Distal end screw tap and application thereof

A kind of tap, the most advanced technology, applied in the advanced tap and its application field, can solve the problems of low tap life, tap breakage, and tool give-up phenomenon, achieve high reliability and stability, improve anti-twist breaking ability, anti-twist breaking The effect of increased ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

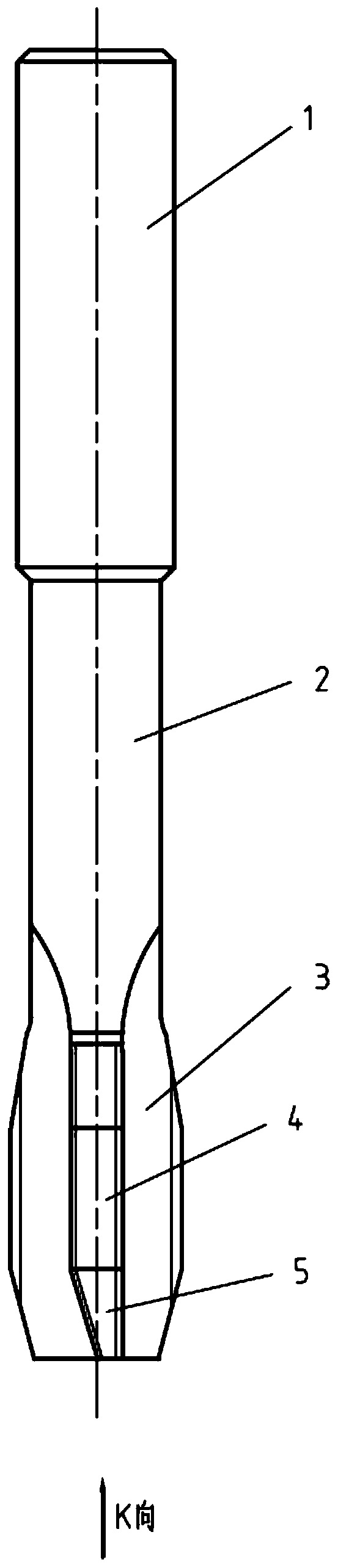

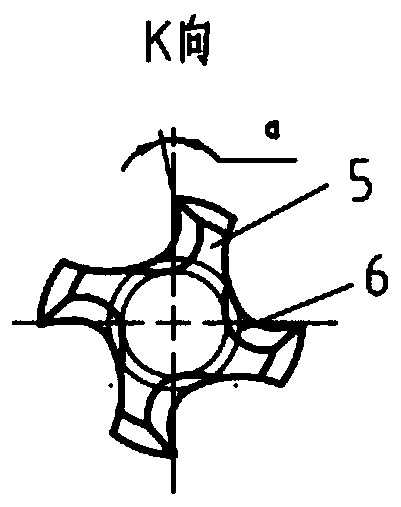

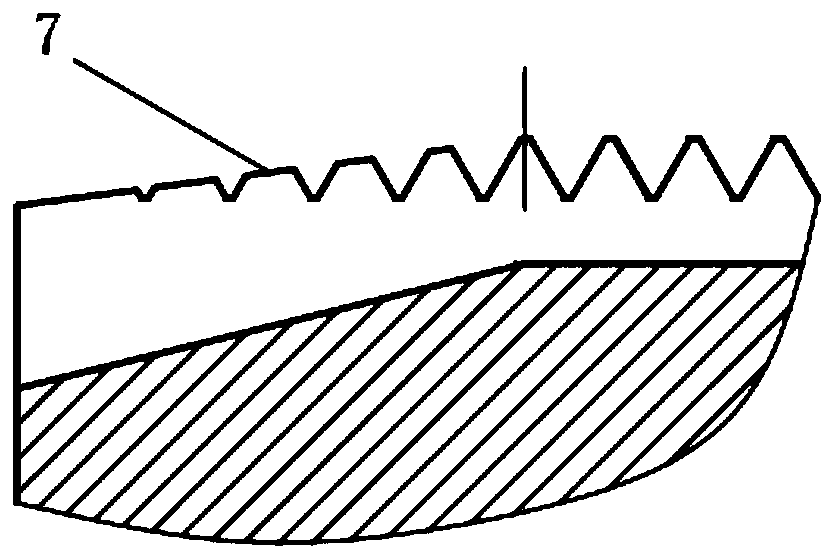

[0024] Such as Figure 1~2 As shown, the tip tap of the present invention includes a shank 1, a neck 2 and a working part. A core 6, a calibration part 4, a cutting part 5 and a chip flute 3 are processed on the working part, and the cutting part 5 is located at the center of the working part. At the front end, threads are processed on the calibration part 4 and the cutting part 5 . Improvements and innovations have been made mainly from the following three aspects, taking the M10 tip tap as an example to illustrate:

[0025] (1) Structural enhancement design

[0026] The enhancement design of the tap structure is mainly improved from three aspects. First of all, according to the selection standard for the number of tap flutes, for commonly used tap specifications M8-M14, the number of chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com