Cesium tungsten system transparent heat insulation master batch and preparation method thereof

A kind of masterbatch and system technology, which is applied in the field of cesium tungsten system transparent heat insulation masterbatch and its preparation, can solve the problems that the heat insulation effect is difficult to meet, the dispersion of photochromic powder heat insulation glass is uneven and large-scale application, etc. , to achieve the effects of improving aging resistance stability, low haze, and uniform nano-dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

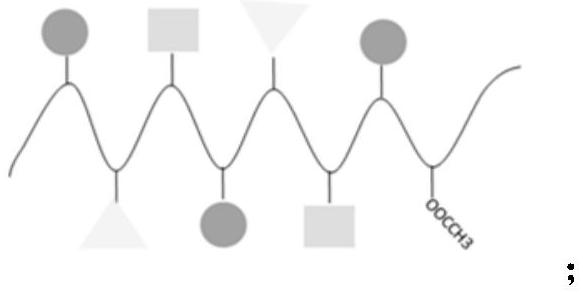

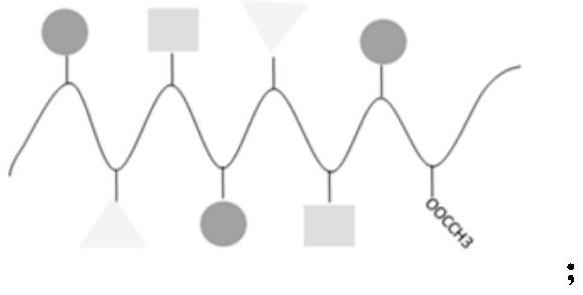

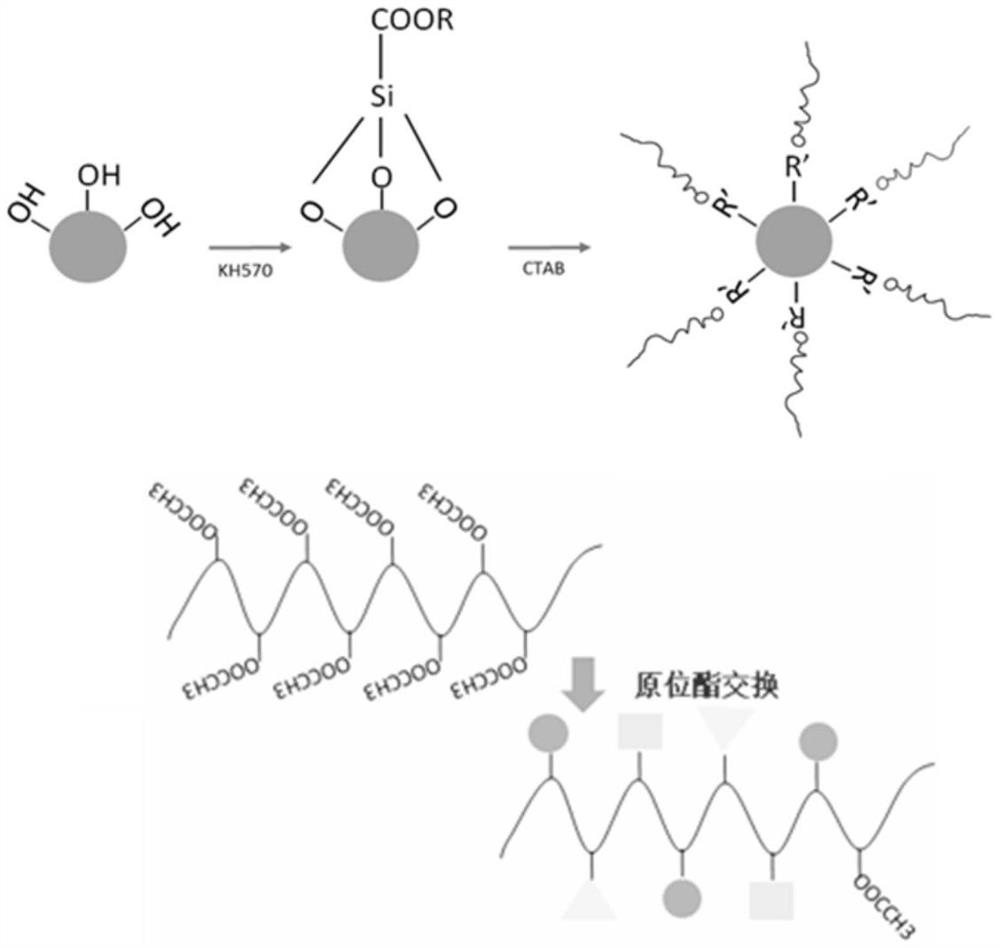

Method used

Image

Examples

Embodiment 1

[0023] 1. Cs 0.33 WO 3 Preparation of powder by solid state thermal method

[0024] Cs 0.33 WO 3 The preparation method of the powder comprises the following steps: mixing the cesium carbonate white powder and the light yellow powder of tungsten trioxide with a Cs / W molar ratio of 1:3 into a container containing deionized water, and placing it on a heating table; Under the action of mechanical stirring, the temperature of the heating table was increased to 130 ° C, and the water vapor was gradually evaporated to dryness; finally, the obtained powder was ground with a nano-sand mill for 2 hours, and sieved with a 500-800 mesh screen. The sieved powder was placed in a tube furnace, at H 2 / N 2 (5% / 95%) high temperature heat treatment at 700°C for 3h to obtain dark blue cesium tungstate powder.

[0025] 2. Modified Cs 0.33 WO 3 Nanopaste preparation

[0026] (1) Raw materials

[0027] The modified Cs 0.33 WO 3 The raw materials included in the preparation of the nanos...

Embodiment 2

[0040] 1. Cs 0.33 WO 3 Preparation of powder by solid state thermal method

[0041] Cs0.33 WO 3 The preparation method of the powder comprises the following steps: mixing the cesium carbonate white powder and the light yellow powder of tungsten trioxide with a Cs / W molar ratio of 1:3 into a container containing deionized water, and placing it on a heating table; Under the action of mechanical stirring, the temperature of the heating table was increased to 120 ° C, and the water vapor was gradually evaporated to dryness; finally, the obtained powder was ground with a nano-sand mill for 1 hour, and sieved with a 500-800 mesh screen. The sieved powder was placed in a tube furnace, at H 2 / N 2 (5% / 95%) high temperature heat treatment at 650°C for 5h to obtain dark blue cesium tungstate powder.

[0042] 2. Modified Cs 0.33 WO 3 Nanopaste preparation

[0043] (1) Raw materials

[0044] The modified Cs 0.33 WO 3 The raw materials included in the preparation of the nanoslur...

Embodiment 3

[0057] 1. Cs 0.33 WO 3 Preparation of powder by solid state thermal method

[0058] Cs 0.33 WO 3 The preparation method of the powder comprises the following steps: mixing the cesium carbonate white powder and the light yellow powder of tungsten trioxide with a Cs / W molar ratio of 1:3 into a container containing deionized water, and placing it on a heating table; Under the action of mechanical stirring, the temperature of the heating table was increased to 140 ° C, and the water vapor was gradually evaporated to dryness; finally, the obtained powder was ground with a nano-sand mill for 3 hours, and sieved with a 500-800 mesh screen. The sieved powder was placed in a tube furnace, at H 2 / N 2 (5% / 95%) high temperature heat treatment at 750°C for 2h to obtain dark blue cesium tungstate powder.

[0059] 2. Modified Cs 0.33 WO 3 Nanopaste preparation

[0060] (1) Raw materials

[0061] The modified Cs 0.33 WO 3 The raw materials included in the preparation of the nanos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com