Conical spiral crusher

A pulverizer and screw technology, applied in the field of conical screw pulverizers, can solve the problems of high cost, non-adjustable powder size, difficult maintenance, etc., and achieve the effect of reasonable structure and good grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

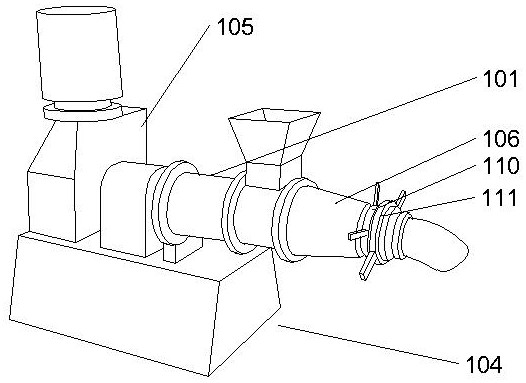

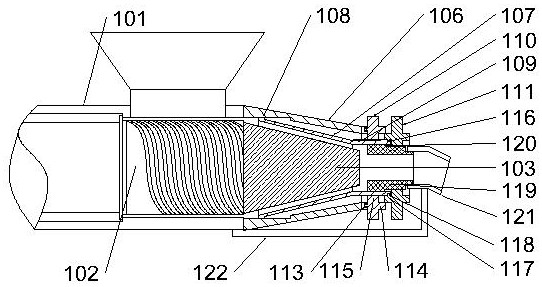

[0013] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , a kind of conical spiral pulverizer described in the present embodiment comprises organic shell 101, screw feeding shaft 102, frame 104, and the speed reducer 105 is installed on one end of frame 104 top, and organic shell 101 is installed on the other end of frame 104 , a screw feed shaft 102 is installed horizontally in the casing 101, one end of the screw feed shaft 102 shrinks to form a transmission shaft, the transmission shaft passes through the casing 101 and is connected to the output end of the reducer 105, and on the casing 101 above the screw feed shaft 102 A feed hopper is installed, and the other end of the screw feeding shaft 102 is connected with a fine grinding assembly, and a rough grinding area is formed between the screw feeding shaft 102 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com