Polymerizable composition for polythiourethane-based optical material

A technology of polymeric composition and optical material, which is applied in optics, optical components, optical components, etc., can solve problems such as changes and quality control difficulties, and achieve the effect of low yellowness index and uniform refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 50.7 parts by weight of m-xylene diisocyanate, 0.01 parts by weight of dibutyltin dichloride as a curing catalyst, 0.1 parts by weight of an internal release agent (manufacturer: Stepan, product name: UN, acidic alkyl phosphate release agent), 0.05 parts by weight of UV absorber (2-(2'-hydroxy-5'-tert-octylphenyl)-2H-benzotriazole, manufacturer: Cytec, product name: UV-5411) and 0.5 parts by weight of phosphoric acid were mixed at 25°C to obtain a mixture, 49.3 parts by weight of polythiol B was added to the mixture, and then uniformly mixed again to prepare a polymerizable composition.

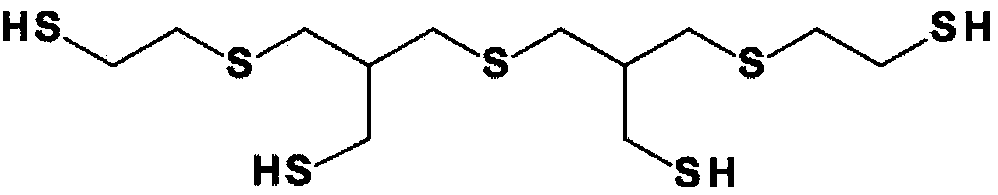

[0053] Polythiol B is bis(2-(2-mercaptoethylthio)-3-mercaptopropyl)sulfide represented by the following formula 1, and HPLC measurement under the following measurement conditions showed a high content of nitrogen-containing compound, and the peak area of the nitrogen-containing compound (B) / the peak area of the polythiol compound (A) was 7.8%.

[0054] In addition, the results ...

Embodiment 2-4 and comparative example 1-3

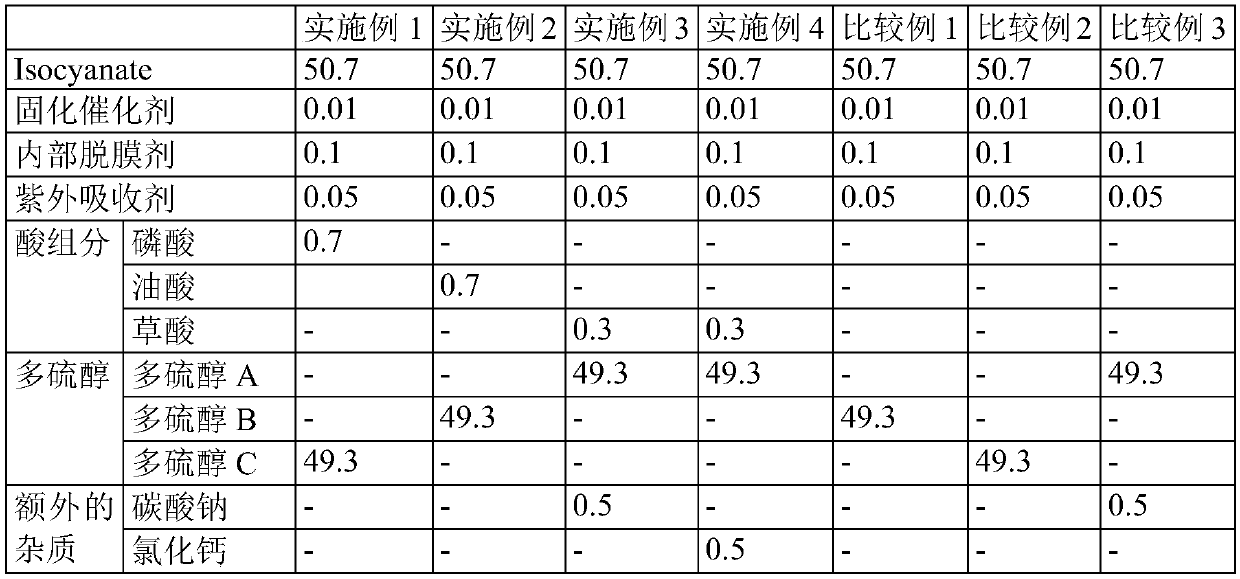

[0065] A polymerizable composition was prepared in the same manner as in Example 1 except for using the components and contents (parts by weight) shown in Table 1 below.

[0066] [Table 1]

[0067]

[0068] Polythiol A is bis(2-(2-mercaptoethylthio)-3-mercaptopropyl)sulfide represented by the above formula 1, and HPLC measurement under the same conditions as in Example 1 showed that B / A The percentage is 1.9%. In addition, ICP analysis showed that polythiol A contained 1.0 ppm of Ca, 1.1 ppm of Mg, 1.2 ppm of K and 1.7 ppm of Na.

[0069] Polymercaptan C is bis(2-(2-mercaptoethylthio)-3-mercaptopropyl) sulfide represented by the above formula 1, and HPLC measurement under the same measurement conditions as in Example 1 showed that B / A percentage is 2.8%. In addition, ICP analysis revealed that polythiol C contained 1.3 ppm Ca, 1.7 ppm Mg, 1.8 ppm K and 621 ppm Na, a high Na cation content.

experiment example

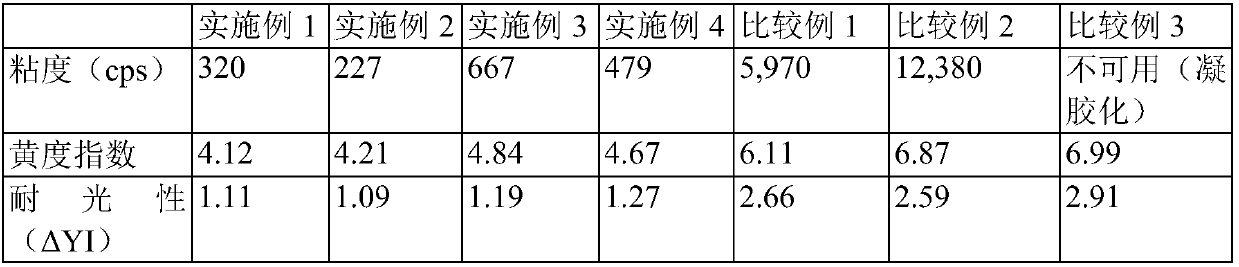

[0070] Experimental Example: Measurement of Physical Properties

[0071] The physical properties of the polymerizable compositions prepared in Examples 1-4 and Comparative Examples 1-3 were measured as follows, and the measurement results are shown in Table 2 below.

[0072] (1) Viscosity

[0073] After leaving the polymerizable composition at 25°C for 8 hours, the viscosity was measured at 25°C using a rotational viscometer.

[0074] (2) Yellowness index and light fastness (ΔYI)

[0075] The polymerizable compositions prepared in Examples 1-4 and Comparative Examples 1-3 were degassed at 600 Pa for 1 hour, and then filtered in a 3 μm Teflon filter. The filtered polymerizable composition was injected into a glass mold assembled by adhesive tape. The temperature of the mold was raised from 25°C to 120°C at a rate of 5°C / min, and polymerization was carried out at 120°C for 18 hours. The resin cured in the glass mold was further cured at 130° C. for 4 hours, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com