Pvc (polyvinyl chloride) heat-shrinkable film and preparation method thereof

A heat-shrinkable film and PVC resin technology, applied in the field of PVC heat-shrinkable film and its preparation, can solve the problems of restricting the use of PVC packaging materials, reducing the transparency of PVC materials, and prone to yellowing of PVC, and achieving excellent visible light transmittance , Improve transparency and improve processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

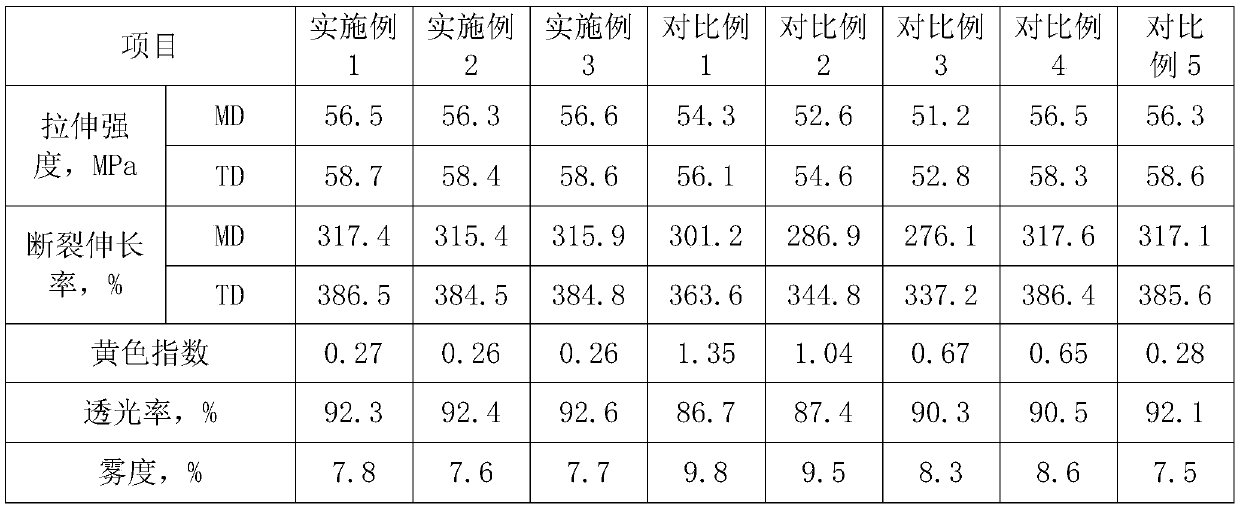

Examples

preparation example Construction

[0041] One, the preparation example of light stabilizer

[0042] The nano-titanium dioxide in the following preparations is selected from the model JL-TiO produced by Ningbo Jinlei Nano Material Technology Co., Ltd. 2 -8 rutile nano titanium dioxide; Tetraethyl orthosilicate is selected from the tetraethyl orthosilicate produced by Jinjinle Chemical; Zinc stearate is selected from the zinc stearate that the model produced by Shanghai Chuangyu Chemical Co., Ltd. is 5030; The polymethyl methacrylate is selected from the polymethyl methacrylate produced by Taiwan Chimei with the brand name of CM-203; the silane coupling agent is selected from the silane of the model KH-570 produced by Beijing Jintong Letai Chemical Products Co., Ltd. Coupling agent; triethanolamine is selected from the triethanolamine that the model that U.S. Dow Chemical produces is DOW.

preparation example 1

[0043] Preparation Example 1: ① Take 4kg of silane coupling agent and 1kg of triethanolamine, dissolve them in 20kg of absolute ethanol, and stir to obtain a mixed solution;

[0044] ②Take 10kg of nano-titanium dioxide, heat it up to 110°C, and keep it warm for 10 minutes; then add the mixed solution to the nano-titanium dioxide while stirring within 30 minutes, and stir at a speed of 300r / min for 1 hour to obtain modified nano-titanium dioxide;

[0045] ③Take 4kg of modified nano titanium dioxide, 1kg of tetraethyl orthosilicate, 1kg of zinc stearate, 0.5kg of hexahydrophthalic anhydride and 50kg of polymethyl methacrylate, heat up to 150°C, and use 200r / min After stirring at a high speed for 20 minutes, the light stabilizer was obtained after granulation and drying.

preparation example 2

[0046] Preparation Example 2: ① Take 5kg of silane coupling agent and 1.5kg of triethanolamine, dissolve them in 25kg of absolute ethanol, and stir to obtain a mixed solution;

[0047] ② Take 15kg of nano-titanium dioxide, heat it up to 115°C, and keep it warm for 15 minutes; then add the mixed solution to the nano-titanium dioxide while stirring within 30 minutes, and stir at a speed of 400r / min for 1.5h to obtain modified nano-titanium dioxide;

[0048] ③Take 5kg of modified nano titanium dioxide, 1.5kg of tetraethyl orthosilicate, 1.5kg of zinc stearate, 0.75kg of hexahydrophthalic anhydride and 55kg of polymethyl methacrylate, heat up to 155°C, and use 250r / After stirring at a speed of 25 min, the light stabilizer was obtained after granulation and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com