grains are consolidated on the surface of all metal wires 1 of the free abrasive m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com