Optical switch element and its manufacturing method

An optical switch and component technology, which is applied in the manufacture of optical components, optics, semiconductor/solid-state devices, etc., can solve the problems of uneven impurity diffusion refractive index, inability to provide selectivity, uneven film thickness distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, a preferred embodiment to which the present invention is applied will be described in detail with reference to the accompanying drawings.

(Specific embodiment)

[0028] General structure of optical switching element

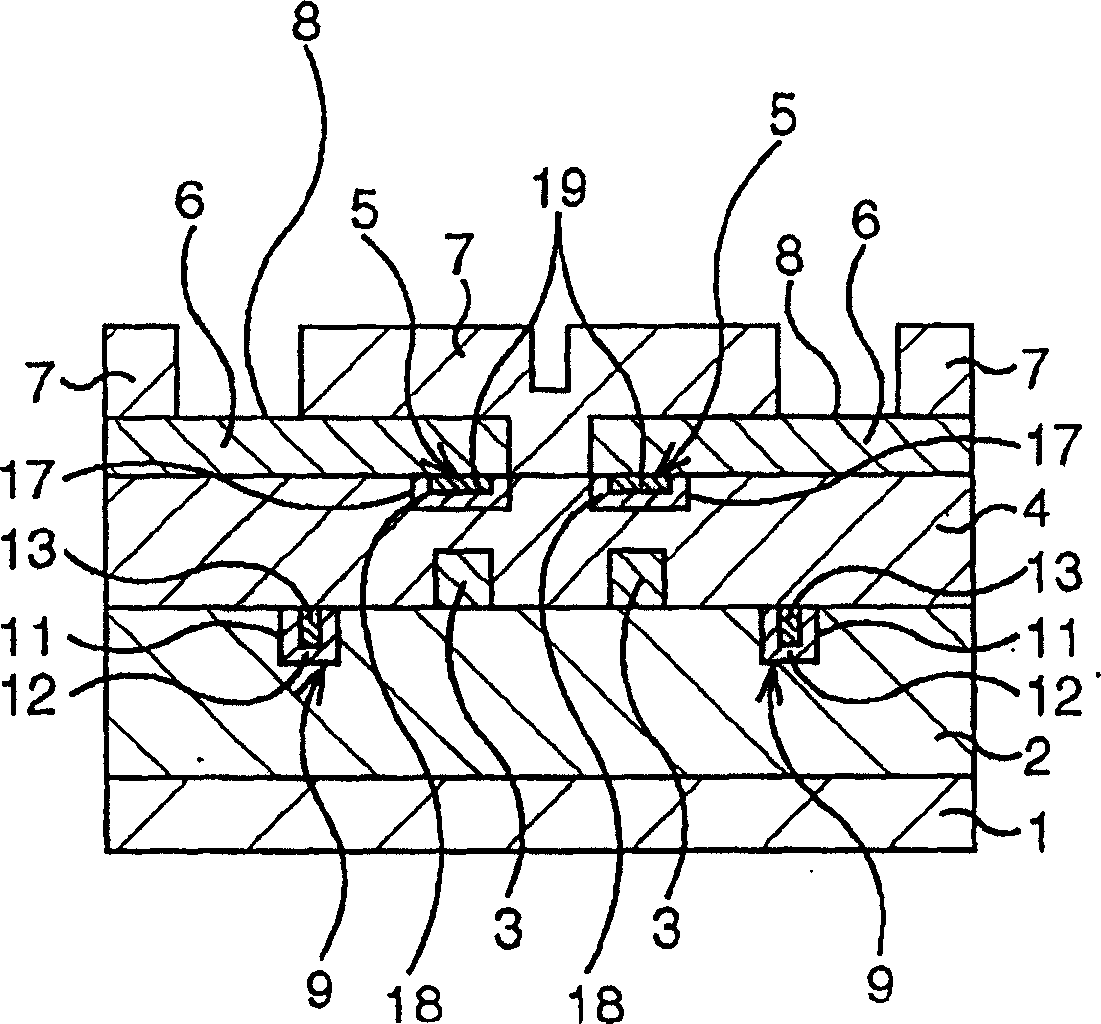

[0029] figure 1 It is a schematic cross-sectional view showing the general structure of the optical switch element according to the present embodiment.

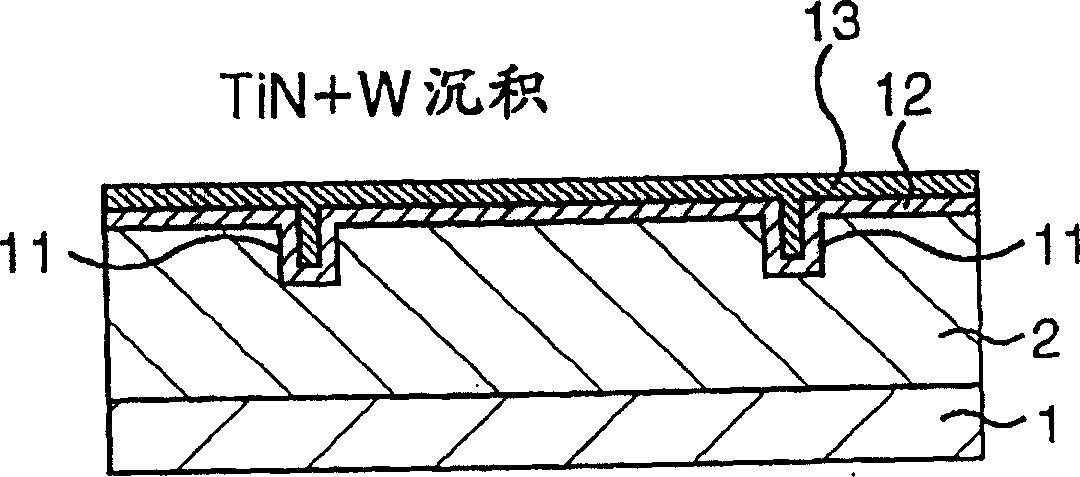

[0030] The optical switch element includes a silicon semiconductor substrate 1; an under-cladding layer 2 formed of a silicon oxide film on the silicon semiconductor substrate 1; each formed of a silicon oxide film and patterned on the under-cladding layer 2 so as to constitute a core 3 of an optical path; and Composed of a silicon oxide film formed on the lower cladding layer 2 so as to cover the upper cladding layer 4 of the core 3; heaters 5 composed of TiN and W sequentially embedded in the grooves formed above the core 3 The position corresponds to the surface layer part of the upper clad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com