Silicon-dioxide optical waveguide production process for manufacturing optical divider

A silicon dioxide, optical splitter technology, applied in the direction of optical waveguide, light guide, optics, etc., can solve the problems of affecting the mechanical properties and thermal stability of the optical splitter, obvious birefringence effect, and large residual stress of materials. , to achieve the effects of improving mechanical properties and thermal stability, small internal residual stress, and uniform refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

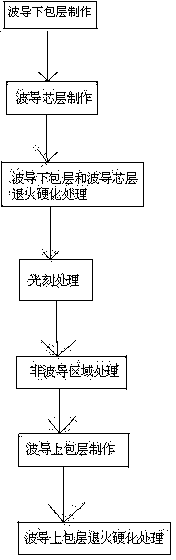

[0022] Such as figure 1 Shown, the present invention comprises the production technique for making the silicon dioxide optical waveguide of optical splitter, it is characterized in that, comprises the steps:

[0023] A. Fabrication of the lower cladding of the waveguide, using the flame hydrolysis method or chemical vapor deposition process, a layer of SiO2 is grown on the silicon wafer, and doped with phosphorus and boron ions as the lower cladding of the waveguide;

[0024] B. The waveguide core layer is made by flame hydrolysis or chemical vapor deposition process, and a layer of SiO2 is grown on the lower cladding layer as the waveguide core layer;

[0025] C. The waveguide lower cladding and waveguide core layer are annealed and hardened. Through the annealing and hardening process, the two layers of SiO2 grown in front become dense and uniform;

[0026] D. Photolithography treatment, protect the required waveguide pattern with photoresist;

[0027] E. For the non-waveg...

Embodiment 2

[0032] The preferred specific structure of this embodiment is as follows on the basis of the above embodiments: in step B, germanium ions are doped in the core layer of the waveguide. This layer is given the desired refractive index.

[0033] The lower cladding layer of the waveguide fabricated in step A, the core layer of the waveguide fabricated in step B, and the upper cladding layer of the waveguide fabricated in step F have the same thickness.

[0034] After the waveguide lower cladding layer and the waveguide core layer are annealed and hardened in step C, the refractive indices of the waveguide lower cladding layer and the waveguide core layer are uniform. The residual stress inside the material is further reduced, and the birefringence effect of the waveguide is reduced, so that the mechanical performance and thermal stability of the optical splitter made of the material are better.

[0035] After the annealing and hardening treatment of the upper cladding layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com