Patents

Literature

54results about How to "Uniform refractive index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

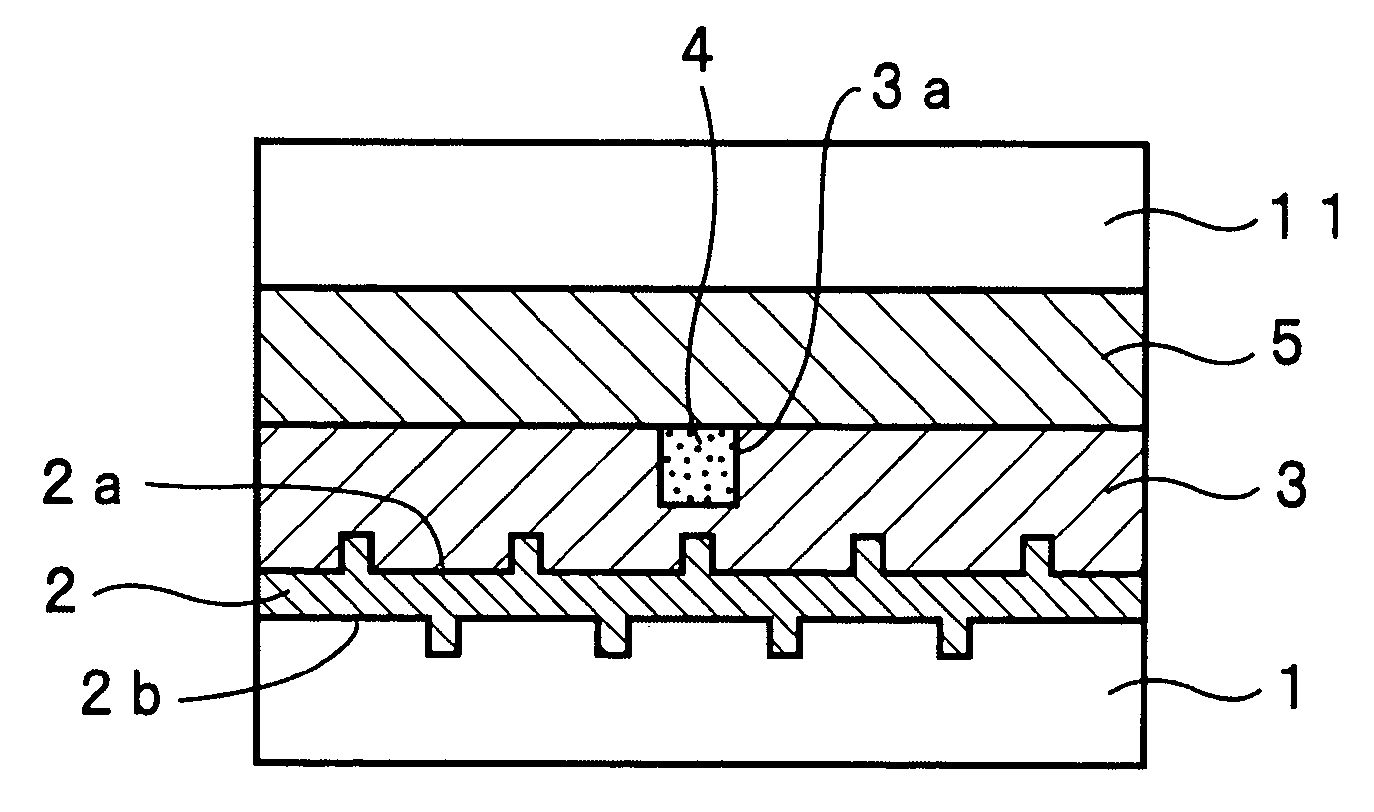

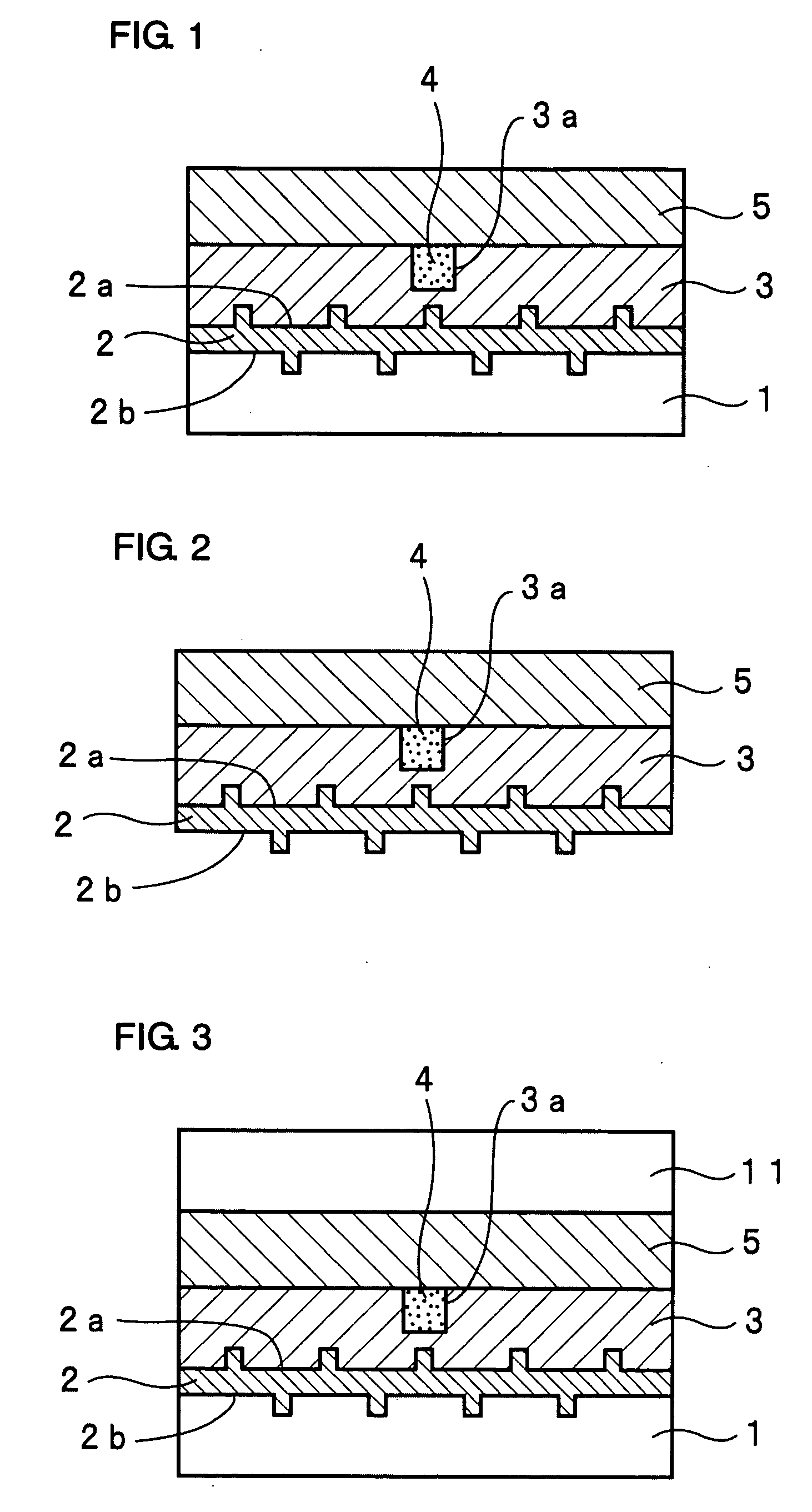

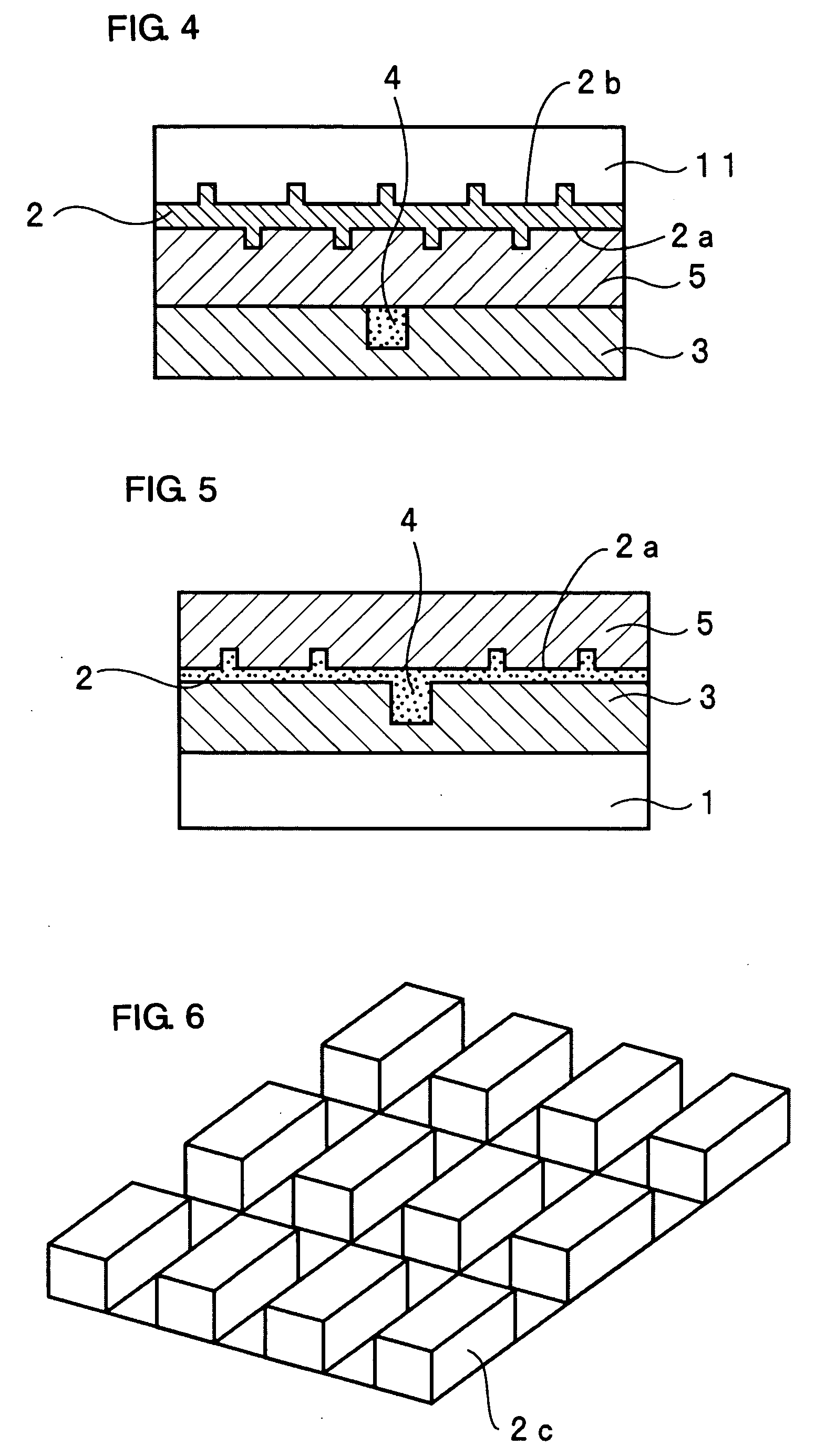

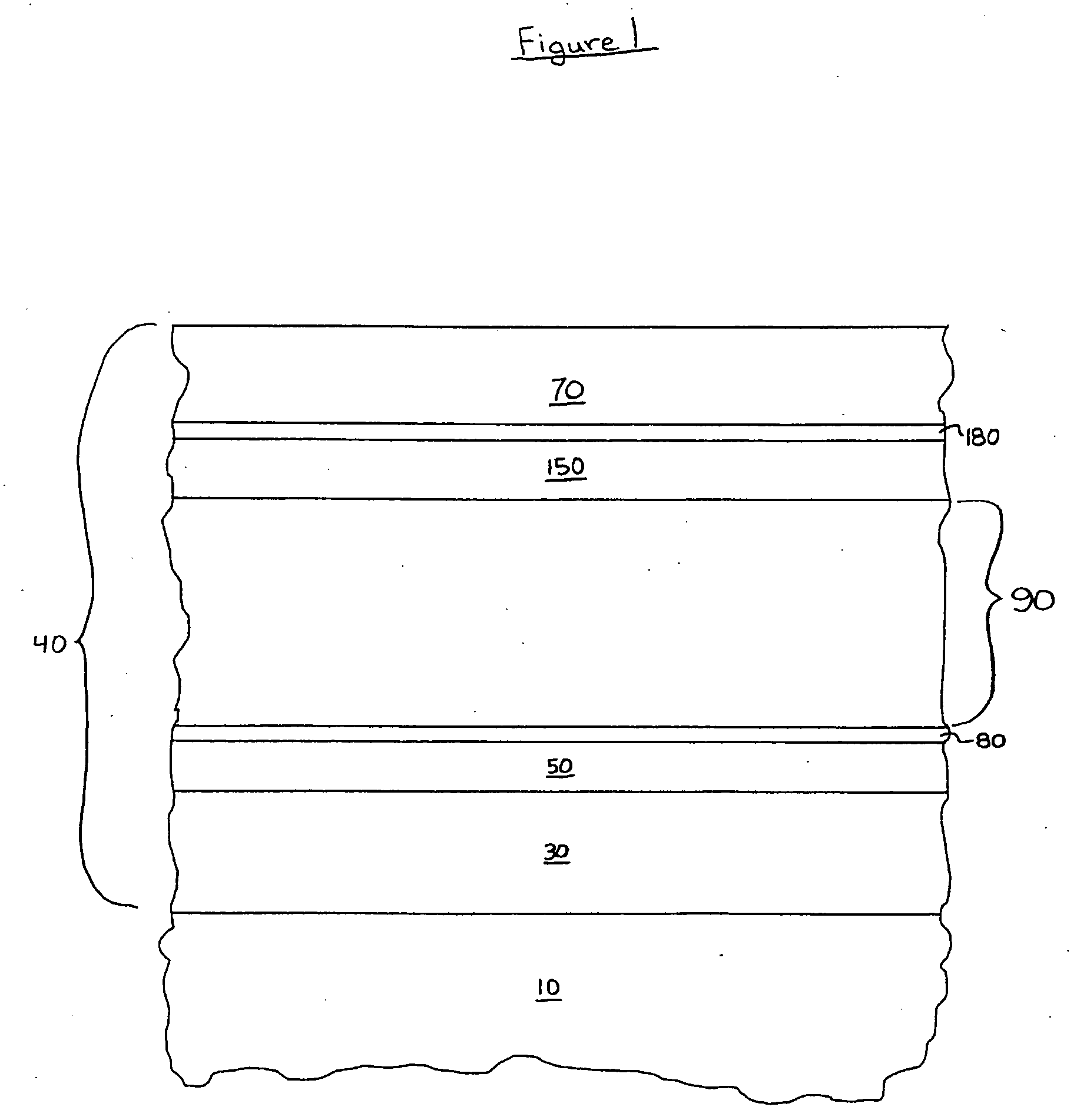

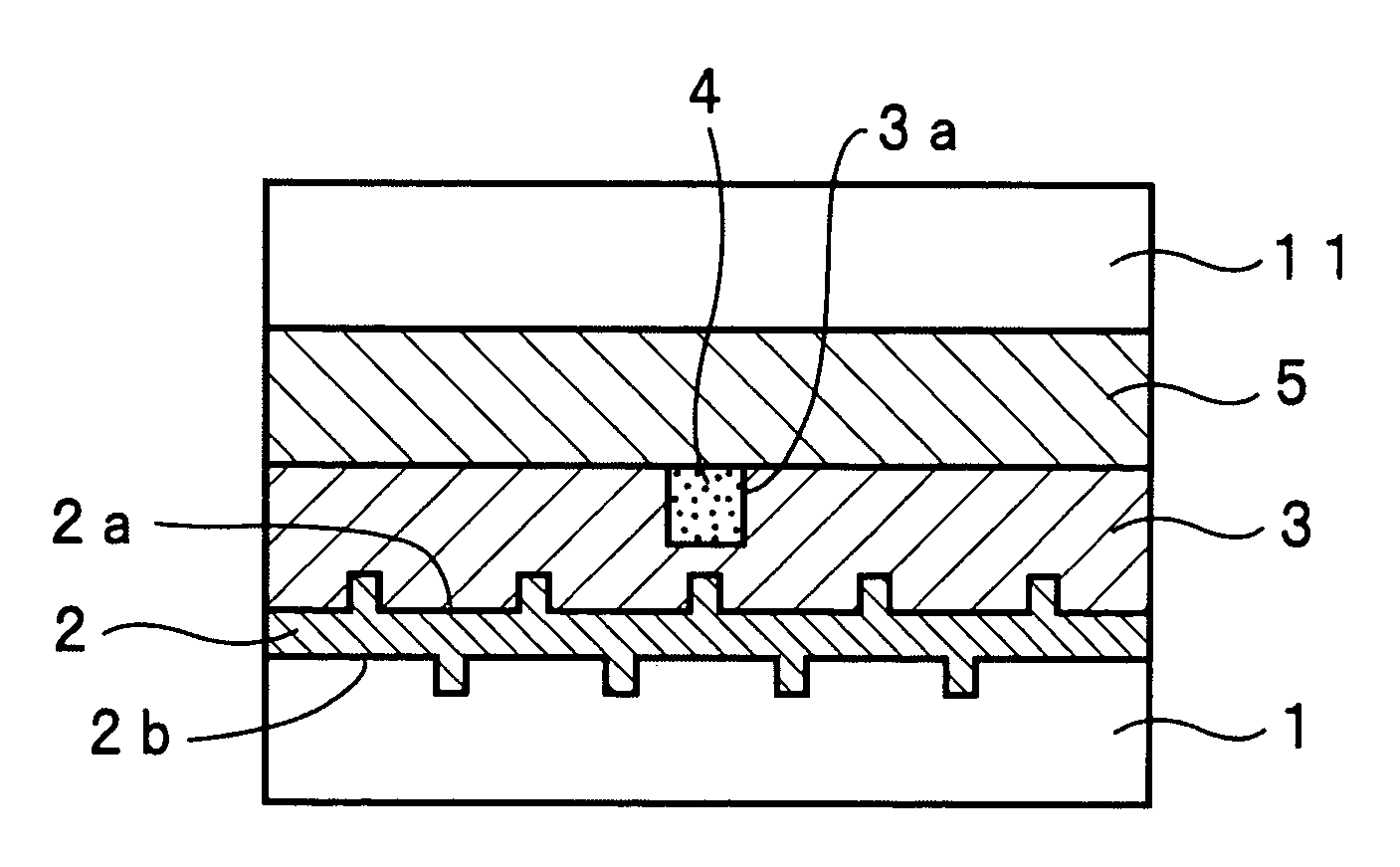

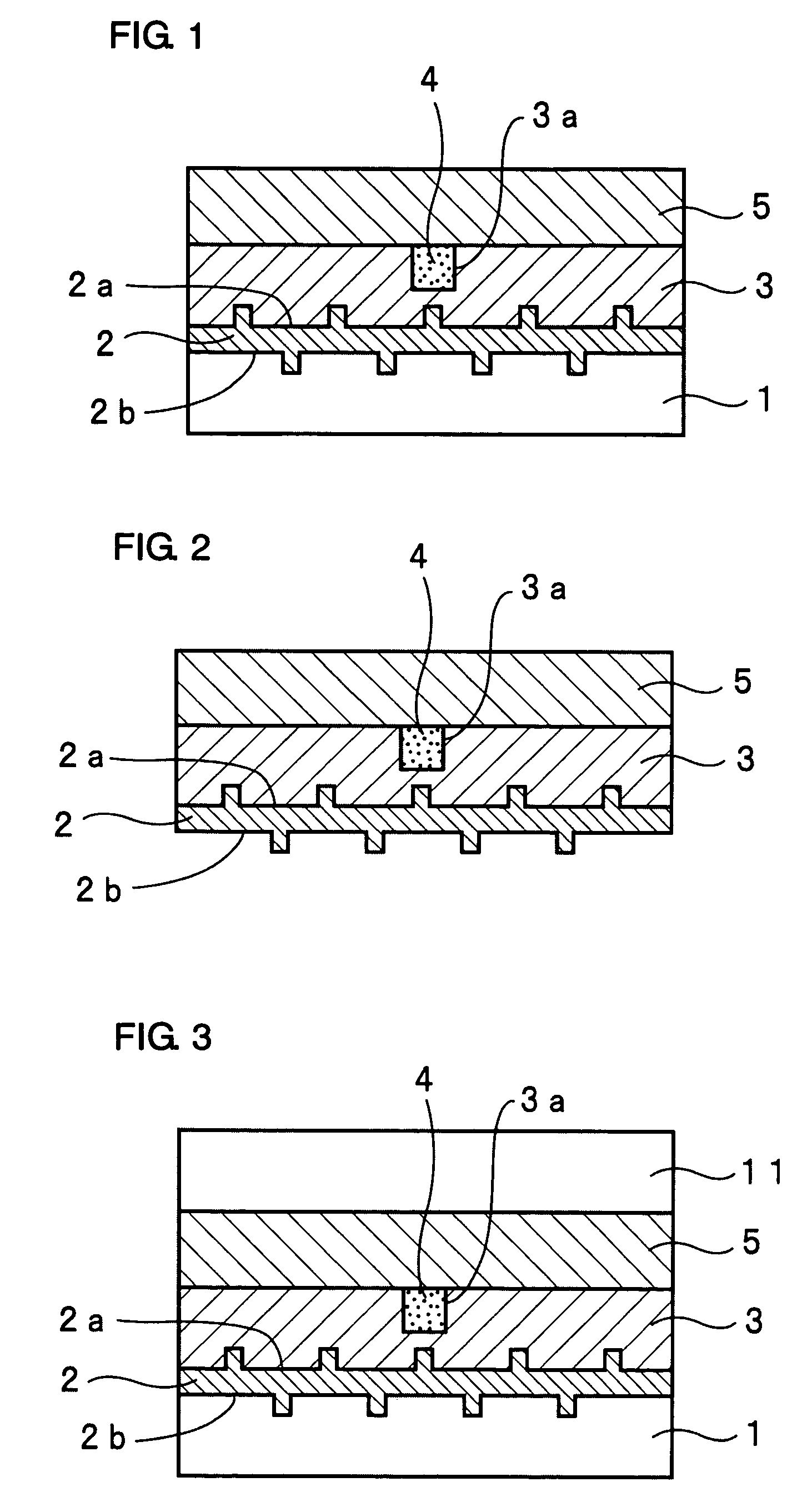

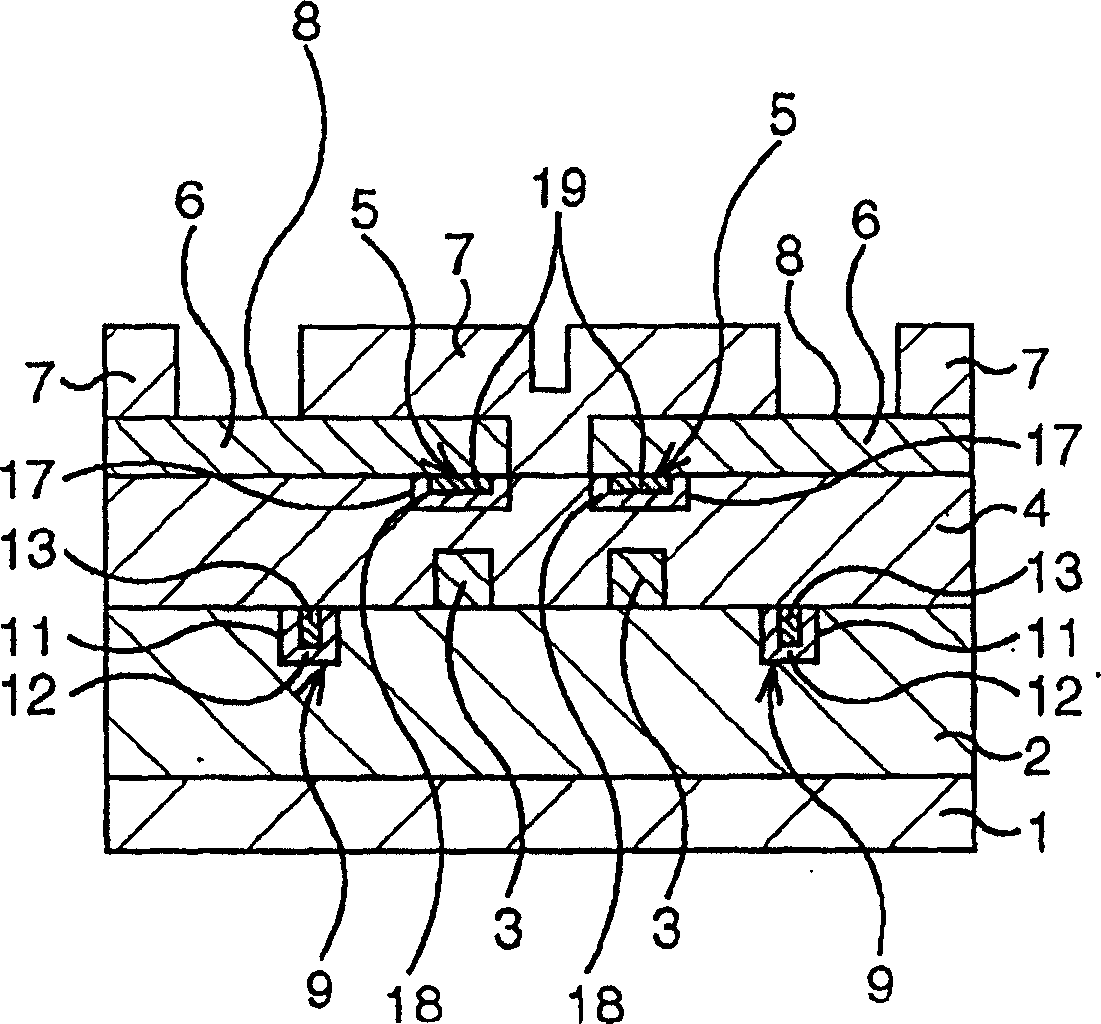

Optical waveguide and the method of fabricating the same

InactiveUS20050205885A1Uniform refractive indexAvoid enteringSolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsWaveguide

Disclosed herein is an optical waveguide comprising a core layer to be an optical waveguide region, an upper clad layer covering the core layer and a lower clad layer, characterized in that an ultraviolet control region for preventing ultraviolet light from entering is provided at any one location of under the lower clad layer, on an interface of the lower clad layer and the upper clad layer, and on the upper clad layer. And a method of fabricating this optical waveguide is also disclosed.

Owner:SANYO ELECTRIC CO LTD

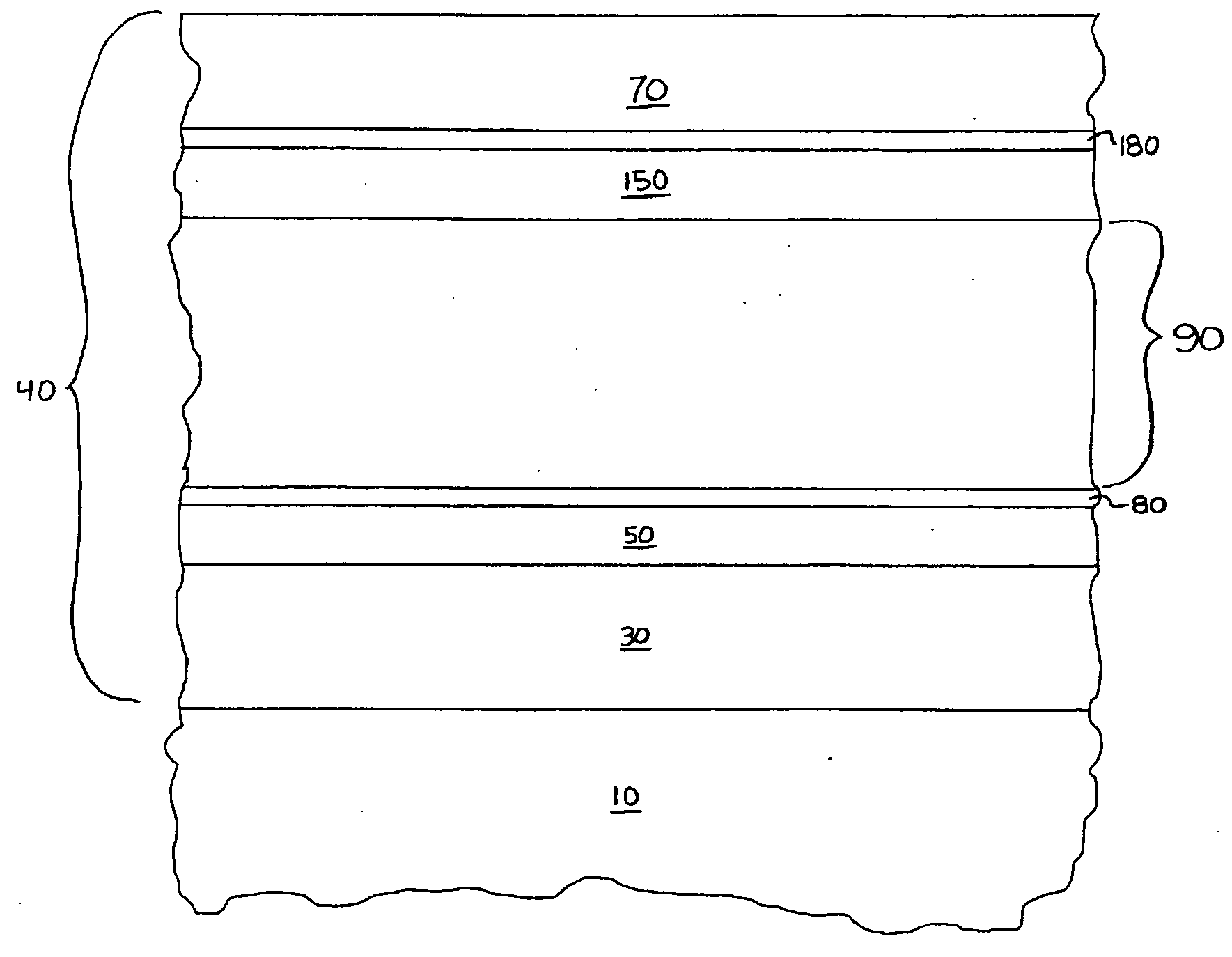

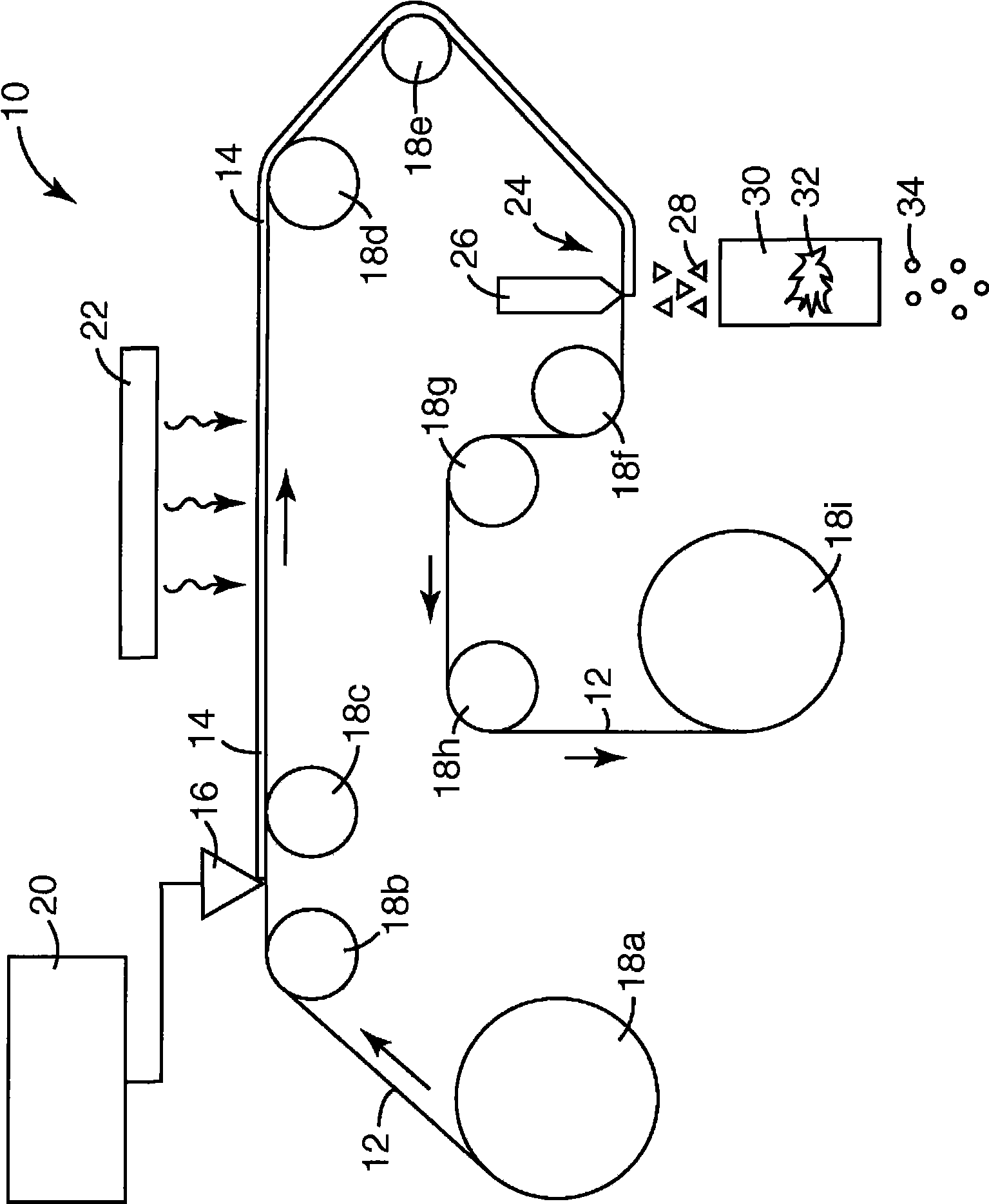

Concentration-modulated coatings

ActiveUS20050026002A1Low-emissivity coatingUniform refractive indexCellsVacuum evaporation coatingLow emissivityReflective layer

The invention provides a substrate bearing a low-emissivity coating. The low-emissivity coating comprises at least one graded film region. In certain embodiments, at least one graded film region is provided between the two infrared-reflective layers of a double-type low-emissivity coating. The graded film region has a substantially continuously decreasing concentration of a first dielectric material and a substantially continuously increasing concentration of a second dielectric material. Also provided are methods of depositing such low-emissivity coatings and substrates bearing these coatings.

Owner:CARDINAL CG

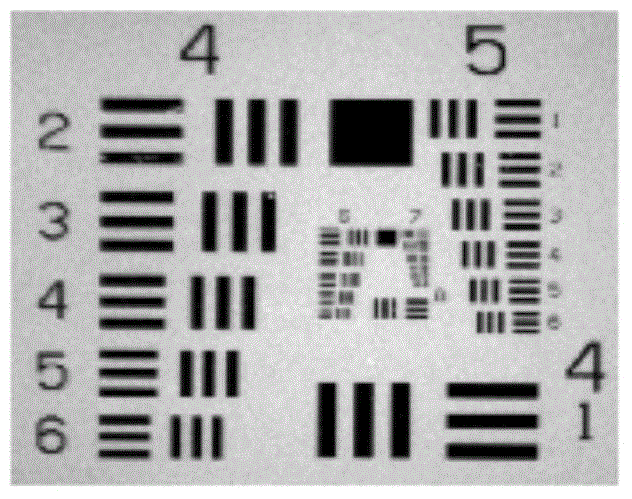

Liquid set for dyeing biological tissue sample slices

InactiveCN106053187AEnsure transparencyTissue cell structure is clearPreparing sample for investigationBiological tissueChemistry

The invention discloses a liquid set for dyeing biological tissue sample slices. The liquid set comprises a slice de-waxing liquid, which comprises D-limonene, methyl cyclohexane, and a surfactant; a hematoxylin dyeing auxiliary liquid, which comprises hematoxylin, anhydrous ethanol, purified water, periodic acid, glycerol, critic acid, and aluminum potassium sulfate; a differentiation liquid, which comprises anhydrous ethanol, purified water, and hydrochloric acid; a bluing liquid, which comprises purified water and a potassium hydroxide water solution; an eosin dyeing liquid, which comprises water soluble eosin, purified water, anhydrous calcium chloride, and a hydrochloric acid water solution; and a slice transparent liquid, which comprises D-limonene, isopropanol, and a surfactant. The provided dyeing liquid set can be used as an environment-friendly pathology / histology reagent for processing tissue samples in pathology department of various hospitals and scientific research institutions, and can be applied to normal pathological diagnosis, immunologic tissue chemical diagnosis technology, molecular biology diagnosis technology, and the effect of tissue processing is better than that of conventional technologies.

Owner:北京九州柏林生物科技有限公司

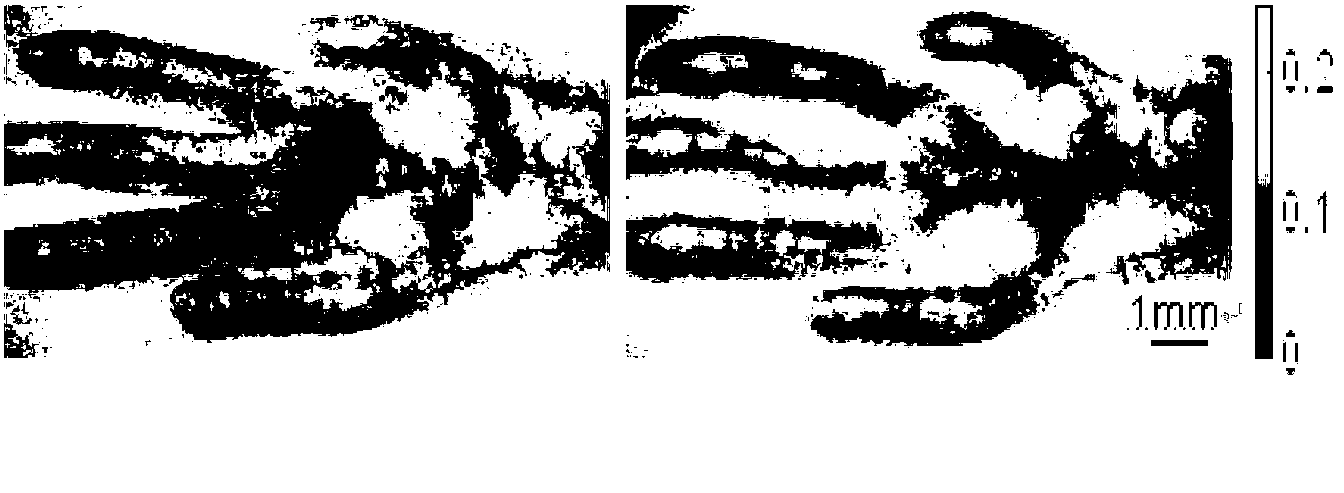

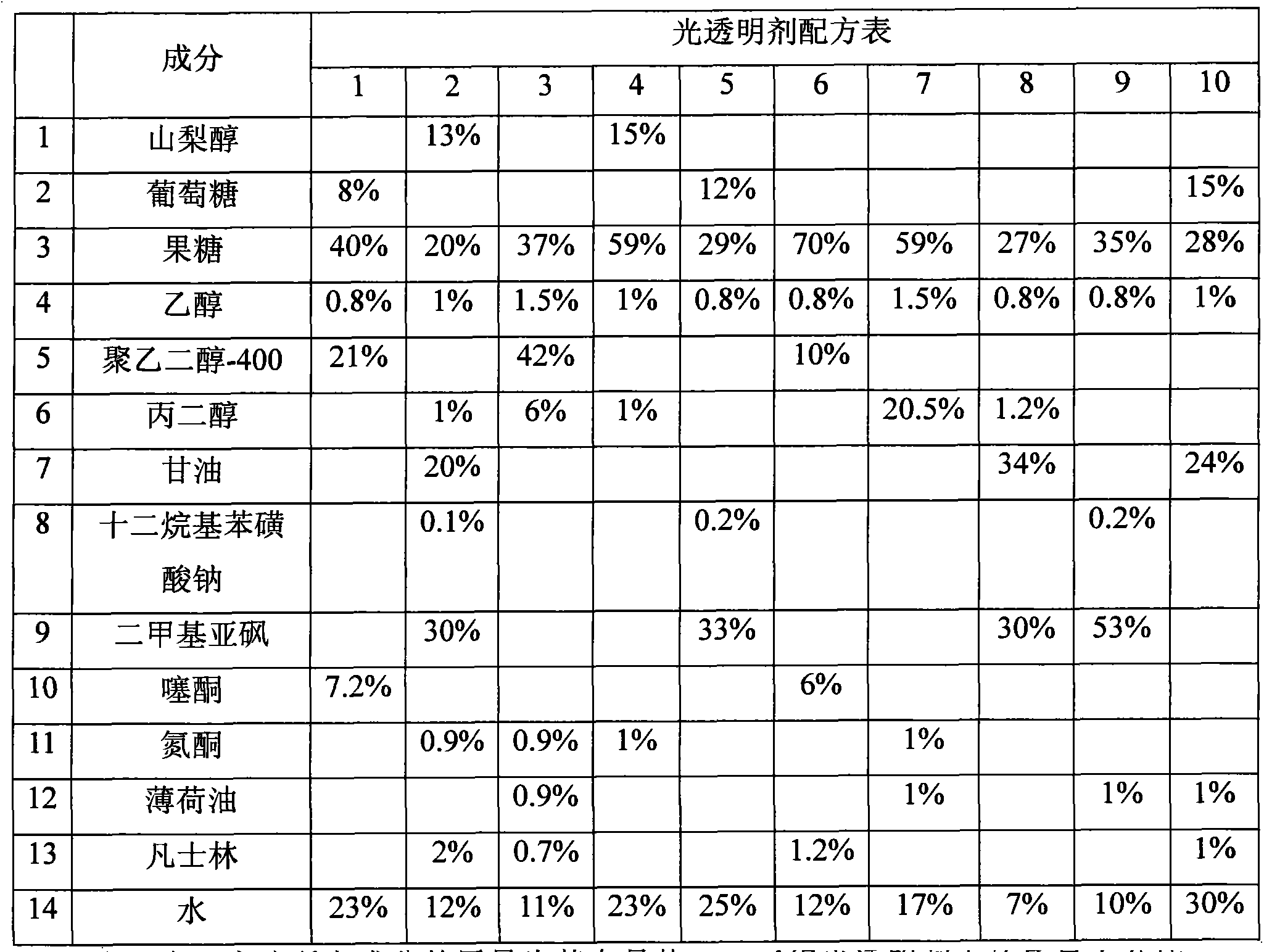

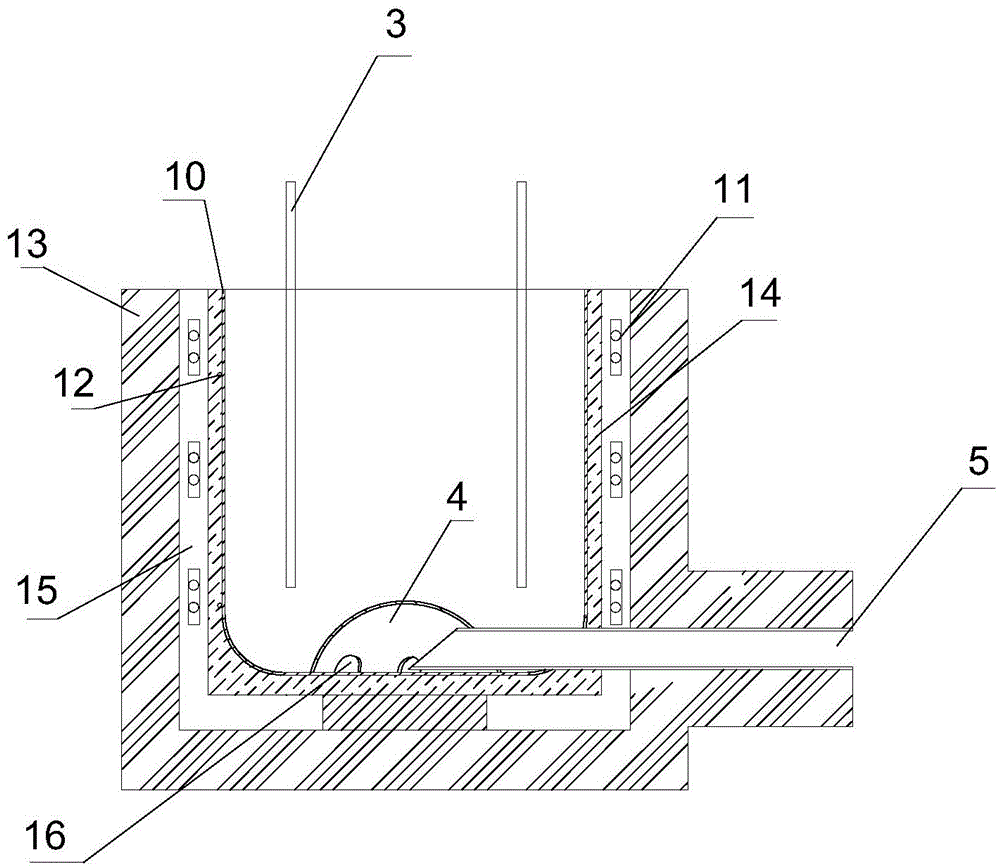

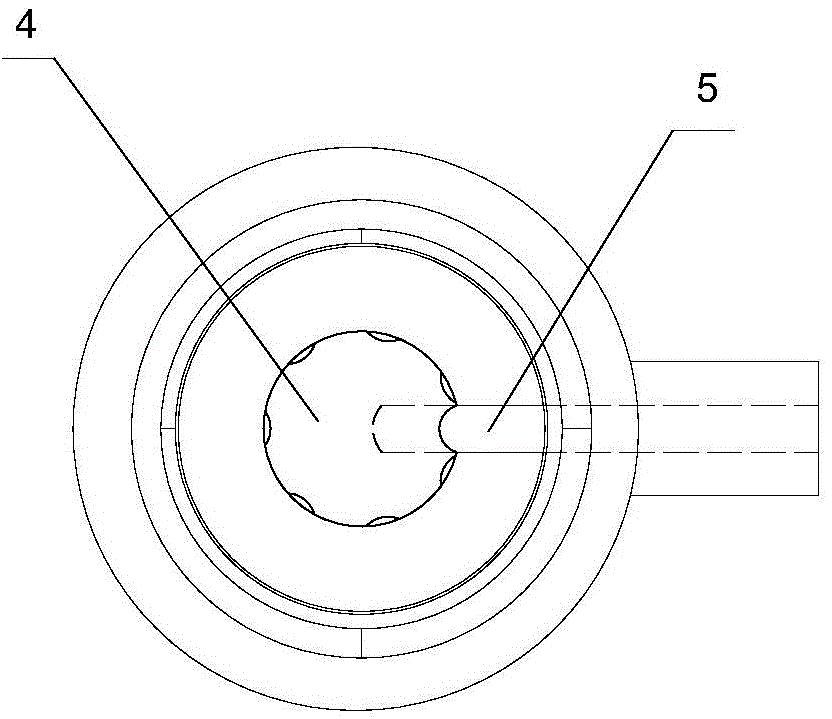

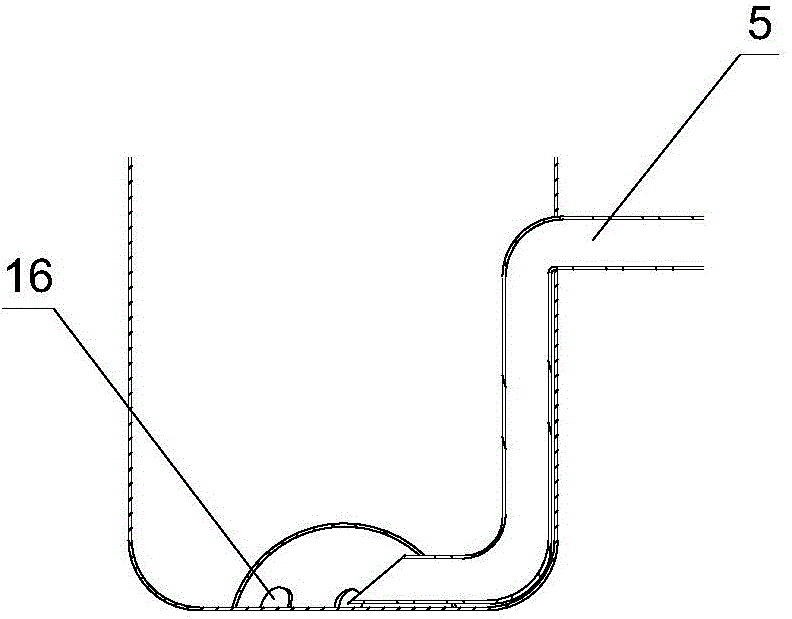

Footpad skin tissue optical clearing agent

InactiveCN103263678AReduce scatterUniform refractive indexIn-vivo testing preparationsWhite petrolatumOptical clearing

The invention discloses a footpad skin tissue optical clearing agent, which includes fructose, ethanol, water, and at least three of the following substances: polyethylene glycol-400, sorbitol, glucose, propylene glycol, glycerol, sodium dodecyl benzene sulfonate, dimethyl sulfoxide, butylbenisothiazolene, azone, peppermint oil and petroleum jelly, wherein the mass percentage of fructose in the footpad skin tissue optical clearing agent is 20%-75%, the mass percentage of ethanol in the footpad skin tissue optical clearing agent is 0.8%-1.5%, the mass percentage of water in the footpad skin tissue optical clearing agent is 7%-30%, and the balance of other substances. The present invention acts on the footpad skin tissue, so that the refractive index in the tissue can be quickly uniform, the scattering in the tissue is reduced, the tissue becomes transparent to light, imaging depth is improved, and a new method is provided to obtain information of skin blood vessels and blood flows.

Owner:HUAZHONG UNIV OF SCI & TECH

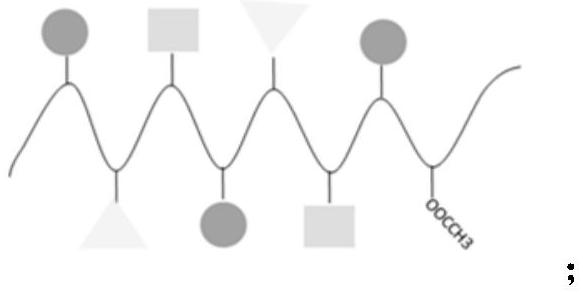

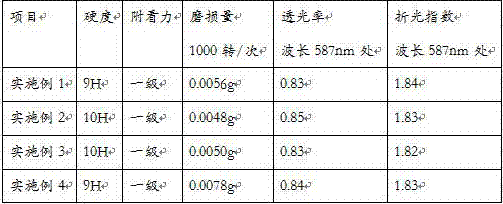

High-performance adhesive for optical communication devices and preparation method thereof

InactiveCN105441001AExcellent adhesionIncrease responsivenessMacromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention discloses a high-performance adhesive for optical communication devices and a preparation method thereof, relating to the technical field of high-polymer materials. The high-performance adhesive for optical communication devices is prepared from the following raw materials in parts by mass: 40-90 parts of cationic polymer resin, 2-30 parts of free radical photopolymer resin, 2-20 parts of polylol, 0.5-10 parts of photoinitiator, 0.05-5 parts of thermal initiator, 0.05-2 parts of coupling agent, 0.01-1 part of polymerization inhibitor and 0-10 parts of other assistants. The preparation method comprises the following steps: first mixing, second mixing and compound mixing. The high-performance adhesive for optical communication devices has the characteristics of quick curing, consistent refractivity with glass, favorable light transmittance, excellent adhesion force, high Tg, low shrinkage, high stability, excellent constructability, simple operability and the like, and can be applied to chips or bare fibers in optical communication industry and fixed in a V groove to be bonded and fixed with the cover plate.

Owner:深圳市浩力新材料技术有限公司

Glass melting device and melting method therefor

ActiveCN104926081AAffects fluctuations in melting qualityExtended service lifePot furnacesGlass furnace apparatusCrucibleRefractive index

The present invention provides a melting device for melting glass complex powder into high-quality molten glass and a melting method therefor. The glass melting device comprises an outer crucible, a bubbler tube, an discharge tube and a heating device, and further comprises an inner crucible with a convex curved surface body structure, wherein the bubbler tube is inserted into the outer crucible; the inner crucible is arranged on the bottom in the outer crucible and a plurality of through holes are formed inthe convex curved surface of the inner crucible. By changing the structures of devices such as the outer crucible, the inner crucible, the bubbler tube, the discharge tube and the like, the glass melting device can improve a flow path of the molten glass, optimizes the whole flow and residence time, effectively reduces an area in which the molten glass flows slowly around the inner crucible, improves the residence time concentration degree of the molten glass in the melting device and improves the uniformity of the glass components, thereby ensuring physical and chemical performances such as the refractive index, the the Abbe number and the like of a glass product to be more uniform and stable.

Owner:CDGM OPTICAL GLASS

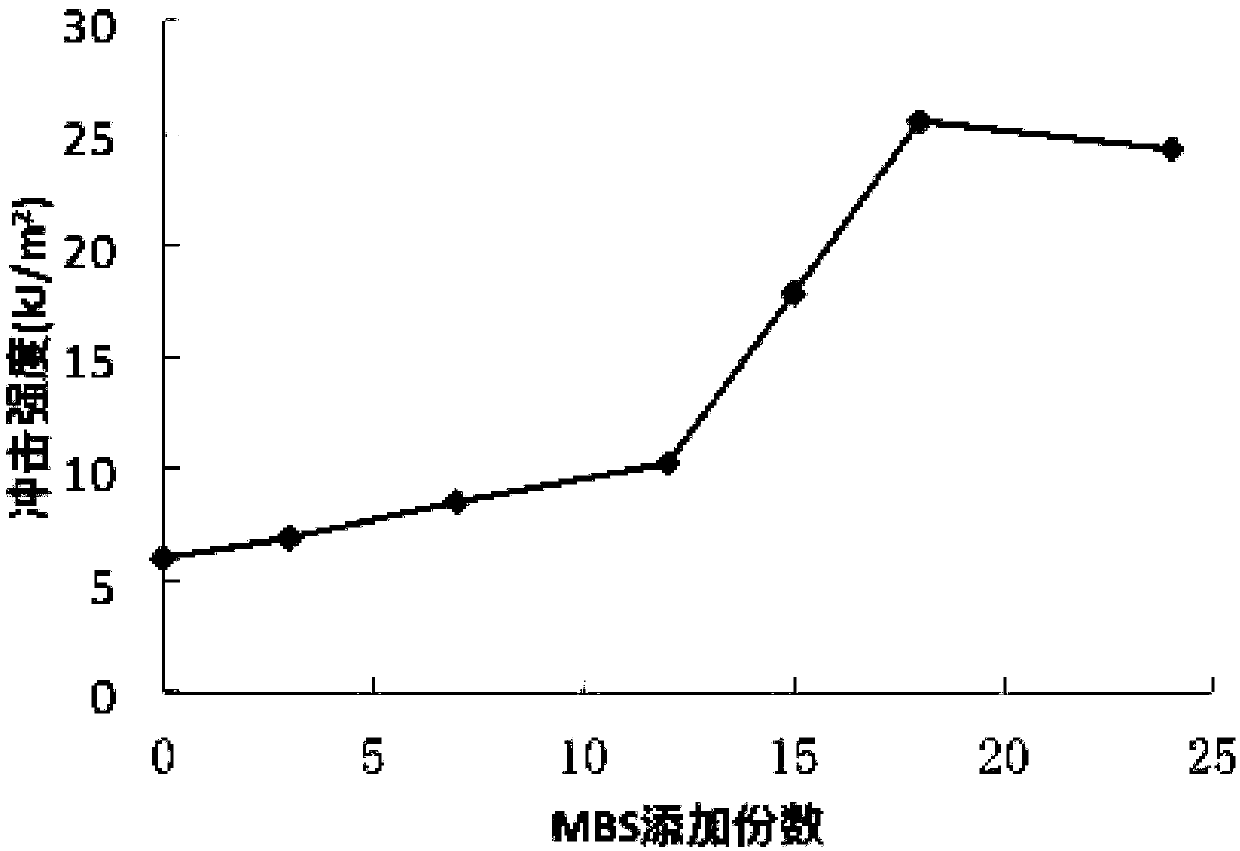

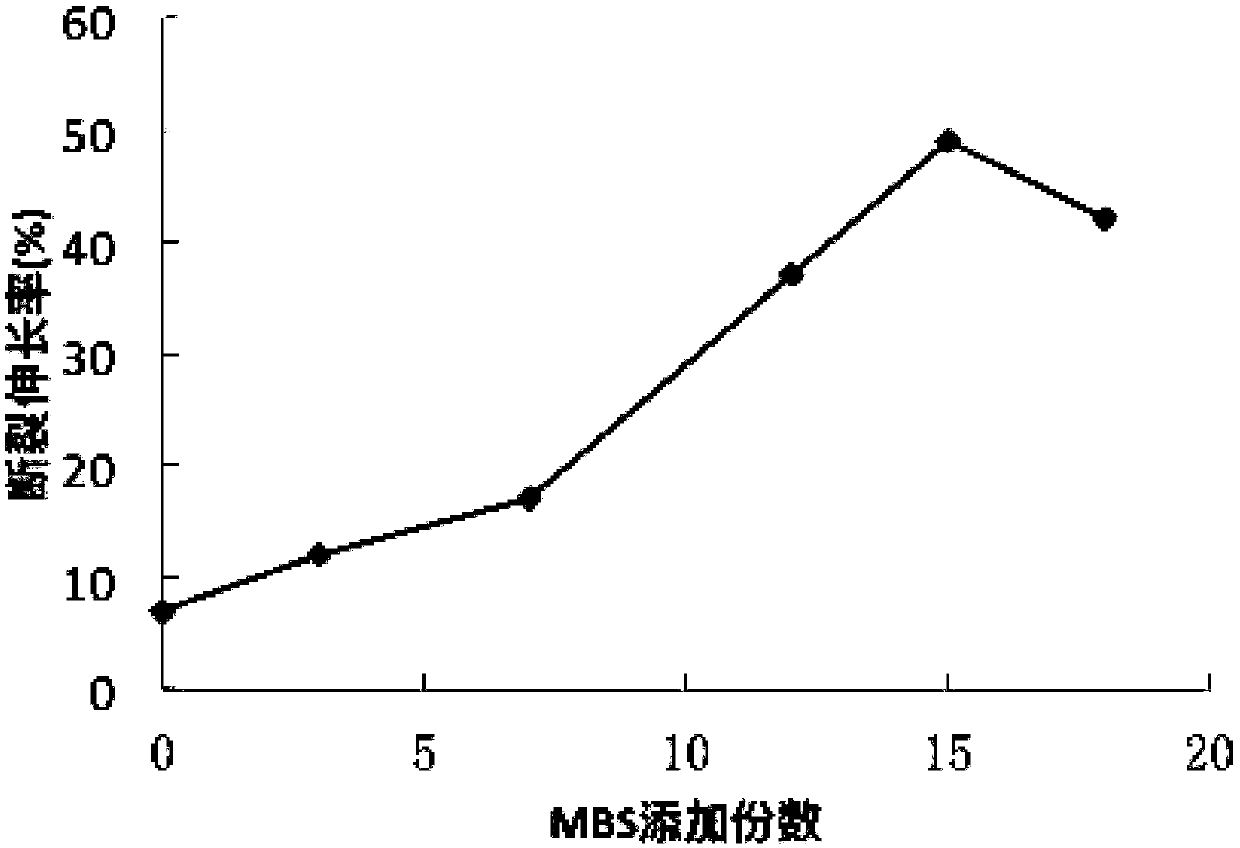

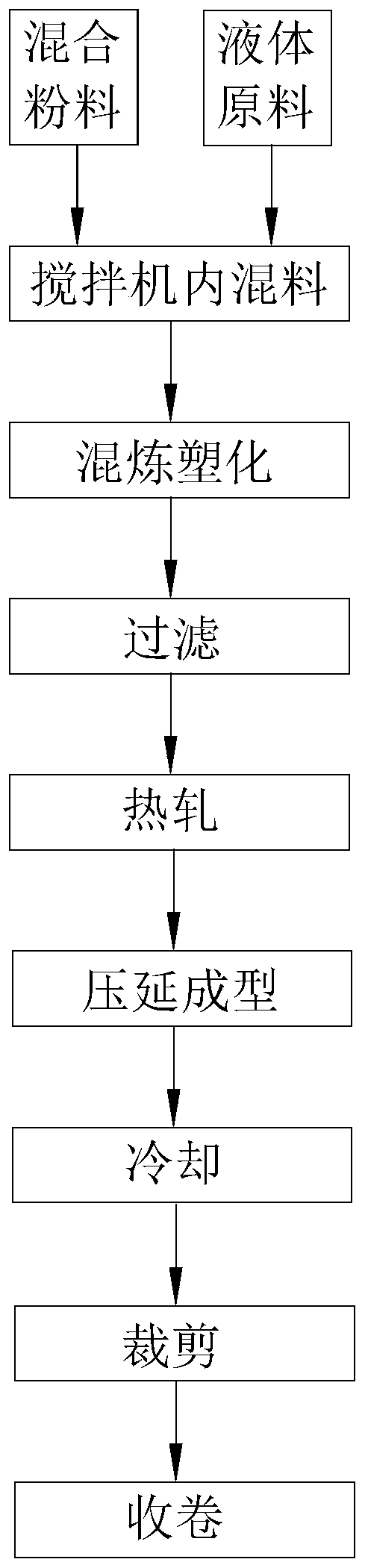

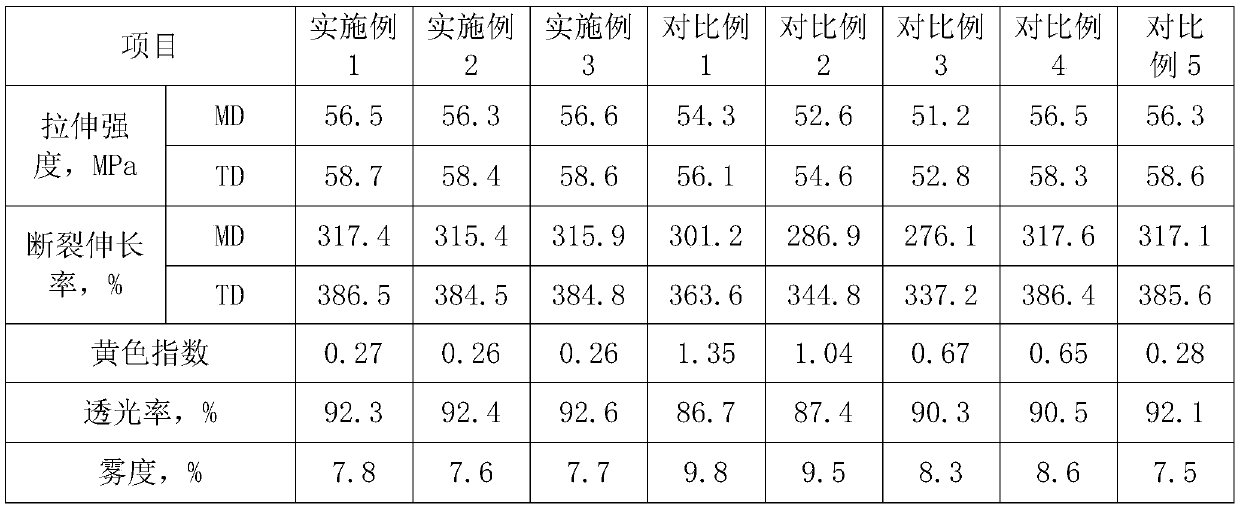

High-strength environment-friendly PVC shrink film and preparation process thereof

The invention discloses a high-strength environment-friendly PVC shrink film and a preparation process thereof. The PVC shrink film is prepared from the following raw materials in parts by weight: 88-100 parts of polyvinyl chloride, 6-10 parts of ethylaniline, 10-15 parts of dioctyl phthalate, 5-10 parts of MBS resin, 1-3 parts of a plasticizer, 2-4 parts of a heat stabilizer, 1-3 parts of an internal lubricant, 1-2 parts of an external lubricant and 3-5 parts of a processing aid. The PVC raw material is modified by virtue of an anti-impact enhancer, the plasticizer, the heat stabilizer, the internal lubricant, the external lubricant and the like through a polymer blending modification technique, and after being mechanically mixed with PVC, a modifier is well dispersed in a PVC matrix, sothat the heat stability of PVC is improved, the processing performance is improved, and meanwhile, the tenacity and impact resistance of PVC can be substantially improved.

Owner:厦门市瀚邦包装制品有限公司

Novel wide-angle lens of endoscope

Disclosed is a novel wide-angle lens for an endoscope, wherein an object lens of the novel wide-angle lens includes a combination of a uniform plano-convex lens and a Grin lens, and the view angle of the lens is widened by increasing the difference between refractive indexes of the lens center and the lens periphery. The Grin lens is adopted at the lens center while the uniform plano-convex lens is adopted at the periphery from one to two apertures, the refractive index of the uniform plano-convex lens is smaller than the smallest refractive index of the Grin lens, and the periphery of the lens is manufactured non-transparently, thereby preventing stray light generated by light reflecting on the sides of the lens.

Owner:SHANGHAI PUJI OPTIC TECH

Hologram laminate, hologram copy method, and hologram producing method

InactiveCN101581911AImprove securityAvoid enteringSynthetic resin layered productsPhotomechanical apparatusHolographic recordingProtection layer

The present invention provides a hologram laminate, a hologram copy method and a hologram producing method. The hologram laminate includes a hologram record layer, and a surface protection layer. The hologram record layer is made of a photosensitive material. The surface protection layer is coated on one surface of the hologram record layer. The surface protection layer is made of an energy ray curing resin. The invention has advantages that it is capable of reducing the whole thickness of the hologram laminate, reducing a production cost, removing air from a boundary between a hologram original master and the hologram laminate, improving the safety, etc.

Owner:SONY CORP

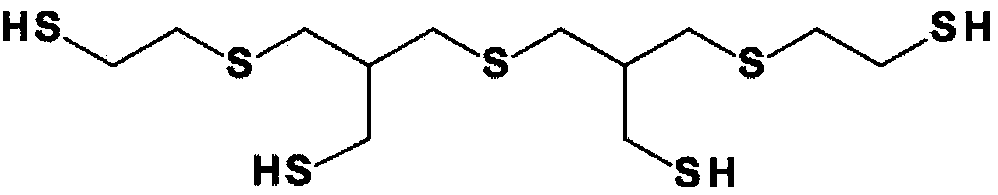

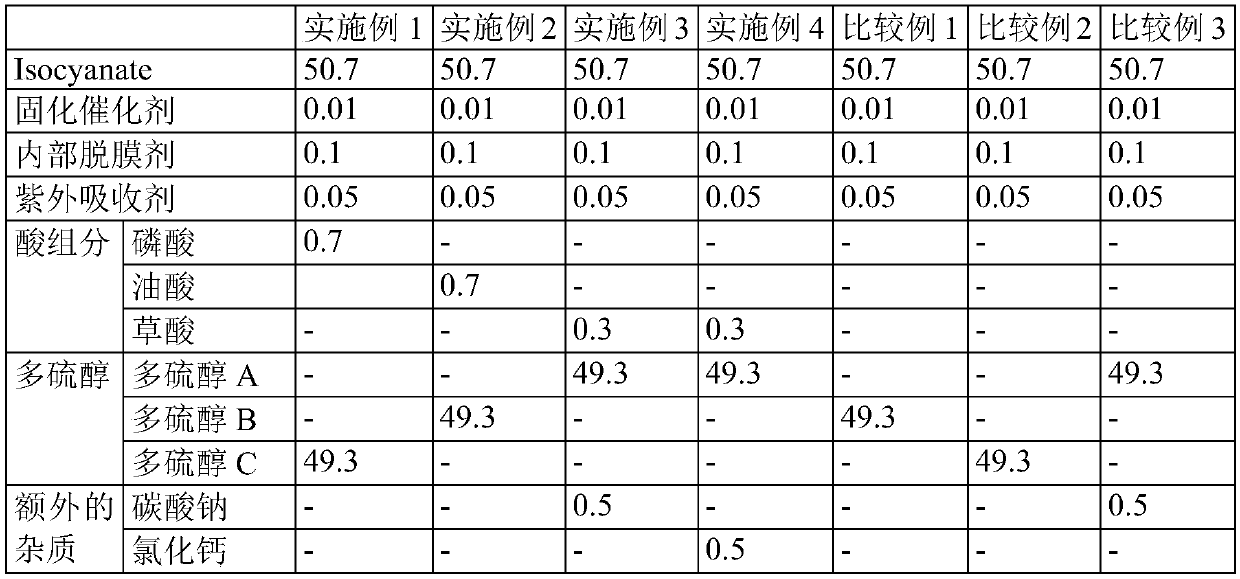

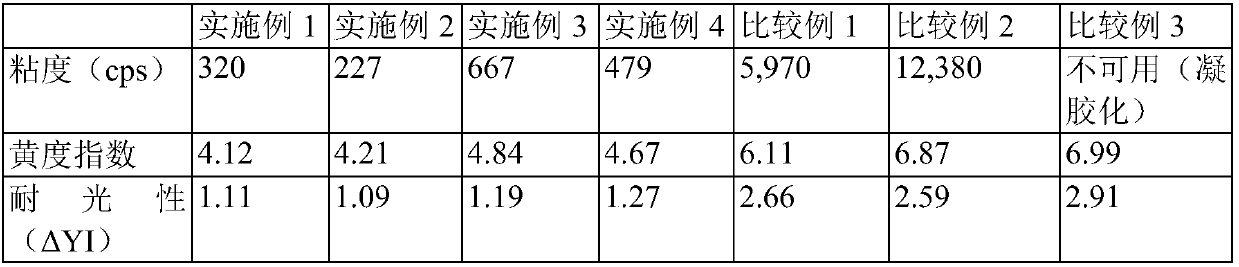

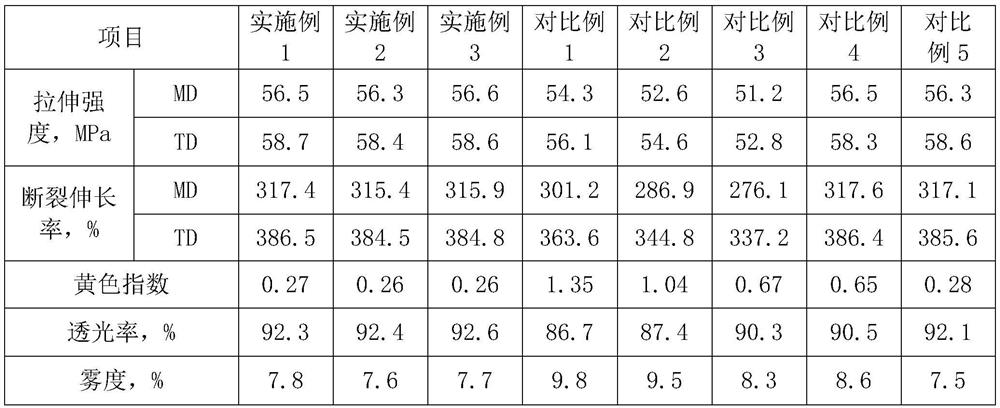

Polymerizable composition for polythiourethane-based optical material

ActiveCN109563229ALow yellowness indexQuality improvementOrganic chemistryOptical partsCamera lensEyeglass lenses

Owner:SKC CO LTD

Transparentizing reagent and application thereof in biological tissue material optical imaging as well as living body skin tissue transparentizing imaging method

ActiveCN110596096AReduce scatterUniform refractive index distributionPreparing sample for investigationTransmissivity measurementsPhosphateTissue expansion

The invention discloses a transparentizing reagent and application thereof in biological tissue material optical imaging as well as a living body skin tissue transparentizing imaging method. The transparentizing reagent is mannose or a mixture formed by dissoving mannose and 1,3-dimethyl-2-imidazolinone in a solvent. The transparentizing reagent can be applied to the biological tissue material optical imaging. The living body skin tissue transparentizing imaging method comprises the following steps: removing hairs on the surface, cleaning and drying; fixing and placing a skin tissue on a focalplane of an optical imaging system; dropwise adding the transparentizing reagent to the skin tissue at an imaging position, and standing for 5-30 minutes; imaging; and after the imaging is finished,wiping the transparentizing reagent, and repeatedly scrubbing and cleaning the surface of the skin tissue with normal saline or phosphate buffer solution, so that the skin tissue restores the originalstate. The reagent disclosed by the invention can not produce obvious tissue expansion or tissue shrinkage when in use, a detailed structure of a biological material can be completely stored, transparentizing time is short, transparentizing capability is high, and the reagent can be applied to the biological tissue material optical imaging.

Owner:SHENZHEN TECH UNIV

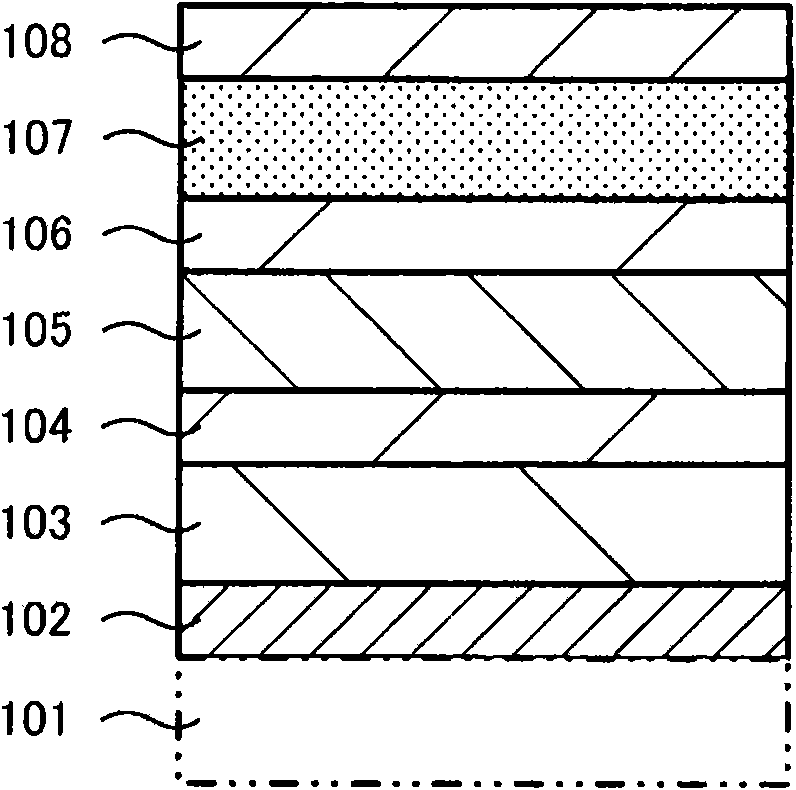

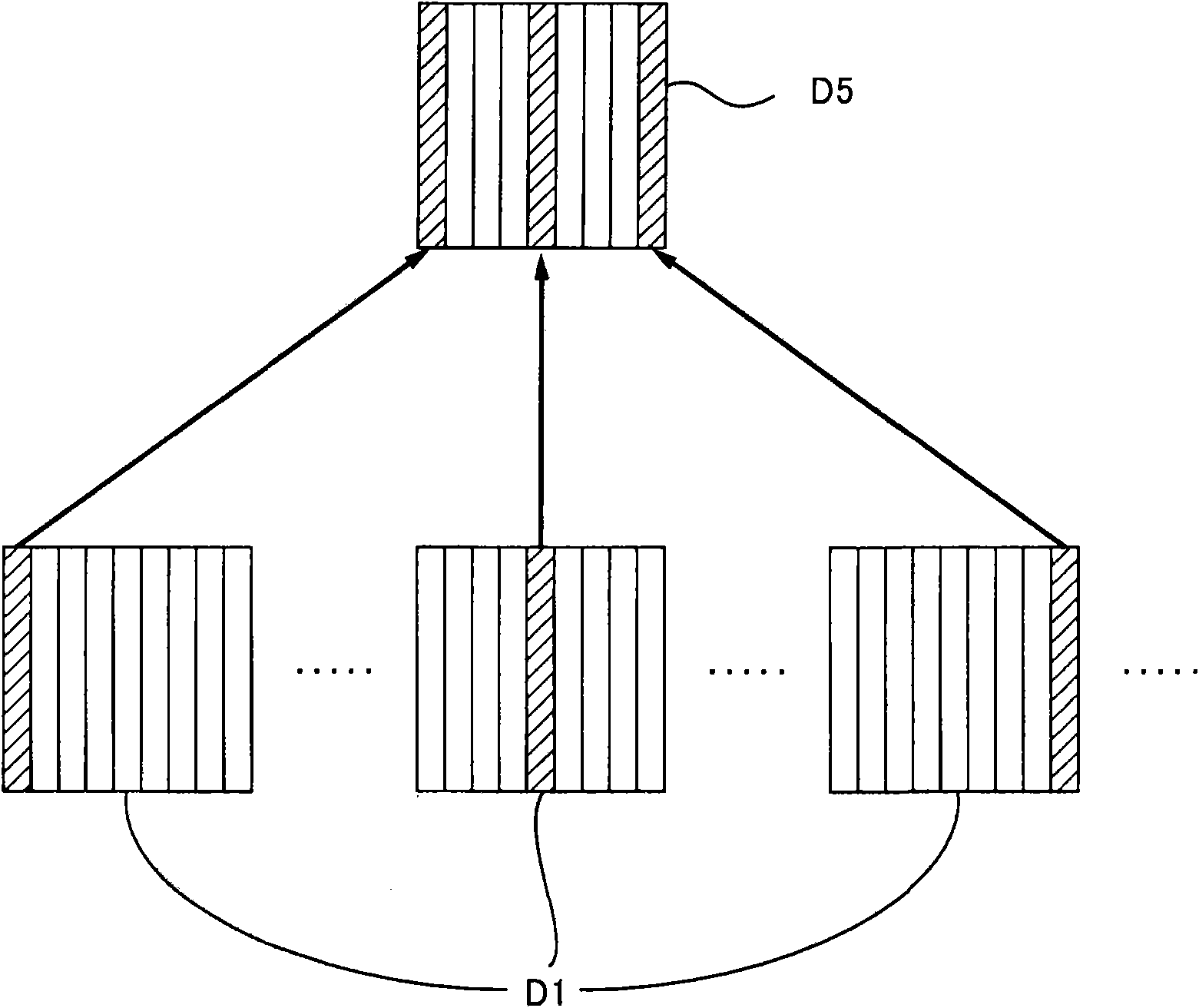

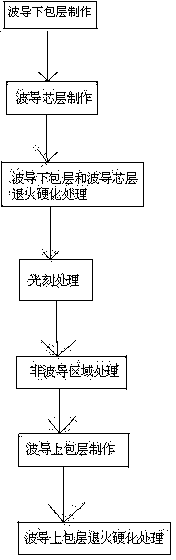

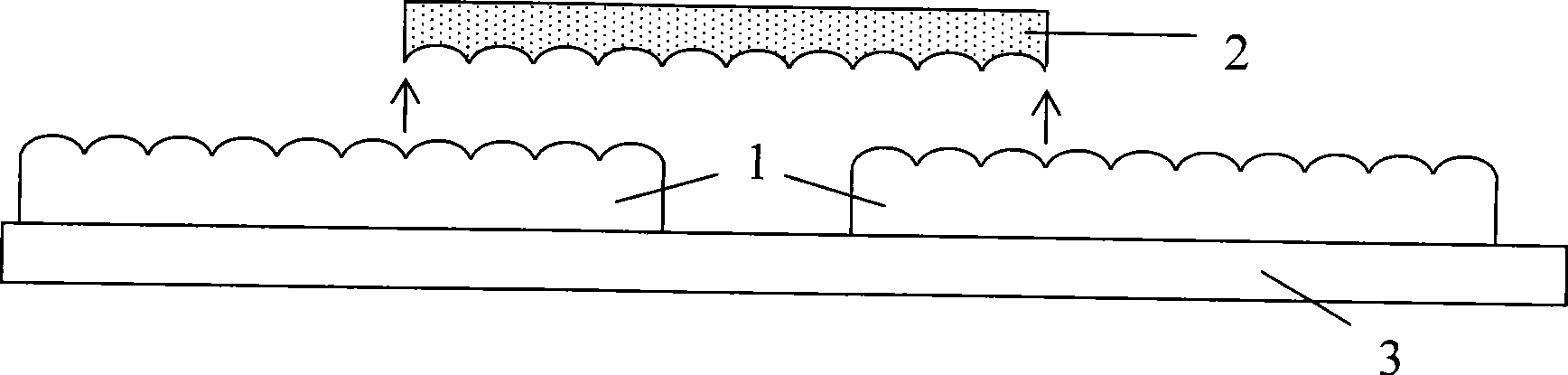

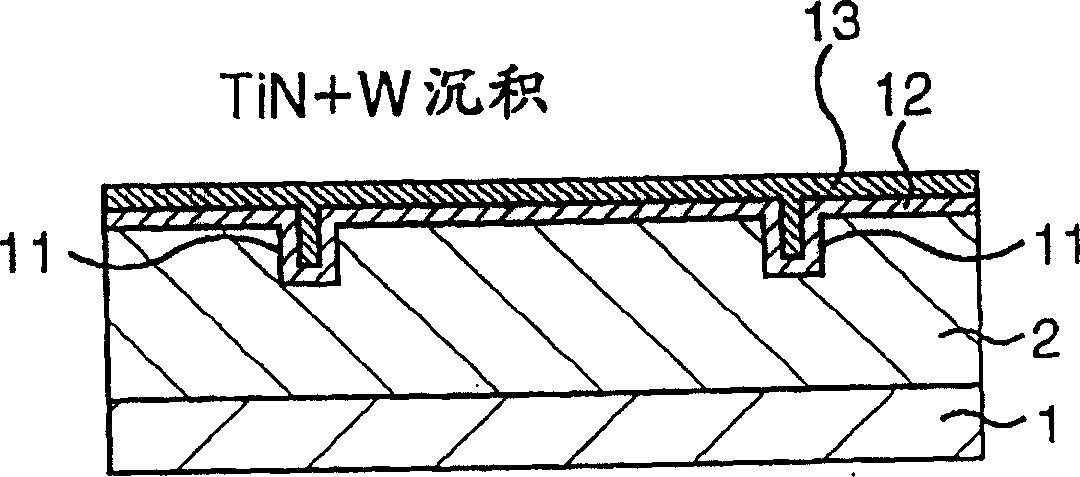

Silicon-dioxide optical waveguide production process for manufacturing optical divider

InactiveCN104360441AUniform refractive indexReduce internal residual stressOptical waveguide light guideGas phaseThermal stability

The invention discloses a silicon-dioxide optical waveguide production process for manufacturing an optical divider. The silicon-dioxide optical waveguide production process includes a lower waveguide wrapping layer manufacturing step, a waveguide core layer manufacturing step, a lower waveguide wrapping layer and waveguide core layer annealing and hardening step, a photoetching step, a non-waveguide area treatment step, an upper waveguide wrapping layer manufacturing step and an upper waveguide wrapping layer annealing and hardening processing step. The lower waveguide wrapping layer manufacturing step includes growing a SiO2 layer on a silicon wafer by the flame hydrolysis method or the chemical vapor deposition process, and doping phosphorous and boron ions as a lower waveguide wrapping layer. The waveguide core layer manufacturing step includes growing another SiO2 layer on the lower wrapping layer as a waveguide core layer by the flame hydrolysis method or the chemical vapor deposition process. The lower waveguide wrapping layer and waveguide core layer annealing and hardening step includes adopting annealing and hardening to let the two SiO2 layers be compact and uniform; the photoetching step includes protecting required waveguide graphs with photoresist. The non-waveguide area processing step includes etching a non-waveguide area by the reactive ion etching process. The upper waveguide wrapping layer manufacturing step includes removing the photoresist, covering another SiO2 layer on the waveguide core layer again by the flame hydrolysis method or the chemical vapor deposition process and doping the boron and phosphorous ions as an upper waveguide wrapping layer. The upper waveguide wrapping layer annealing and hardening step is used for fining and compacting the SiO2 layer of the upper waveguide wrapping layer. According to the above theory, the optical divider manufactured by the silicon dioxide optical waveguide is low internal residual stress, insignificant in birefrigent effect and is good in mechanical performance and thermal stability.

Owner:成都康特电子高新科技有限责任公司

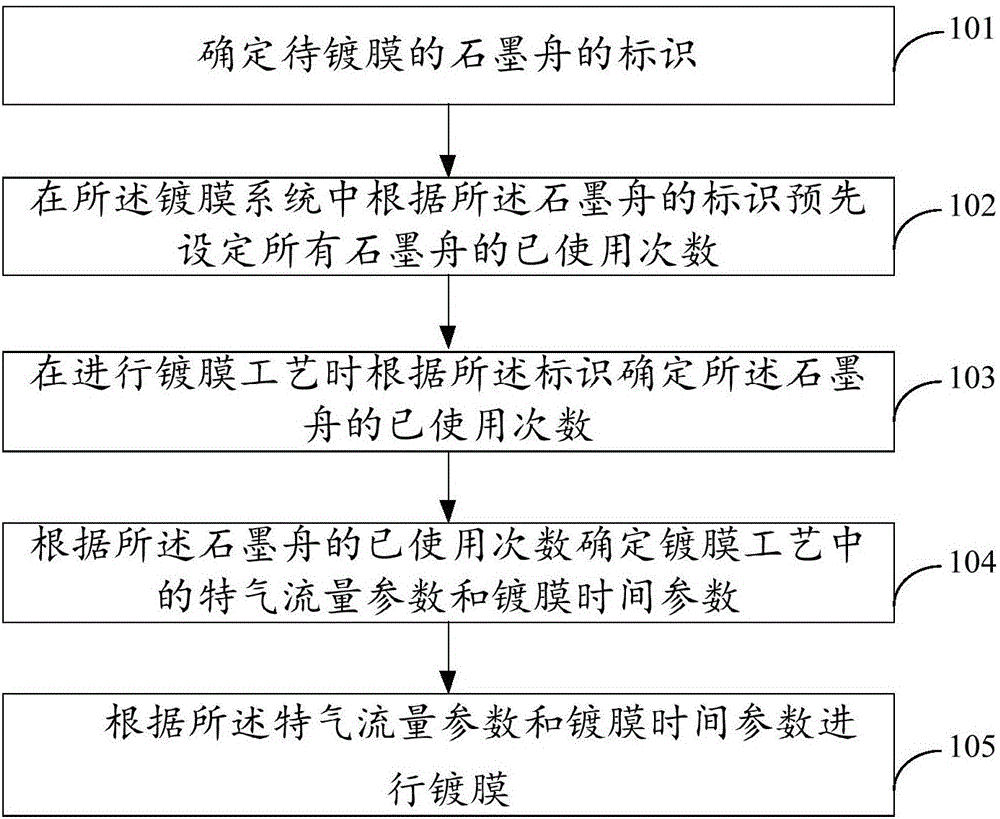

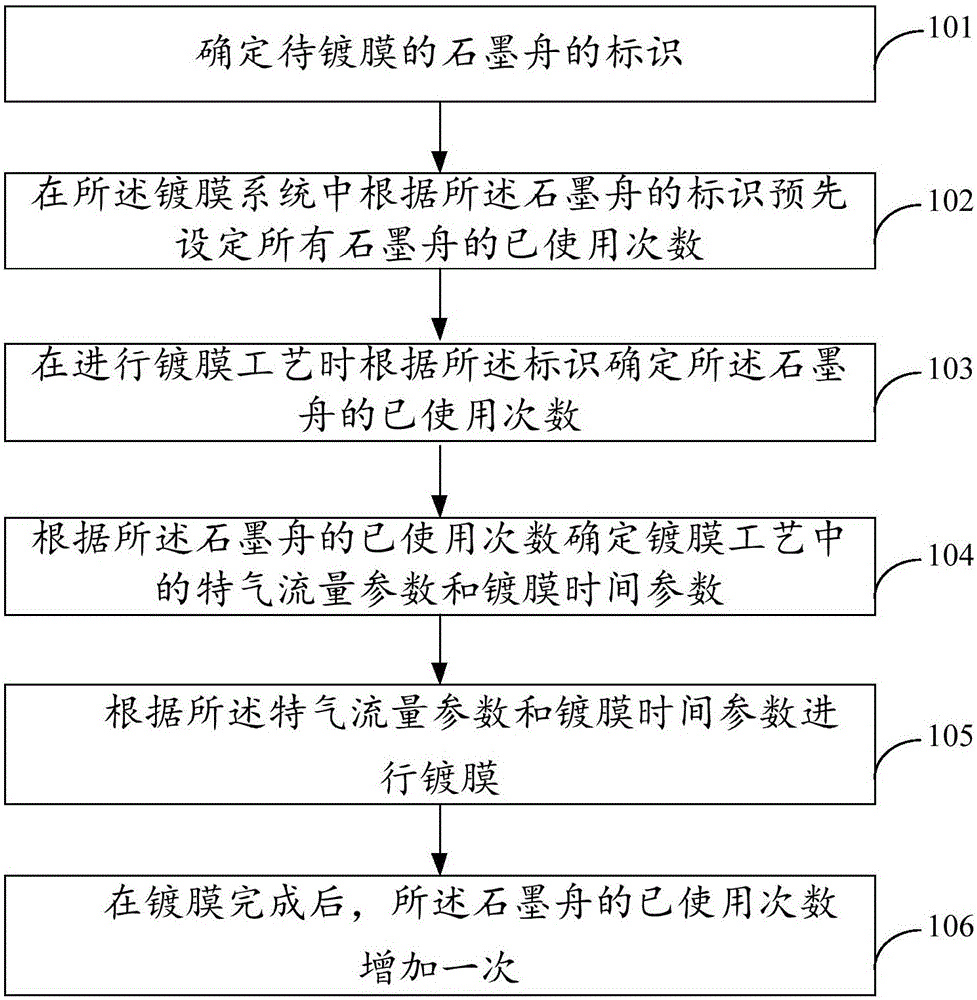

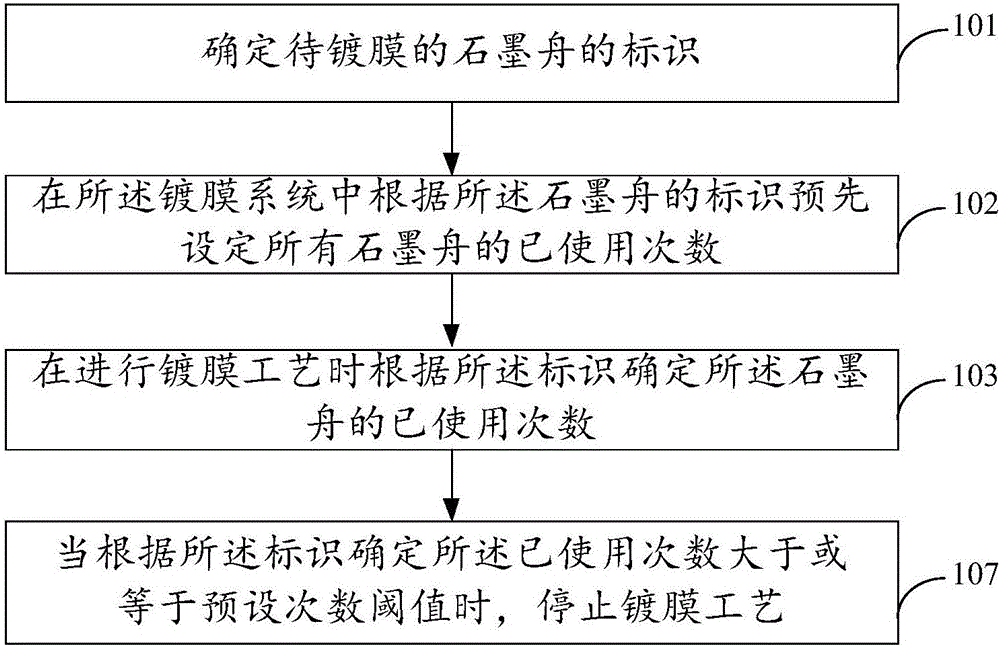

Technological treatment method and device

InactiveCN106245006AWill not affect the coating effectCoating effect is consistentChemical vapor deposition coatingGraphiteSilicon chip

The invention provides a technological treatment method and device applicable to a film plating system using graphite boat for film plating on silicon chips. The method includes: determining the marks of graphite boats needing film plating; in the film plating system, presetting the used number of times of all graphite boats according to the marks of the graphite boats; determining the used number of times of the graphite boats according to the marks; determining the special gas flow parameters and film plating time parameters in the film plating process according to the used number of times of the graphite boats; and conducting film plating according to the special gas flow parameters and film plating time parameters. When the graphite boats are employed to perform film plating operation on silicon chips, the special gas flow parameters and film plating time parameters can be determined according to the used number of times of the graphite boats, the graphite boats with different used numbers of times adopt different special gas flows and film plating time. Even if the surface smoothness of graphite boat sheets in the graphite boats is reduced, the film plating effect of the silicon chips is not affected, the film formed on the silicon chip has consistent thickness and consistent refractivity, and the silicon chip film coating effect is more unified.

Owner:JIANGXI RISUN SOLAR ENERGY CO LTD

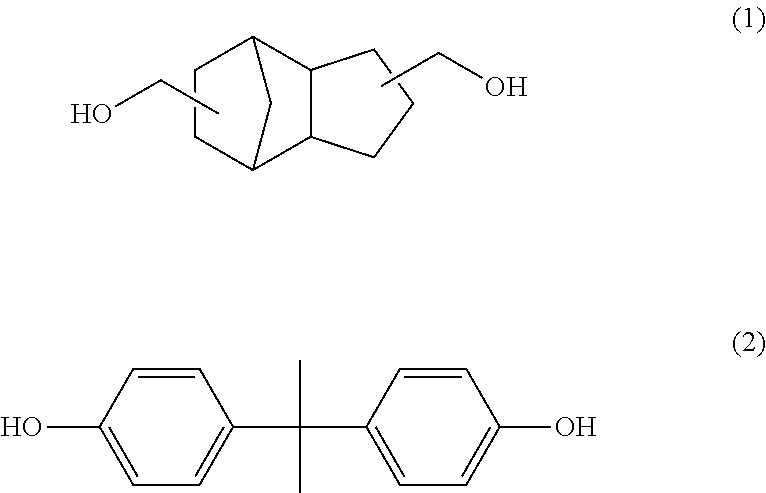

Polycarbonate resin composition

ActiveUS20120220737A1High strengthExcellent hue and stainabilityOptical elementsPolycarbonatePolymer chemistry

To provide a polycarbonate resin composition having a high Abbe's number, high strength and excellent stainability.Disclosed is a polycarbonate resin composition prepared by blendinga polycarbonate resin (A) prepared by forming carbonate bonds in tricyclo[5.2.1.02,6]decanedimethanol with a diester or phosgene, and a weight-averaged molecular weight (Mw) of the polycarbonate resin (A) being equal to or more than 25,000, anda polycarbonate resin (B) prepared by reacting 2,2-bis(4-hydroxyphenyl)propane and phosgene, and weight-averaged molecular weight (Mw) of the polycarbonate resin (B) being equal to or more than 30,000, whereina ratio thereof, 100×(A) / ((A)+(B)), is from 1 to 99% by weight.

Owner:MITSUBISHI GAS CHEM CO INC

PVC film for lamp box cloth and preparation method thereof

InactiveCN111138779AImprove performanceHigh impact strengthFlat articlesPolymer scienceWhitening Agents

The invention relates to a PVC film for lamp box cloth and a preparation method of the PVC film and relates to the technical field of lamp box cloth. The PVC film comprises the following raw materials, by mass, 55-65 parts of PVC resin, 10-15 parts of a methyl methacrylate-butadiene-styrene terpolymer , 5-10 parts of chlorinated polyethylene, 15-20 parts of plasticizer, 2.5-3.5 parts of a stabilizer, 70-75 parts of heavy calcium carbonate, 1-3 parts of bentonite, 3.8-4.5 parts of anatase titanium dioxide, 0.01-0.05 part of a fluorescent whitening agent, 0.2-0.6 part of an ultraviolet light absorber, 0.1-0.5 part of a flame retardant, 0.1-0.3 part of a lubricant and 0.005-0.01 part of a pigment. By improving the thermal stability of the PVC film, the use stability of the lamp box cloth is improved, and the use time of the lamp box cloth is prolonged.

Owner:上海蓝泉塑料制品有限公司

Method of making inorganic, metal oxide spheres using microstructured molds

InactiveCN101506111AGranular adjustmentIncrease profitGlass shaping apparatusThin material handlingMicroparticleMaterials science

A process for making inorganic, metal oxide spheres that includes exposing solidified, molded microparticles that include a glass precursor composition to a temperature sufficient to transform the molded microparticles into molten glass and cooling the molten glass to form inorganic, metal oxide spheres.

Owner:3M INNOVATIVE PROPERTIES CO

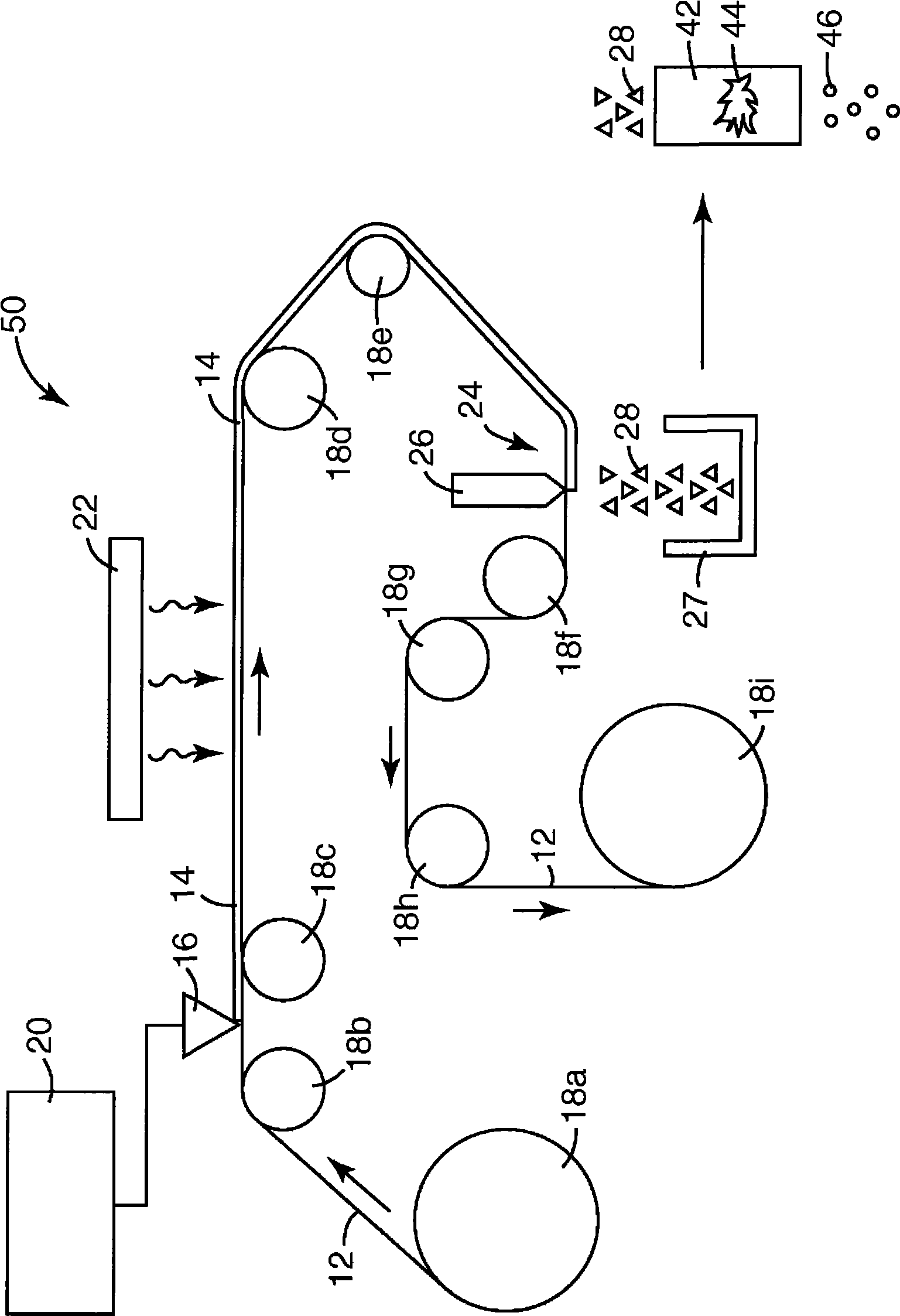

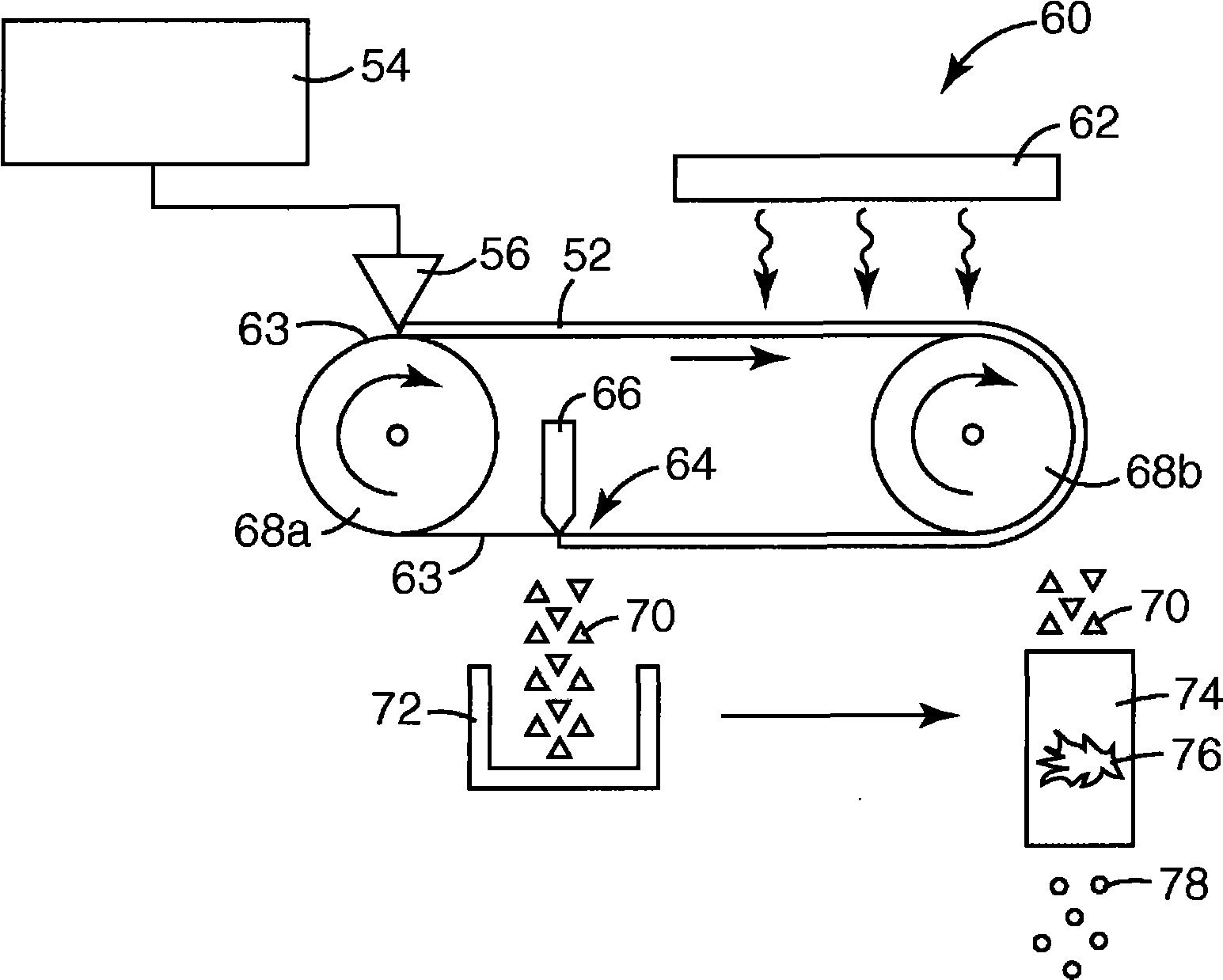

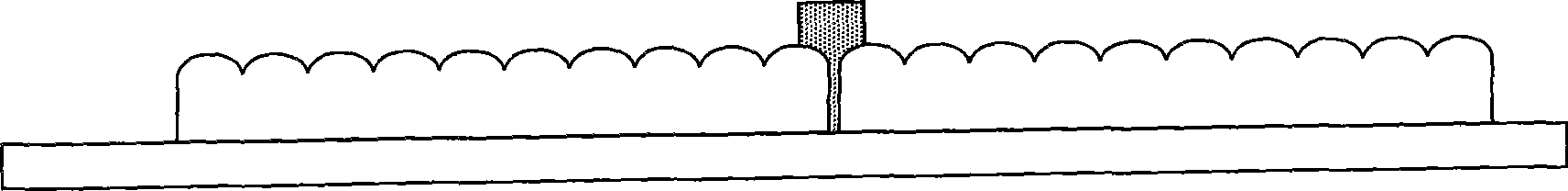

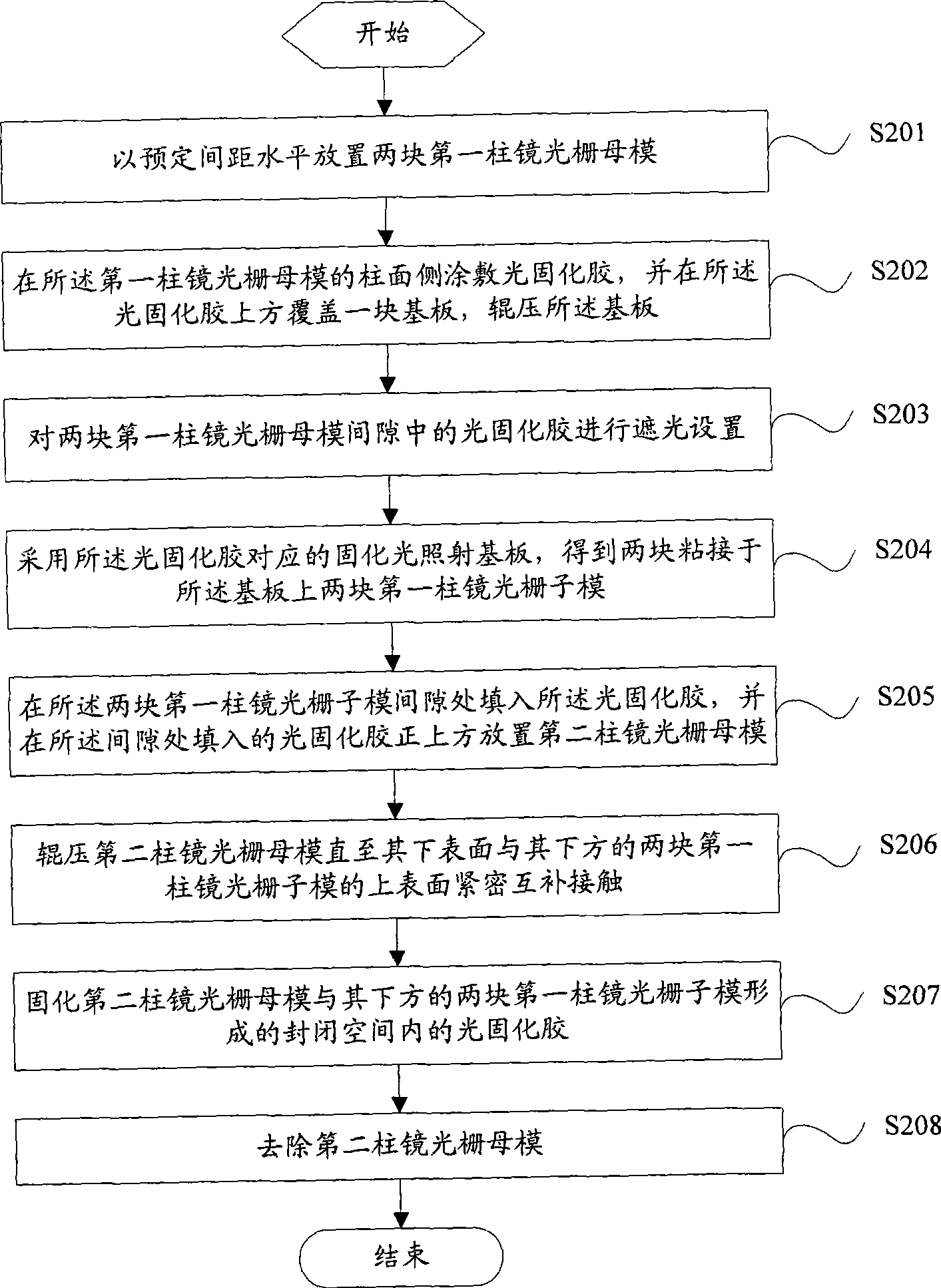

Method for making large size column mirror grating

ActiveCN101419300AImprove surface accuracyUniform refractive indexDiffraction gratingsGratingAdhesive

The invention discloses a method for manufacturing a large-size cylindrical lens grating, which comprises the following steps: step one, at least one first cylindrical lens grating sub mold is generated on a substrate through at least one cylindrical lens grating case mold and light-curing adhesive; and step two, when the number of the first cylindrical lens sub molds generated on the substrate in the step one is one, the same light-curing adhesive is adopted, and a cylindrical lens grating with the same specification as the first cylindrical lens grating case mold is used as a case mold for widening the first cylindrical lens grating sub mold; and when the number of the first cylindrical lens grating sub molds generated on the substrate in the step one is two, the same light-curing adhesive is used to fill the clearance between every two first cylindrical lens gratings, and the first cylindrical lens grating case mold is used as the case mold so as to shape and cure light-curing adhesive at the clearance position between every two first cylindrical lens grating sub molds and make every two first cylindrical lens grating sub molds connected. The method has the advantages of simple operation, wide selective range of refractive index of manufactured cylindrical lens grating, high surface precision of the produced cylindrical lens grating, and good uniformity.

Owner:SUPERD CO LTD

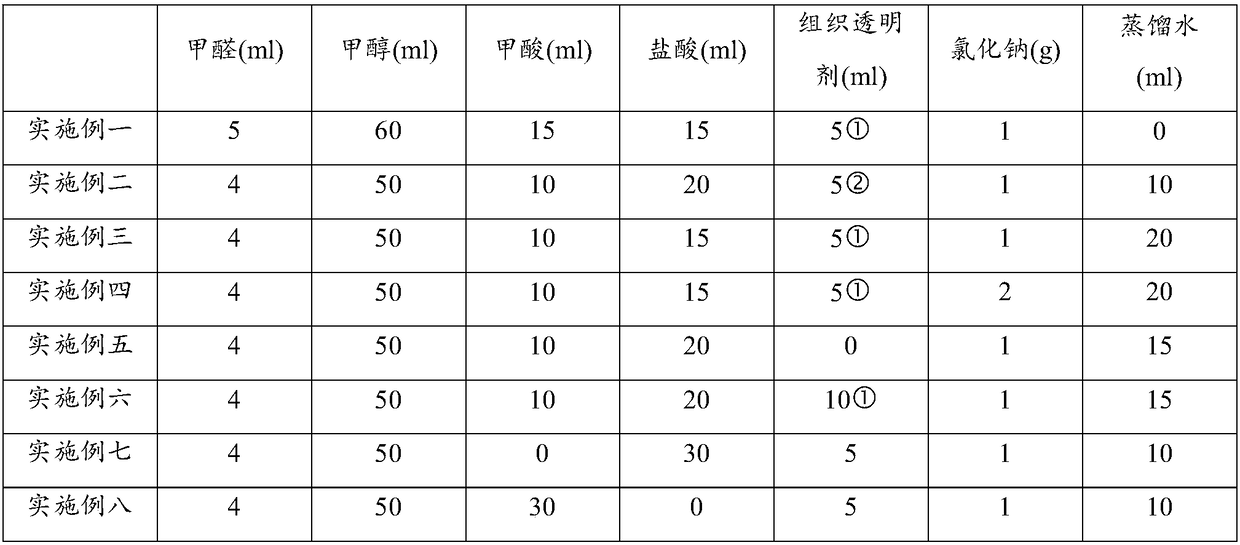

Fish tissue pathological slice decalcifying fluid

ActiveCN108414308AGood decalcification effectSmall molecular weightPreparing sample for investigationChemistryDodecylsulfonic acid

The invention discloses a fish tissue pathological slice decalcifying fluid, which comprises following components: formaldehyde (4-5 v / v%), methanol (50-60 v / v%), formic acid (10-15 v / v%), hydrochloric acid (15-20 v / v%), a tissue clearing reagent (5-6 v / v%), sodium chloride (1-2 v / v%), and the balance being distilled water; wherein the tissue clearing agent comprises following components: 50 to 55vol.% of dimethyl sulfoxide, 15 to 20 mass% of fructose, 1 to 2 mass% of sodium bicarbonate, 10 to 15 mass% of sodium dodecyl sulfonate, and the balance being water. The provided decalcifying fluid can solve the technical problems that in the prior art, the decalcification time is long and the transparency is bad.

Owner:SICHUAN AGRI UNIV

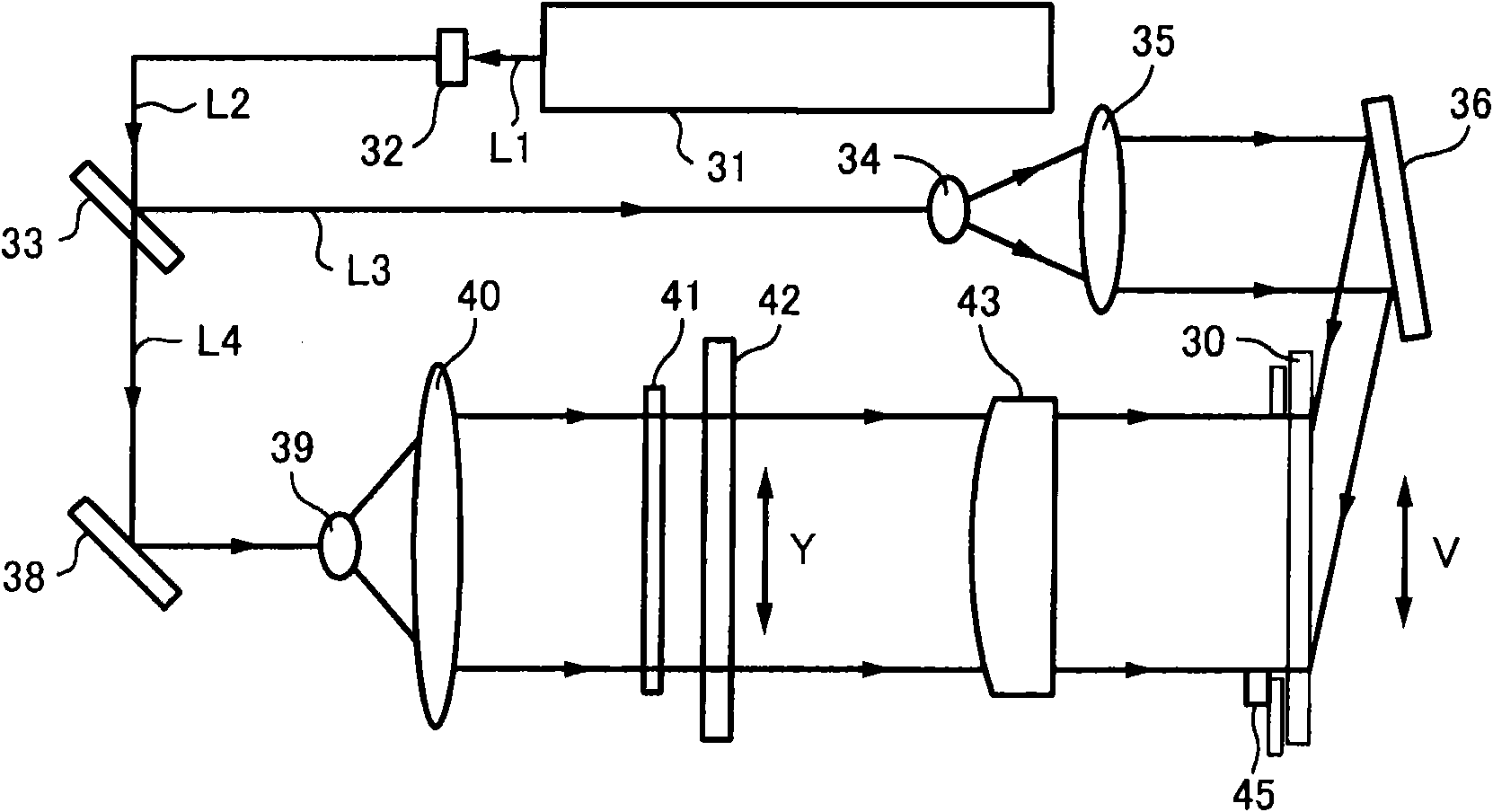

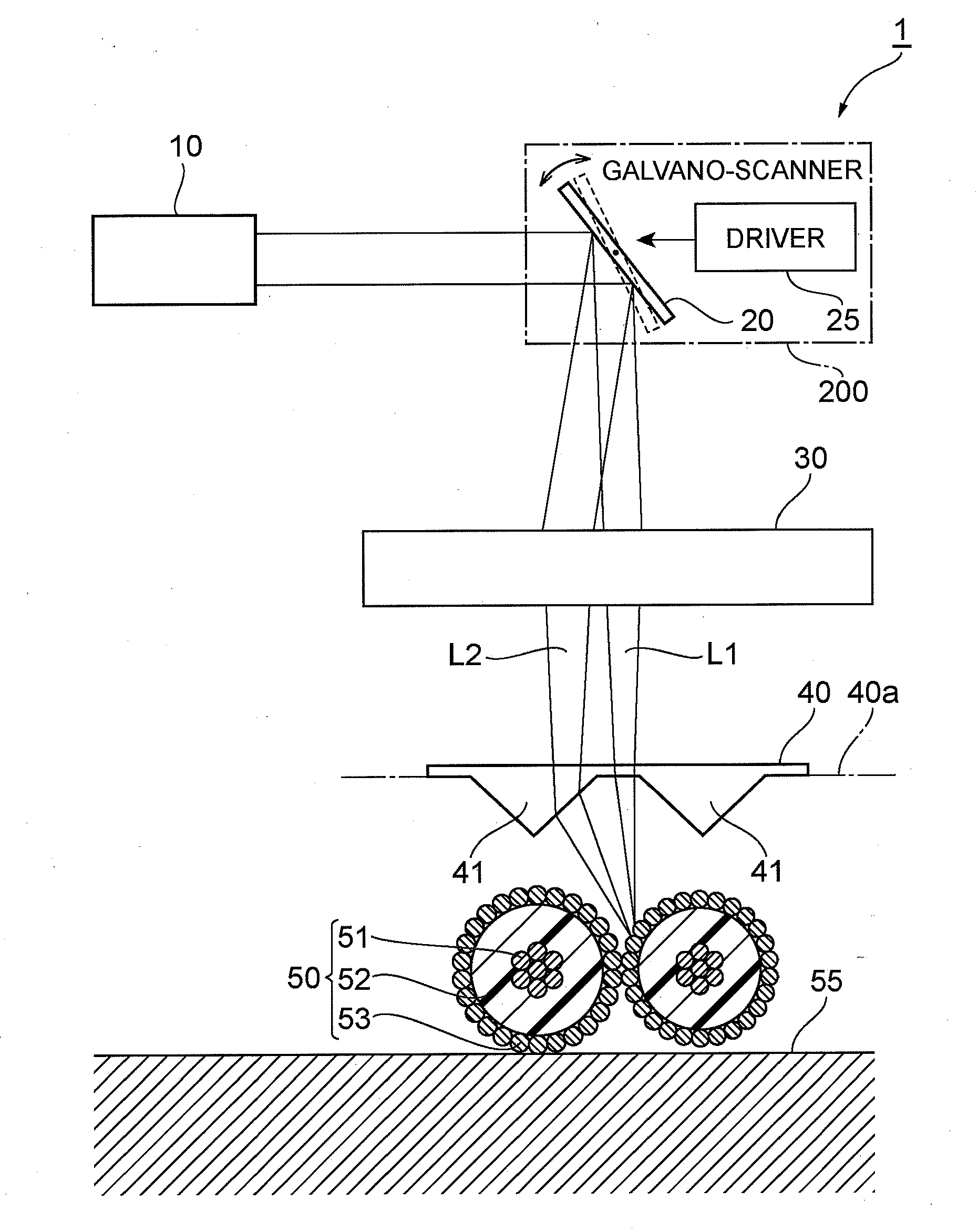

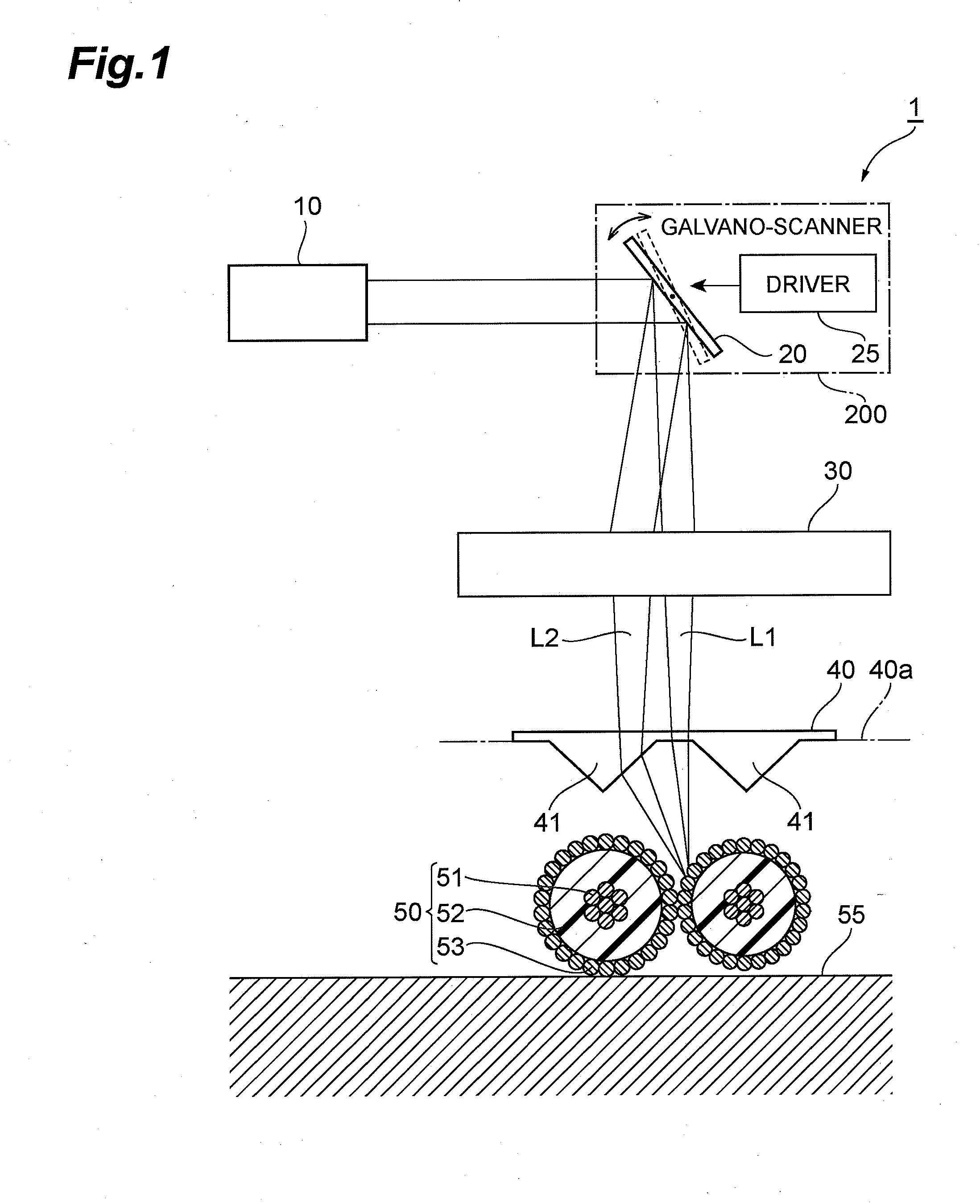

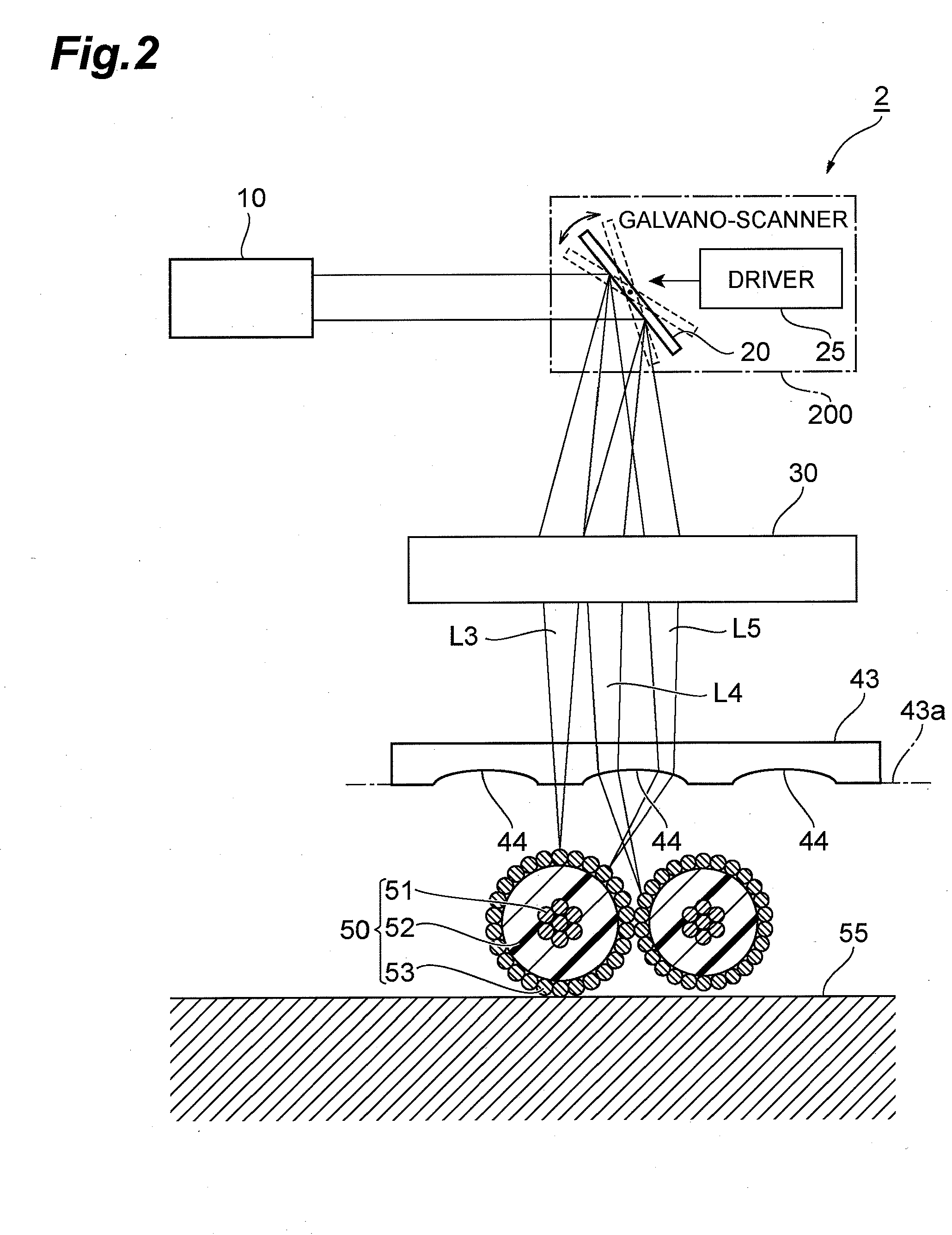

Laser processing apparatus and laser processing method

InactiveUS20090277885A1Efficient processingEfficient ConcentrationPrismsWelding/soldering/cutting articlesCamera lensLaser processing

The present invention relates to a laser processing apparatus having a structure for effectively processing of objects by condensing a laser beam, and a laser processing method. A laser processing apparatus comprises a common mount surface on which plural objects are disposed in an array, a light source, a lens the reflection direction of which is changeable, and a condensing direction modifier. A laser beam from the light source arrives at the lens through a galvano-mirror. Herein, the galvano-mirror is arranged such that the reflection position thereof agrees with the front focal position of the lens. As the galvano-mirror reflects a laser beam toward the lens while the reflection direction is changed, the arriving position of the laser beam is scanned on the entrance surface of the lens. The condensing direction modifier modifies, according to the irradiation position of the laser beam arrived from the lens, an exit direction of the laser beam.

Owner:SUMITOMO ELECTRIC IND LTD

Optical waveguide and the method of fabricating the same

InactiveUS7521725B2Uniform refractive indexAvoid enteringSolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsWaveguide

Disclosed herein is an optical waveguide comprising a core layer to be an optical waveguide region, an upper clad layer covering the core layer and a lower clad layer, characterized in that an ultraviolet control region for preventing ultraviolet light from entering is provided at any one location of under the lower clad layer, on an interface of the lower clad layer and the upper clad layer, and on the upper clad layer. And a method of fabricating this optical waveguide is also disclosed.

Owner:SANYO ELECTRIC CO LTD

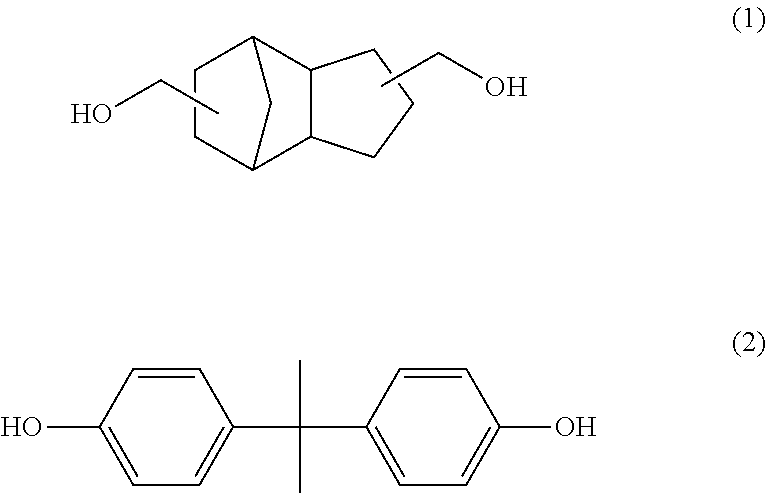

Polycarbonate resin composition

To provide a polycarbonate resin composition having a high Abbe's number, high strength and excellent stainability.Disclosed is a polycarbonate resin composition prepared by blendinga polycarbonate resin (A) prepared by forming carbonate bonds in tricyclo[5.2.1.02,6]decanedimethanol with a diester or phosgene, and a weight-averaged molecular weight (Mw) of the polycarbonate resin (A) being equal to or more than 25,000, anda polycarbonate resin (B) prepared by reacting 2,2-bis(4-hydroxyphenyl)propane and phosgene, and weight-averaged molecular weight (Mw) of the polycarbonate resin (B) being equal to or more than 30,000, whereina ratio thereof, 100×(A) / ((A)+(B)), is from 1 to 99% by weight.

Owner:MITSUBISHI GAS CHEM CO INC

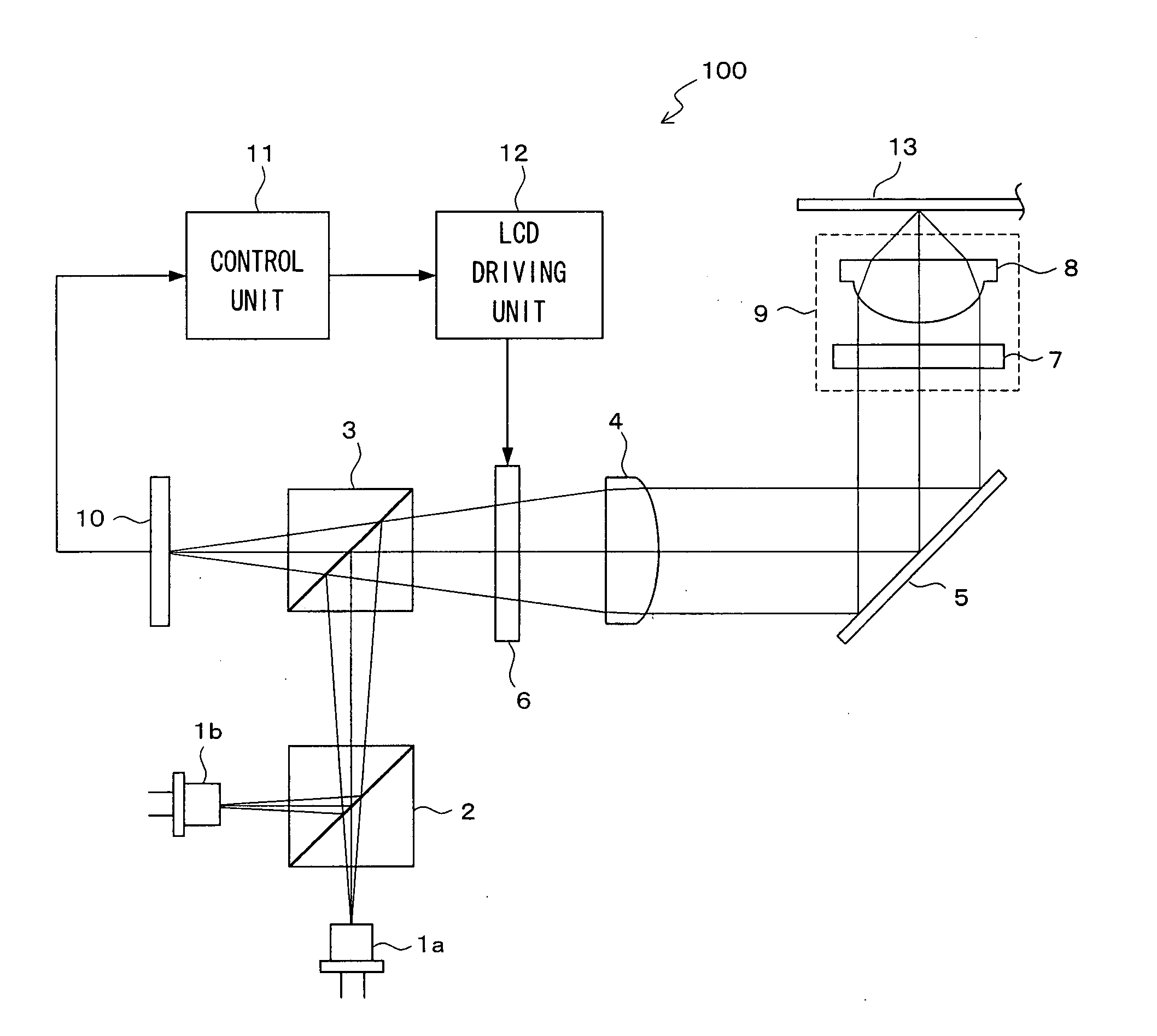

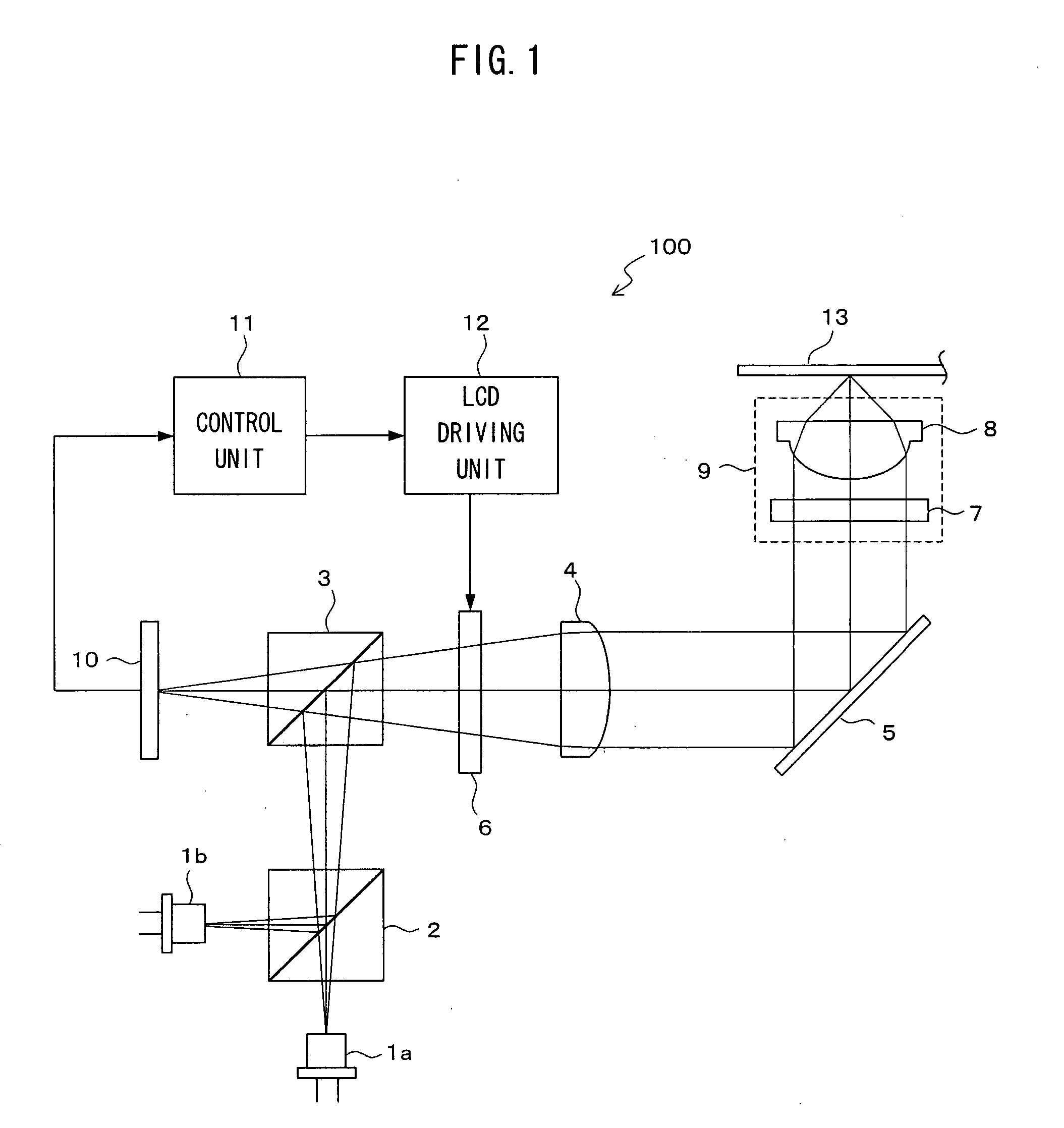

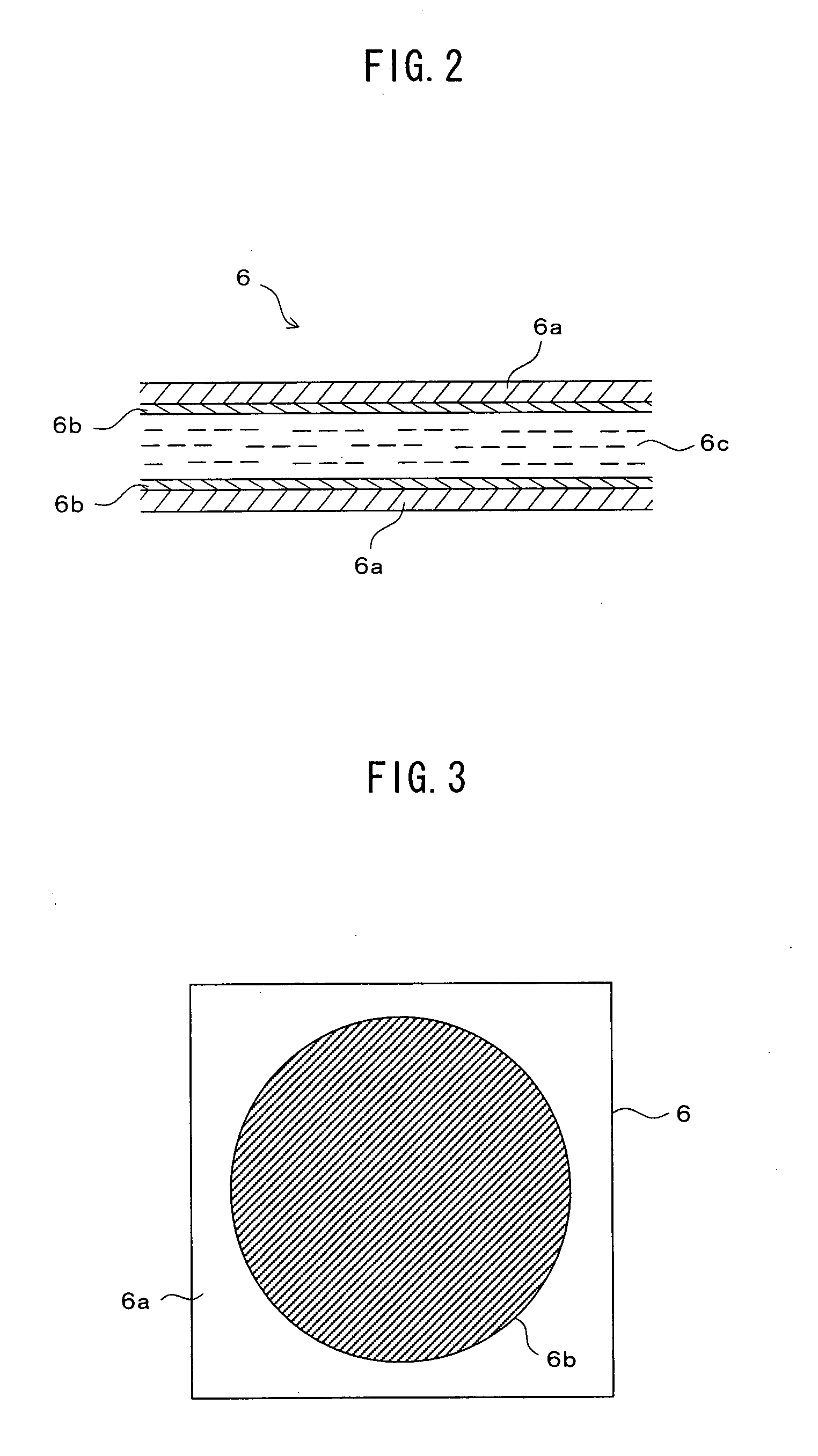

Optical pickup device

InactiveUS20080055602A1Uniform refractive indexCorrected spherical aberrationOptical beam sourcesScattering properties measurementsOptical pickupRefractive index

The present invention provides an optical pickup device in which a liquid crystal device is easily attached, mass productivity is high, a movable actuator is light, excellent response can be obtained and, moreover, the liquid crystal device can be easily controlled. In an optical pickup device in which laser beams emitted from light sources pass through a collimator lens and an objective lens and are condensed to a surface of an optical disc, a liquid crystal device for correcting spherical aberration of an outgoing light from the objective lens is provided in front of the collimator lens when viewed from the light sources. The liquid crystal device has a single electrode formed in a wide range in each of a pair of substrates facing each other while sandwiching liquid crystal. A predetermined voltage is applied to the electrode to uniformly change the refractive index of the whole electrode region in the liquid crystal device and make air conversion length between the light sources and the collimator lens variable, thereby changing the degree of parallelization of outgoing light from the collimator lens and correcting spherical aberration.

Owner:FUNAI ELECTRIC CO LTD

Pvc (polyvinyl chloride) heat-shrinkable film and preparation method thereof

ActiveCN109880253AImprove shielding effectGood visible light transmittancePolymer scienceHexahydrophthalic anhydride

The invention discloses a PVC (polyvinyl chloride) heat-shrinkable film and a preparation method thereof, and belongs to the technical field of polymer packaging materials, the PVC heat-shrinkable film comprises the following components in parts by weight: 90-100 parts of PVC resin, 5-7 parts of a flexibilizer, 3-5 parts of a plasticizer, 1-2 parts of a heat stabilizer, 1-2 parts of a light stabilizer, 1-2 parts of a lubricant and 0.5-1 part of an anti-blocking agent; the light stabilizer is prepared from modified nano titanium dioxide, tetraethyl orthosilicate, zinc stearate, hexahydrophthalic anhydride and polymethyl methacrylate through melting and granulation. According to the invention, through the cooperation of the light stabilizer and the thermal stability, the PVC can be protectedduring the PVC processing process and during long-time illumination, so that yellowing is prevented, and good transparency is kept.

Owner:嘉兴新安包装材料股份有限公司

Optical clearing agent for bone tissue

ActiveCN102749231BUniform refractive indexReduce scatterPreparing sample for investigationIn-vivo testing preparationsSodium bicarbonateSodium Diatrizoate

The present invention discloses an optical clearing agent for bone tissue. The optical clearing agent comprises dimethyl sulfoxide, sodium bicarbonate, and at least two materials selected from polyethylene glycol-400, methyl salicylate, ethylenediaminetetraacetic acid, sodium diatrizoate, glycerol, glucose, sodium dodecylbenzene sulfonate, sorbitol and laurinol, wherein a volume percentage of the dimethyl sulfoxide in the optical clearing agent for bone tissue is 40-80%, a mass percentage of the sodium bicarbonate in the optical clearing agent for bone tissue is 1-2%, the balance is other materials, and the pH value of the optical clearing agent for bone tissue is 6-11. After the optical clearing agent for bone tissue in the present invention acts on bone tissue, a refractive index inside the tissue can be quickly homogenized, and scattering inside the tissue can be reduced, such that the tissue provides improved transparency for light, the imaging depth is increased, and a new method for obtaining cortex neuron subcellular structures and microvascular information is provided. After the optical clearing agent for bone tissue is locally coated on the bone tissues or is adopted to soak the bone tissues, the bone tissue can provide improved transparency for light.

Owner:HUAZHONG UNIV OF SCI & TECH

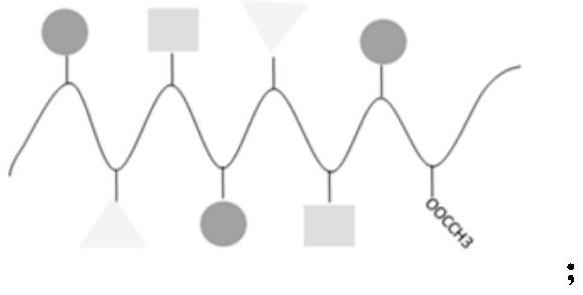

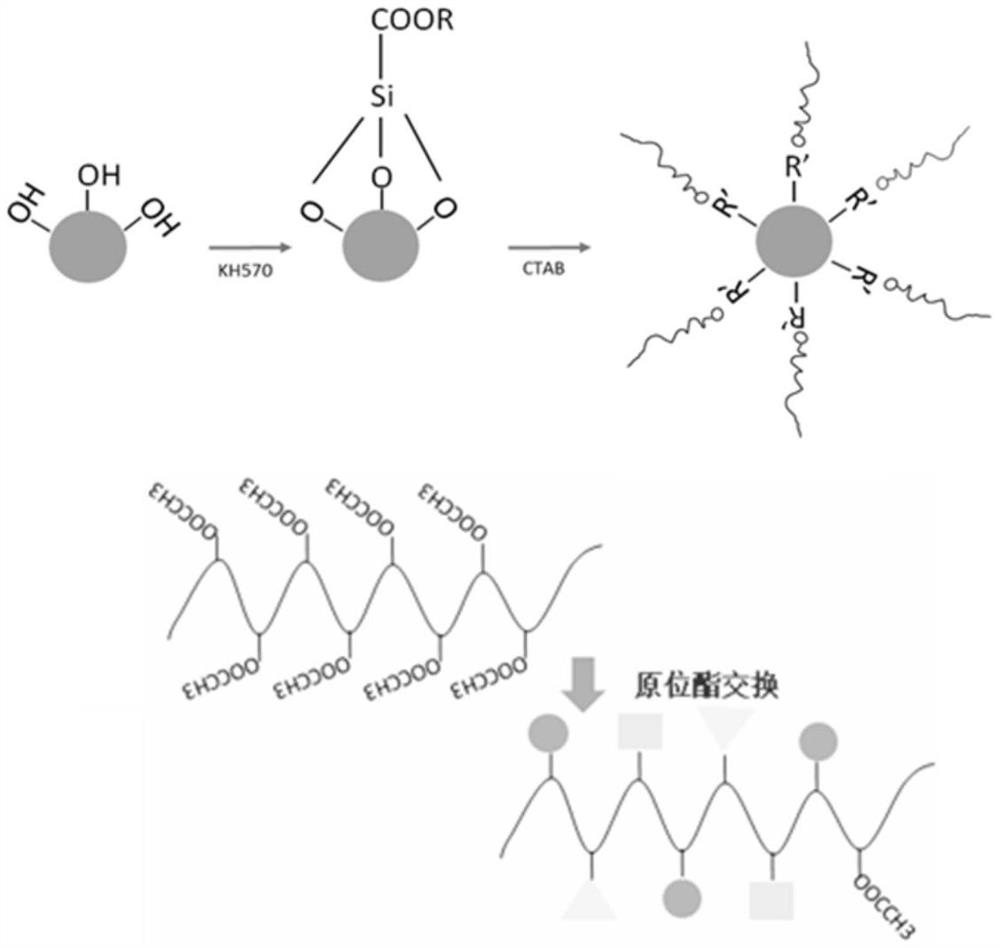

Cesium tungsten system transparent heat insulation master batch and preparation method thereof

The invention discloses a cesium tungsten system transparent heat insulation master batch and a preparation method thereof. The cesium tungsten system transparent heat insulation master batch comprises resin, HALS, modified Cs0. 33WO3 nano slurry, an ultraviolet absorption aid, an antioxidant and a catalyst. The preparation method comprises the following steps: stirring the resin, the HALS, the antioxidant, the ultraviolet absorption aid and the catalyst, adding the modified Cs0. 33WO3 nano slurry, and performing in-situ extrusion ester exchange reaction at 90-110 DEG C to obtain the heat-insulating master batch. According to the heat insulation master batch, the Cs0. 33WO3 nano slurry, the HALS and the resin are subjected to blending extrusion for ester exchange, and the nano metal oxide and the HALS are grafted to a macromolecular chain, so that the nano dispersion is uniform, the refractive index is uniform, the haze is low, and the absorption and anti-aging stability of short-wave blue light are improved.

Owner:南京亚鼎光学有限公司

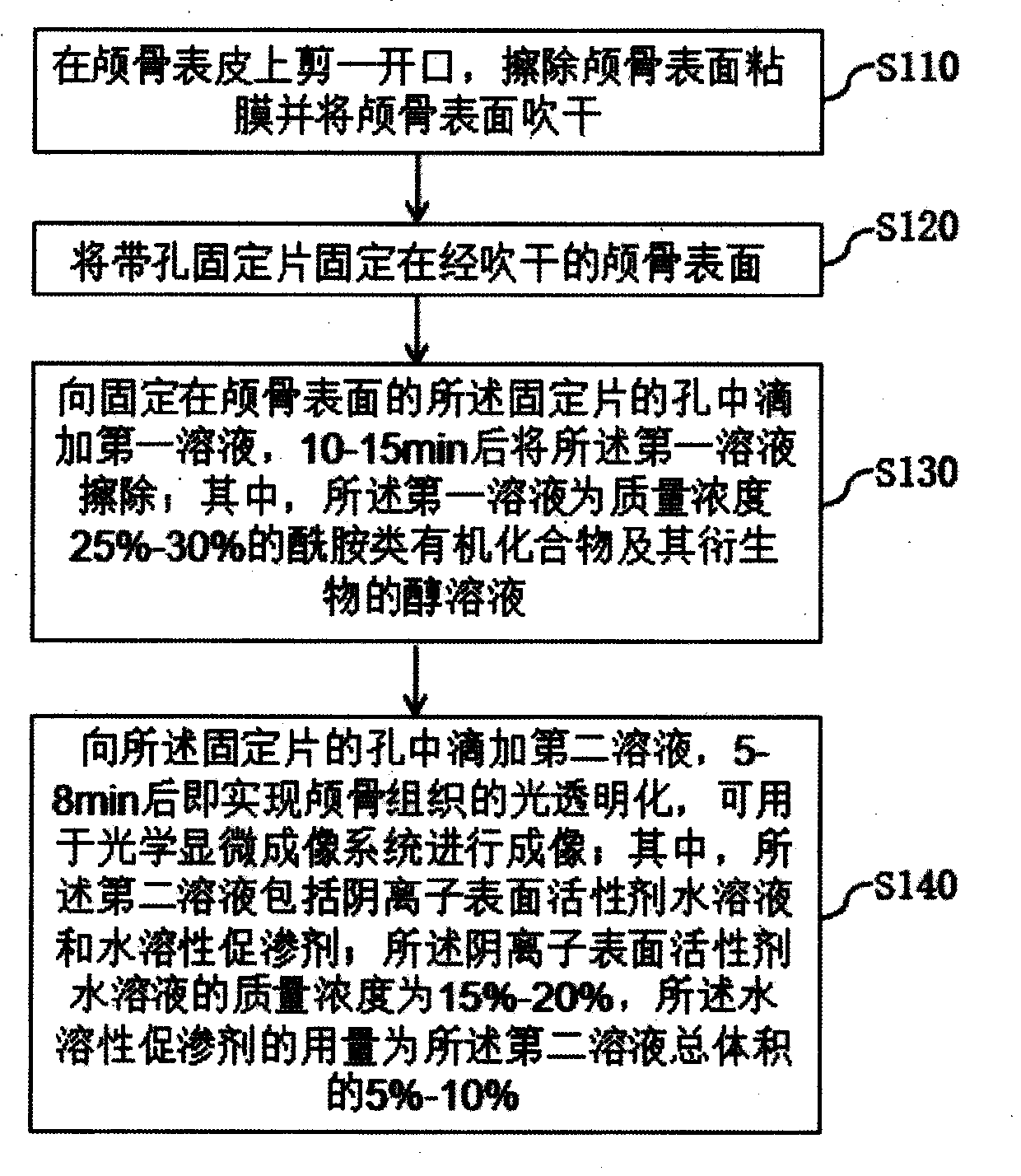

A skull light-transparency reagent and reversible skull tissue light-transparency method

ActiveCN106975083BReduce scatterUniform refractive indexDiagnostics using lightSensorsOptical transparencyOptical clearing

The invention discloses a skull optical clearing reagent and a reversible skull tissue optical clearing method, belonging to the technical field of bioimaging. The optical clearing reagent comprises a first solution and a second solution, wherein the first solution is an alcohol solution having the mass concentration being 25-30 % and composed of an amide organic compound and a derivative of the amide organic compound; the second solution comprises a water solution of an anionic surfactant, and a water-soluble penetration enhancer, the mass concentration of the water solution of the anionic surfactant is 15-20 %, and the use amount of the water-soluble penetration enhancer is 5-10 % of the total volume of the second solution. By dropwise adding the first solution and the second solution on the surface of the skull sequentially, the optical transparency of the skull tissue is realized, and the reagent can be used in an optical microscopic imaging system for imaging. With the reagent and the method, the nondestructive and non-invasive transparent skull window is established, the high-resolution imaging of a cortex microvessel system is realized, the operation is simple, the imaging quality is high, and the repeated imaging for a plurality of times can be realized.

Owner:佳维斯(武汉)生物医药有限公司

Optical switch element and its manufacturing method

InactiveCN1218197CUniform refractive indexSimple and precisely formedSemiconductor/solid-state device manufacturingOptical waveguide light guideGas phaseRefractive index

A lower clad, cores, and an upper clad are formed by a chemical vapor deposition method (CVD method). At least one of the additional amount of oxygen, the additional amount of nitrogen, and the additional amount of silicon of a silicon oxynitride film is adjusted so that the cores have a desired higher refractive index than those of the clads. Further, end point detectors are formed which become etching stoppers of dry etching in pattern forming the cores.

Owner:FUJITSU SEMICON LTD

A kind of PVC heat-shrinkable film and preparation method thereof

ActiveCN109880253BImprove shielding effectGood visible light transmittancePolymer scienceSilicic acid

The invention discloses a PVC (polyvinyl chloride) heat-shrinkable film and a preparation method thereof, and belongs to the technical field of polymer packaging materials, the PVC heat-shrinkable film comprises the following components in parts by weight: 90-100 parts of PVC resin, 5-7 parts of a flexibilizer, 3-5 parts of a plasticizer, 1-2 parts of a heat stabilizer, 1-2 parts of a light stabilizer, 1-2 parts of a lubricant and 0.5-1 part of an anti-blocking agent; the light stabilizer is prepared from modified nano titanium dioxide, tetraethyl orthosilicate, zinc stearate, hexahydrophthalic anhydride and polymethyl methacrylate through melting and granulation. According to the invention, through the cooperation of the light stabilizer and the thermal stability, the PVC can be protectedduring the PVC processing process and during long-time illumination, so that yellowing is prevented, and good transparency is kept.

Owner:嘉兴新安包装材料股份有限公司

Footpad skin tissue optical clearing agent

InactiveCN103263678BReduce scatterUniform refractive indexIn-vivo testing preparationsOptical clearingWhite petrolatum

The invention discloses a footpad skin tissue optical clearing agent, which includes fructose, ethanol, water, and at least three of the following substances: polyethylene glycol-400, sorbitol, glucose, propylene glycol, glycerol, sodium dodecyl benzene sulfonate, dimethyl sulfoxide, butylbenisothiazolene, azone, peppermint oil and petroleum jelly, wherein the mass percentage of fructose in the footpad skin tissue optical clearing agent is 20%-75%, the mass percentage of ethanol in the footpad skin tissue optical clearing agent is 0.8%-1.5%, the mass percentage of water in the footpad skin tissue optical clearing agent is 7%-30%, and the balance of other substances. The present invention acts on the footpad skin tissue, so that the refractive index in the tissue can be quickly uniform, the scattering in the tissue is reduced, the tissue becomes transparent to light, imaging depth is improved, and a new method is provided to obtain information of skin blood vessels and blood flows.

Owner:HUAZHONG UNIV OF SCI & TECH

Wear-resistant pick-up lens

InactiveCN107229085ASolve the wear-resistantImprove wear resistanceOptical elementsCamera lensSurface layer

The invention discloses a wear-resistant camera lens, which comprises a camera lens. A layer of zirconia nanoparticle film is provided on the surface of the camera lens. The thickness of the zirconia nanoparticle film is 0.3-1.5 μm, and is sprayed by high-pressure spraying. A zirconia nanoparticle film is formed on the surface of the camera lens. By spraying a layer of zirconia nanoparticle film on the surface of the camera lens, due to the high light transmittance of zirconia nanoparticles, a wear-resistant layer is formed on the surface of the camera lens, and at the same time, it has an impact on the amount of light entering the camera lens and the captured image. little. After testing, the zirconia nanoparticle film formed on the surface of the camera lens has a zirconia content of more than 75%, a refractive index of 1.84, and excellent light transmittance. It is obtained through the test of the wear resistance of the coating film. Rarely, the front and rear light transmittances have little change, thus, the wear-resistant camera lens of the present invention has outstanding wear-resistant performance, which solves the problem of non-wear-resistant existing camera lenses.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com