Glass melting device and melting method therefor

A melting device and glass technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of reducing the quality of glass melting, affecting the service life, and destroying the diversion of glass liquid, so as to reduce the platinum structure and corrosion Possibility of platinum structure, reduced chance of contact with outer crucible wall, effect of improved residence time concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

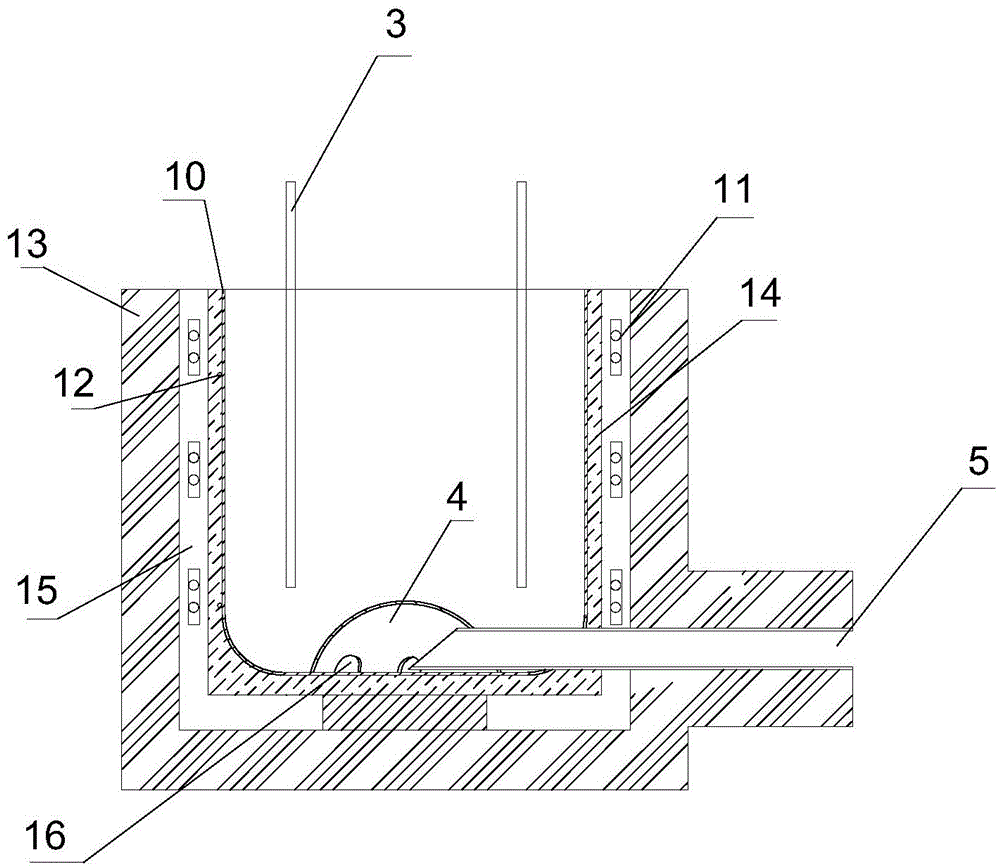

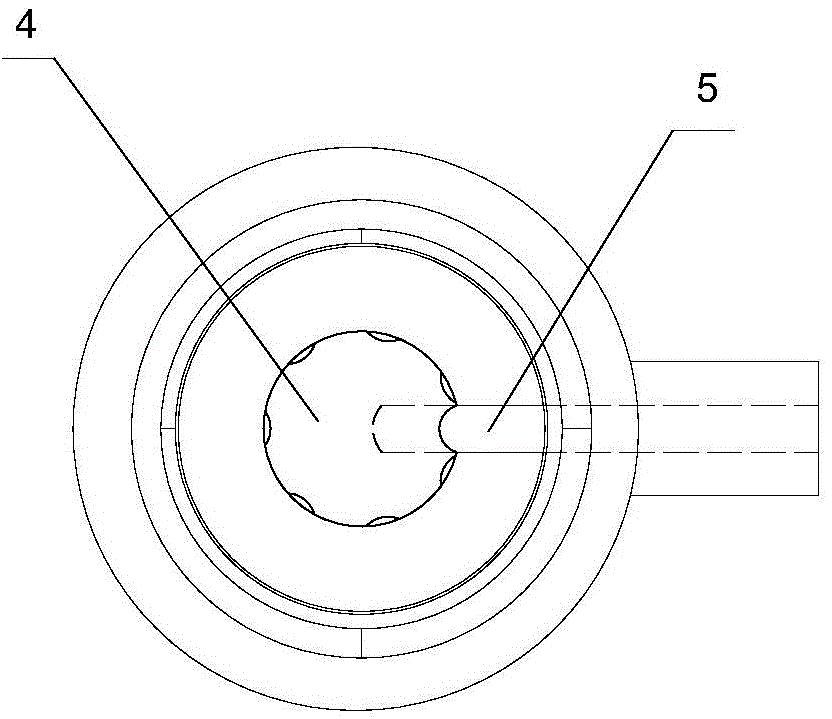

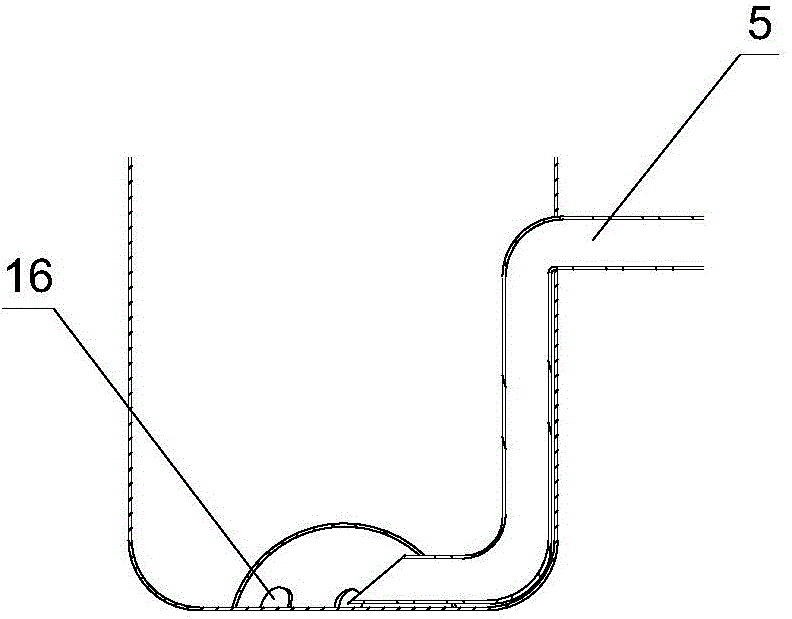

[0031] Such as Figure 1-Figure 2 As shown, the glass melting device of the present invention comprises an outer crucible 10, an inner crucible 4 of a convex surface structure, a bubbling pipe 3, a discharge pipe 5, a heating device 11, a temperature control device 12, a refractory material outer layer 13 and a refractory material inner layer14. The refractory inner layer 14 wraps the outer crucible 10, and a refractory outer layer 13 is also arranged outside the refractory inner layer 14, and a cavity 15 is spaced between the refractory outer layer 13 and the refractory inner layer 14. A heating device 11 is arranged in the cavity 15 .

[0032] The main function of the outer layer of refractory material 13 is to reduce heat loss and provide the required strength support for the entire glass melting device.

[0033] In order to prevent air convection in the cavity 15 from affecting the heating effect, the present invention isolates the cavity 15 into several small cavities. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com