Wear-resistant pick-up lens

A technology of camera lens and zirconia, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems that images contain shadows and line marks, are susceptible to scratches and abrasions, and affect the shooting performance of mobile phones, etc., so as to reduce the refractive index, Solve the effect of non-wear resistance and excellent light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

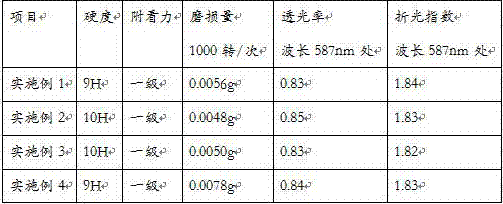

Examples

Embodiment 1

[0020] A wear-resistant camera lens, including a camera lens, the surface of the camera lens is provided with a layer of zirconia nanoparticle film, and the thickness of the zirconia nanoparticle film is 0.6 μm (for the convenience of subsequent tests, the uniform thickness is 0.6 μm, of course You can also choose 0.3μm, or 1.5μm), and spray it on the surface of the camera lens by high-pressure spraying to form a zirconia nanoparticle film. Furthermore, the preparation method of the zirconia nanoparticle film comprises the following steps:

[0021] Step 1, adding nano zirconia grains into ethanol and performing ultrasonic washing for 30 minutes, and then centrifuging to obtain washed nano zirconia grains;

[0022] Step 2. Add the nano-zirconia grains obtained in step 1 into tetrahydrofuran to dissolve and ultrasonically disperse for 20 minutes. Use sodium hydroxide to adjust the pH value of the solution to 12.5, and then add a proportioning amount of aminosilane coupling agent...

Embodiment 2

[0027] A wear-resistant camera lens, comprising a camera lens, the surface of the camera lens is provided with a layer of zirconia nanoparticle film, the thickness of the zirconia nanoparticle film is 0.6 μm, and is sprayed on the surface of the camera lens by high-pressure spraying to form Zirconia nanoparticle film. Furthermore, the preparation method of the zirconia nanoparticle film comprises the following steps:

[0028] Step 1, adding nano zirconia grains into ethanol and performing ultrasonic washing for 30 minutes, and then centrifuging to obtain washed nano zirconia grains;

[0029] Step 2. Add the nano-zirconia grains obtained in step 1 into tetrahydrofuran to dissolve and ultrasonically disperse for 20 minutes. Use sodium hydroxide to adjust the pH value of the solution to 13, and then add a proportioning amount of N-aminoethyl-γ-aminopropyl The methyldiethoxysilane coupling agent is reacted in a water bath at 90°C for 4-6h, then dried at 100°C for 1-3h, ground and...

Embodiment 3

[0034]A wear-resistant camera lens, comprising a camera lens, the surface of the camera lens is provided with a layer of zirconia nanoparticle film, the thickness of the zirconia nanoparticle film is 0.6 μm, and is sprayed on the surface of the camera lens by high-pressure spraying to form Zirconia nanoparticle film. Furthermore, the preparation method of the zirconia nanoparticle film comprises the following steps:

[0035] Step 1, adding nano zirconia crystal grains into ethanol and performing ultrasonic washing for 45 minutes, and then centrifuging to obtain washed nano zirconia crystal grains;

[0036] Step 2. Add the nano-zirconia grains obtained in step 1 into tetrahydrofuran to dissolve and ultrasonically disperse for 30 minutes. Use sodium hydroxide to adjust the pH value of the solution to 12, and then add a proportioning amount of γ-aminopropyltrimethoxysilane The coupling agent was reacted in a water bath at 90°C for 6h, then dried at 100°C for 3h, ground and sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com