Method of making inorganic, metal oxide spheres using microstructured molds

A technology of inorganic metals and oxides, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of high cost and energy consumption, reduce waste, increase processing speed, improve overall utilization rate and output rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

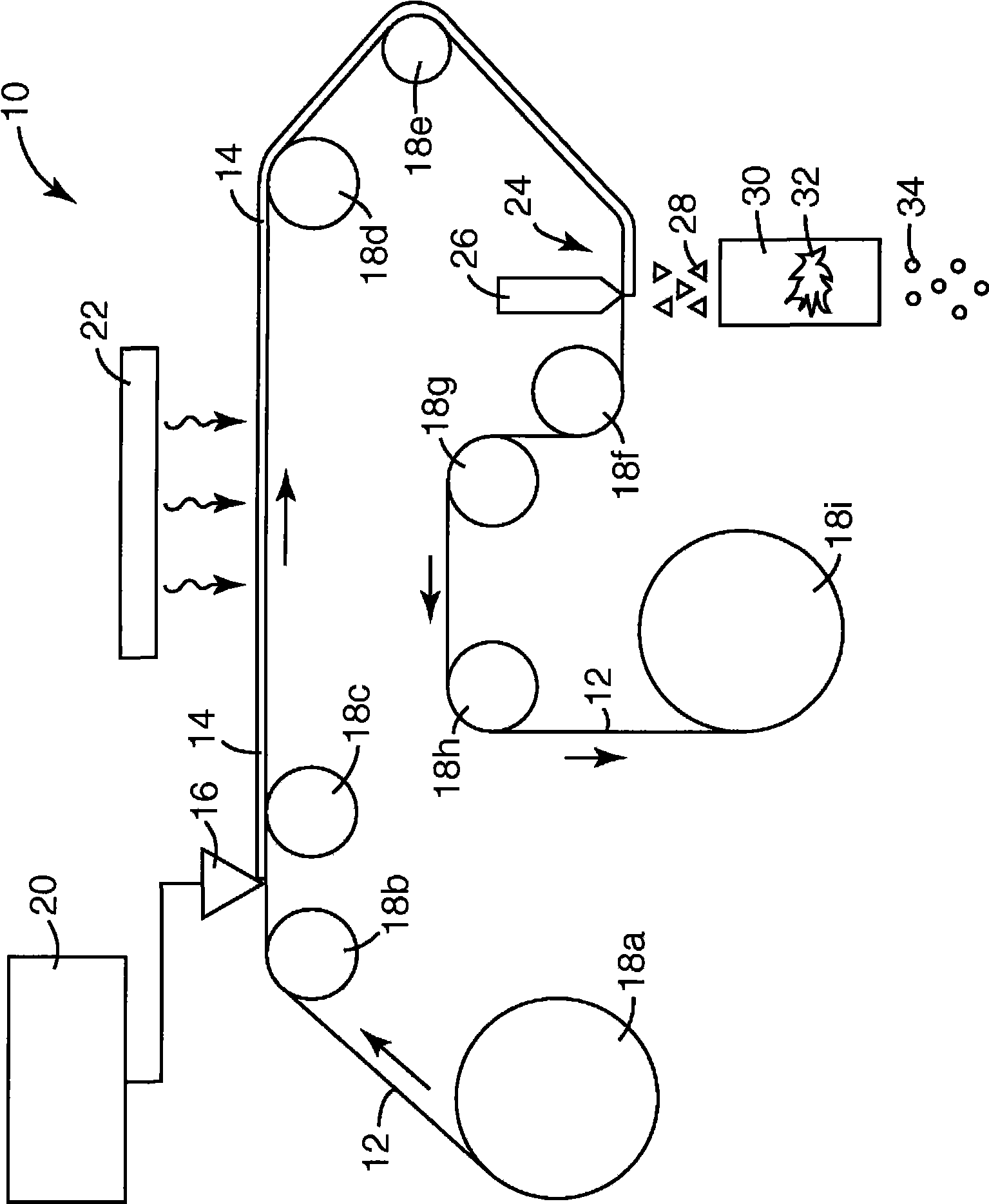

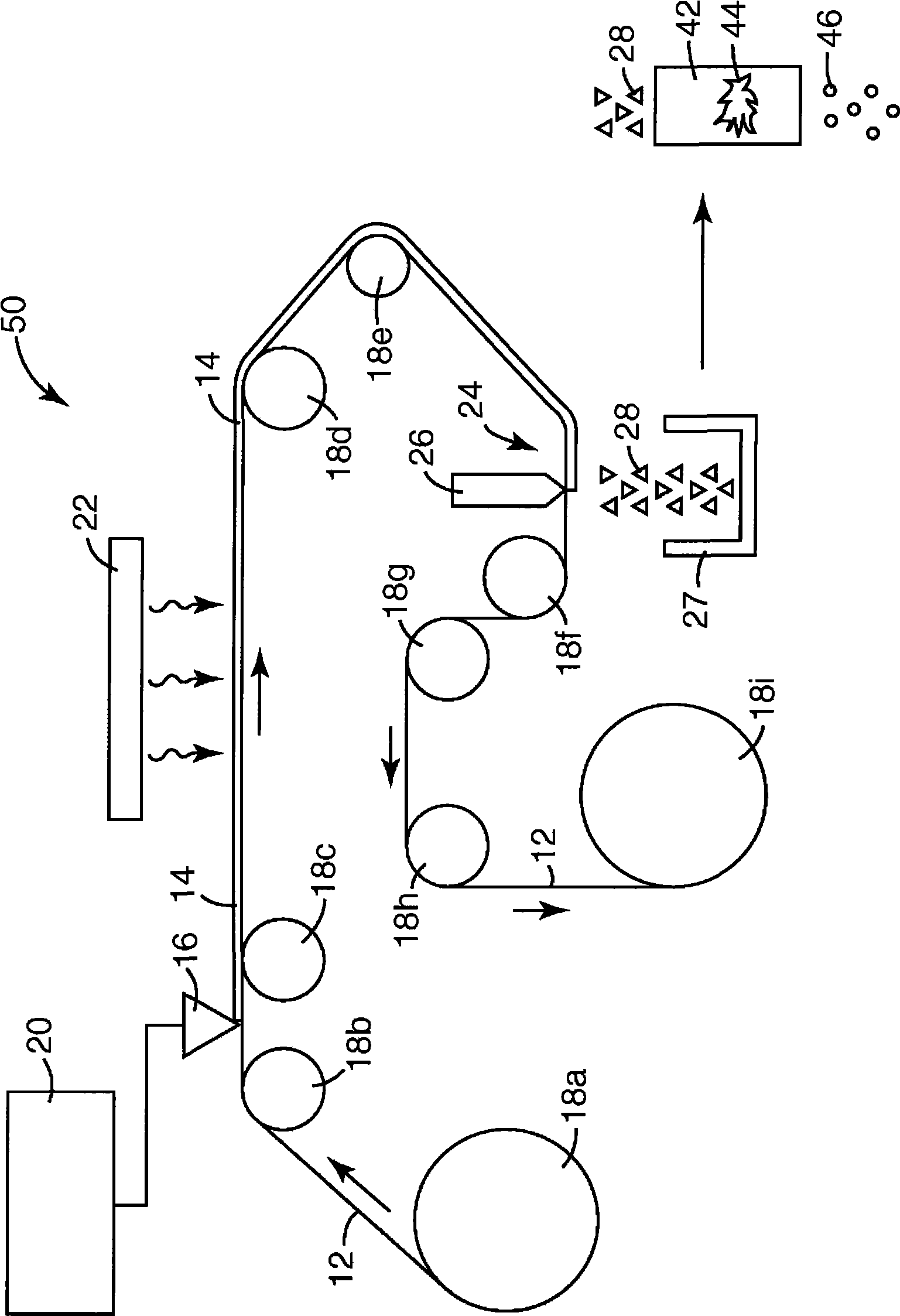

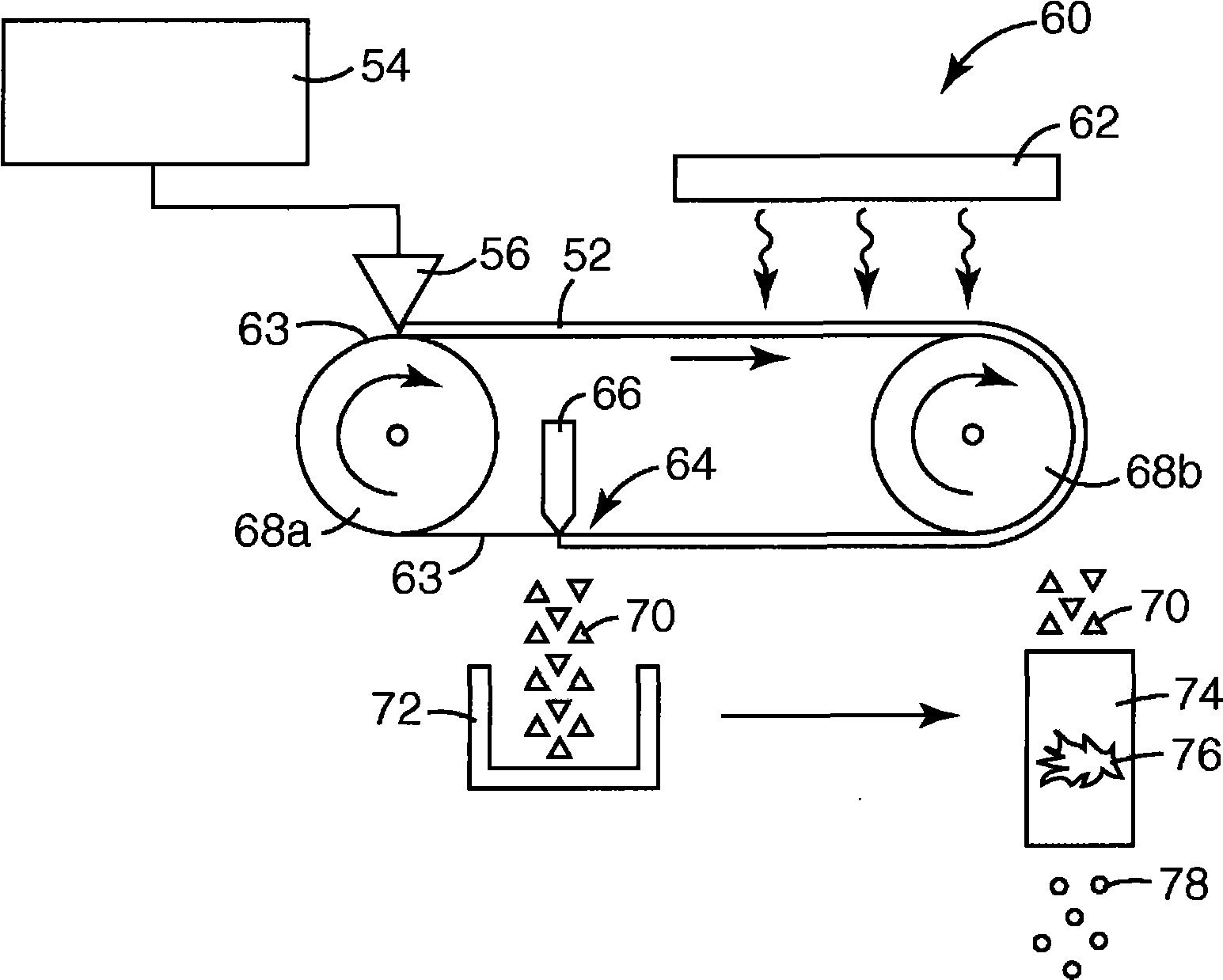

Method used

Image

Examples

example 1

[0106] A 52% solids slurry was prepared by combining 35.00 g of titanium dioxide, 11.00 g of silicon dioxide, 59.20 g of barium carbonate, 10.71 g of calcium carbonate, and 3.81 g of sodium borate while mixing. Prepare powder. 54g of deionized water was added to 96.07g of the powder to form a 64% solids slurry. The slurry was placed in a ceramic grinding jar filled with zirconia media and ground for 4 days. An additional 10 g of deionized water was added on the third day of milling and 25 g of deionized water was added on the fourth day for a total of 89 g of water to obtain a slurry with 52% solids. Then 1.92 g of surfactant and 8.96 g of D sodium silicate liquid binder (PQ Corporation, Berwyn, PA) were added to the slurry.

[0107] The resulting composition was then manually spread with a squeegee on a surface with a 2.4 x 10 7 cc tapered micro-mold on the tool to fill the mold. The filled molds were placed in an oven at 204.8°F (96°C) and dried for 3 hours. The molded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com