Anti-blocking star type cinder valve

A star-shaped ash unloading valve and anti-clogging technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of impeller blade wear, affecting work efficiency, unloader clogging, etc., to reduce cutting force, Improve efficiency and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

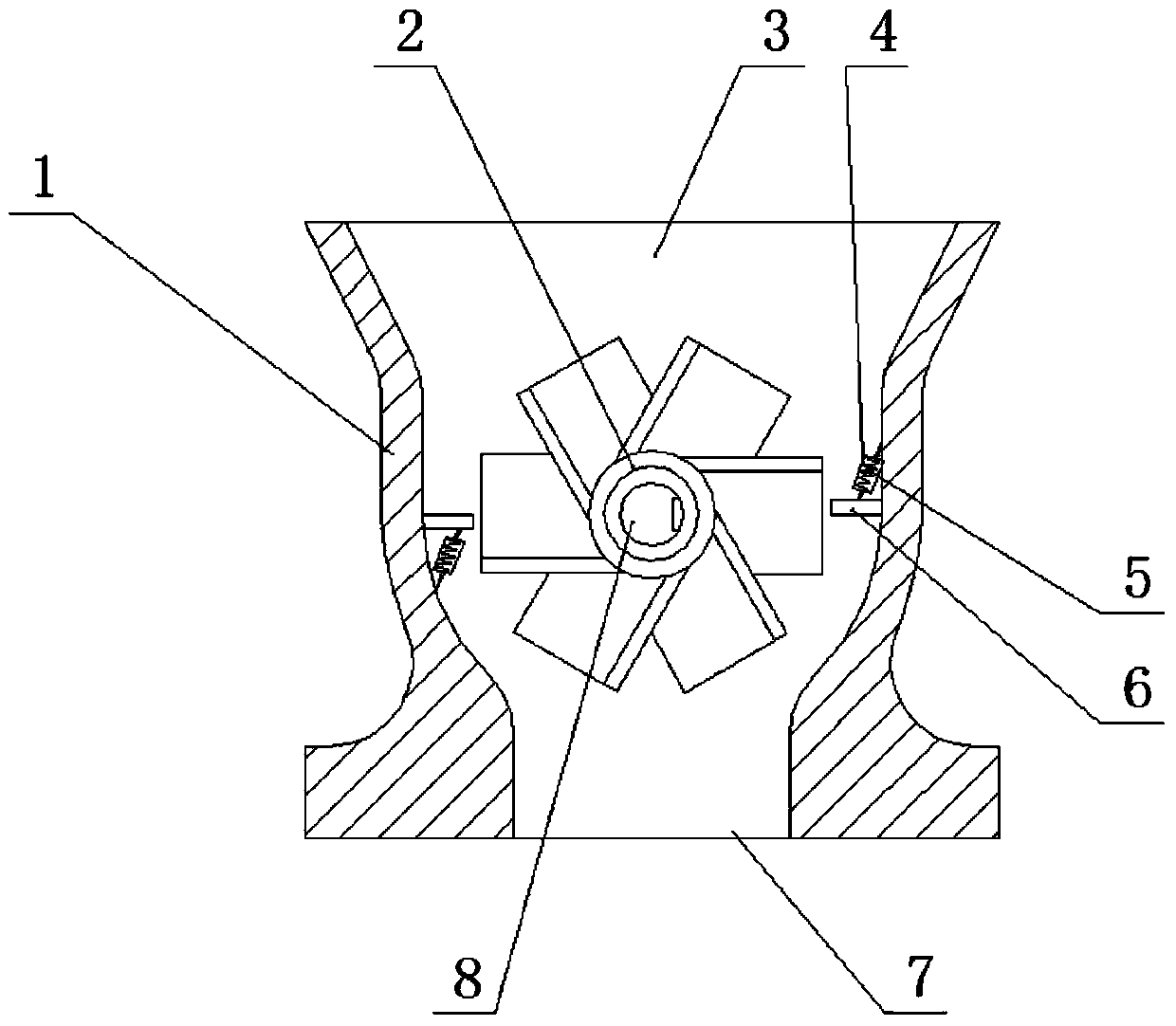

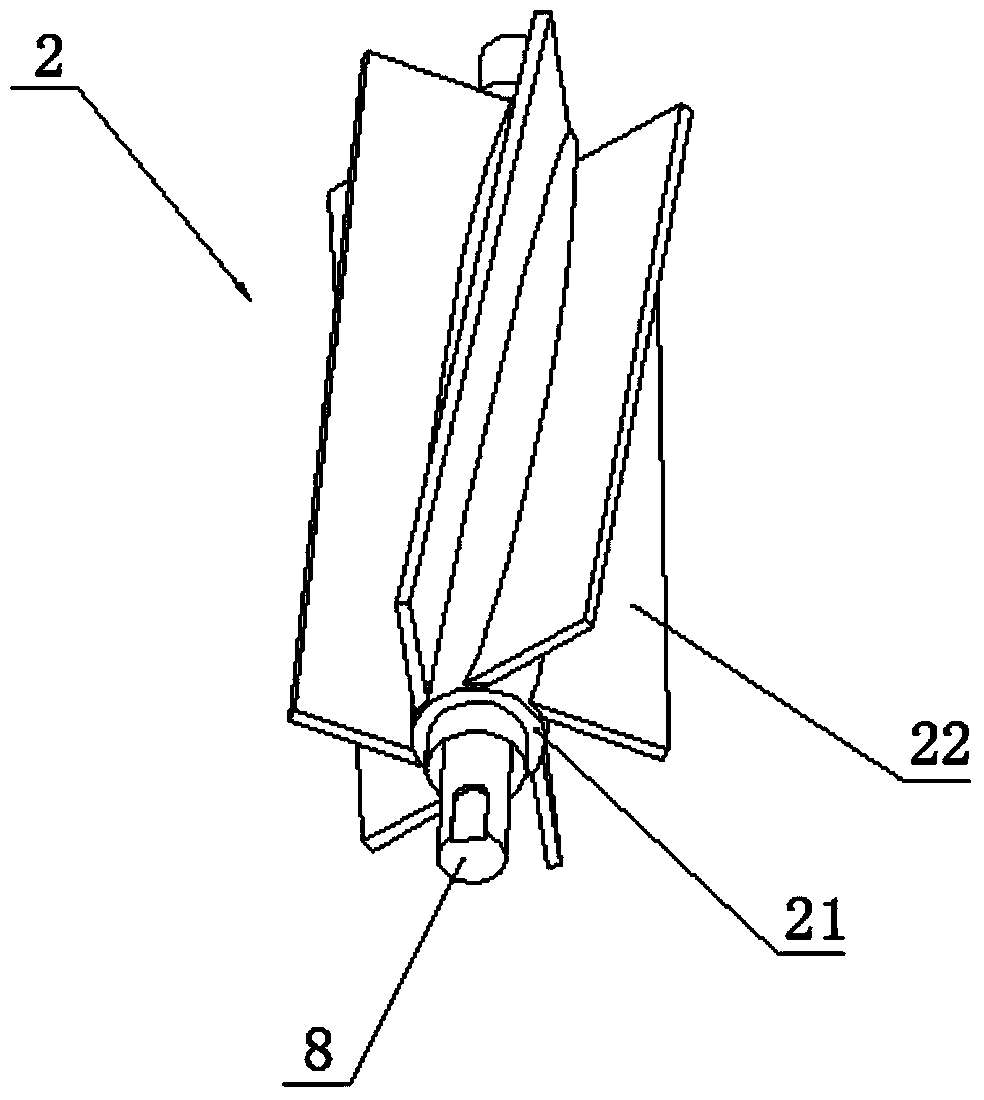

[0028] Such as figure 1 As shown, an anti-clogging star-shaped ash unloading valve includes: a housing 1, an impeller shaft 8, an impeller 2, a baffle 6 and a driving device (not shown in the figure), wherein: the upper end of the housing 1 is provided with a feeding port 3 and its lower end is provided with a discharge port 5, the impeller shaft 6 is rotatably set in the casing 1, and one end of it protrudes outside the casing 1 to connect with the driving device, which is composed of a motor and a reducer , the output end of the speed reducer is connected with the end of the impeller shaft 6 protruding from the casing to drive the rotation of the impeller shaft 6 . Such as figure 2 As shown, the impeller 2 includes blades 22 and a hub 21, and the blades 22 are six and evenly distributed on the outer wall circumference of the hub 21, and each blade 22 is offset by an angle relative to the axis of the hub 21, and the angle between the two is 6 °, the impeller 2 is fixedly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com