Alloy ripper tooth on a ripper and manufacturing method thereof

A technology of loosening teeth and scarifiers, which is applied in fields such as tillage tools, agricultural machinery and implements, etc., and can solve the problems of short service life of loosening teeth, reduced work efficiency, and high production costs, and achieves improved binding force and energy saving Dosage, the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

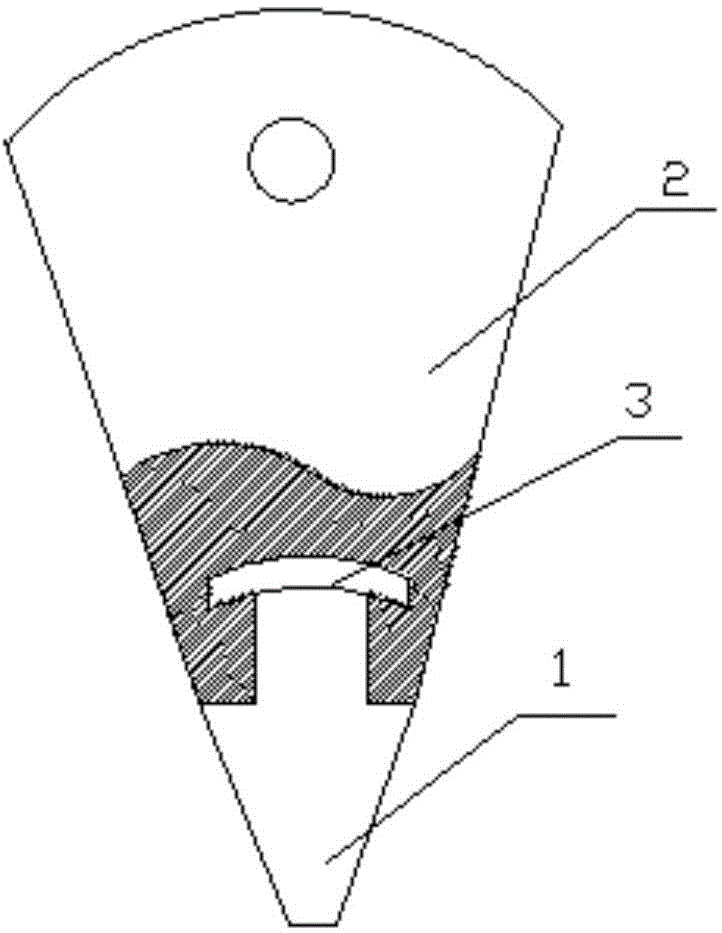

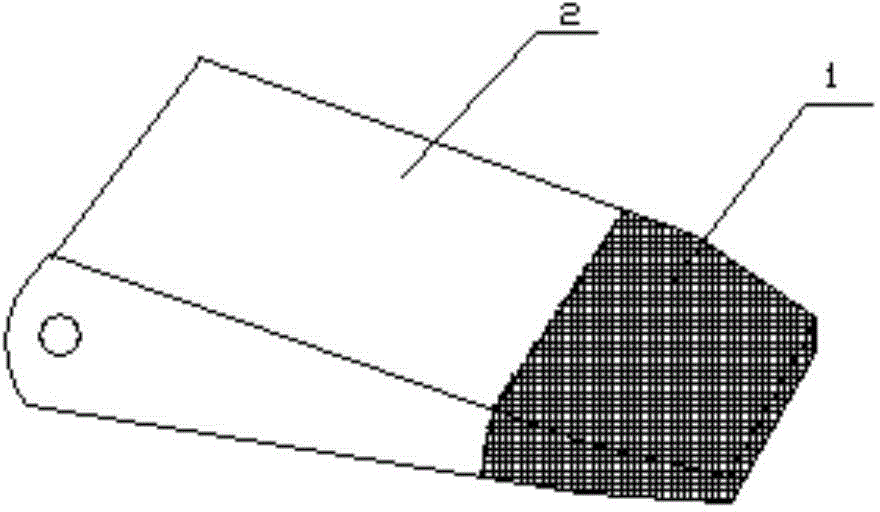

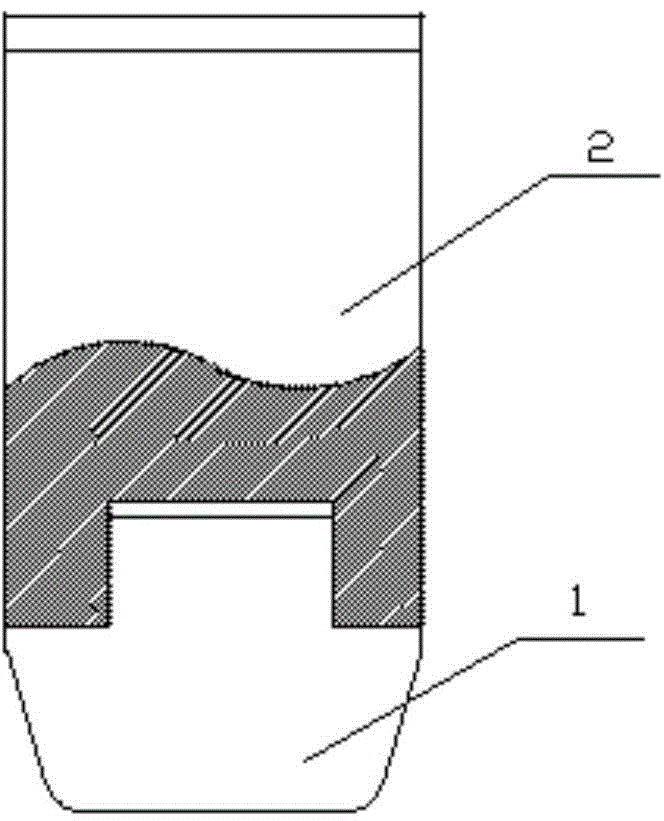

[0026] Embodiment 1: as Figures 1 to 3 As shown, an alloy loosening tooth on a scarifier includes two parts, the tooth tip 1 and the rear seat 2. The front end of the tooth tip 1 is trapezoidal, and the thickness of the front end is the thinnest. The rear end of the tooth tip 1 is connected to the rear seat 2 by casting, the material of the tooth tip 1 is alloy steel, and the material of the rear seat 2 is vermicular graphite cast iron.

[0027] The main function of the anti-off block 3 is to increase the contact area between the tooth tip and the back seat, improve the bonding force between the tooth tip and the back seat, and reduce the possibility of the tooth tip falling off. The anti-off block 3 can be flat or Arc-shaped, wherein the anti-off block 3 is arc-shaped and has stronger binding force.

[0028] The mass percentage of the chemical composition of the tooth tip is: C: 0.45%, Si: 1.1%, Mn: 1.7%, Nb: 0.08%, Mo: 0.2%, Ni: 0.25%, Cr: 1.8%, Al: 0.12% , Nd: 0.022%, B:...

Embodiment 2

[0042]Embodiment 2, the structure of this embodiment is the same as that of the loosening tooth described in embodiment 1.

[0043] The mass percentages of the chemical composition of the tooth tips in this embodiment are: C: 0.55%, Si: 1.3%, Mn: 1.9%, Nb: 0.1%, Mo: 0.25%, Ni: 0.3%, Cr: 2.1%, Al : 0.15%, Nd: 0.028%, B: 0.007%, S: 0.018%, P: 0.018%, the rest is Fe, the mass percentage of the chemical composition of the back seat is: C: 3.6%, Si: 2.3%, Mn: 0.6 %, Cr: 0.5%, Cu: 0.65%, S: 0.015%, P: 0.015%, and the rest is Fe.

[0044] The manufacturing method of the above-mentioned loosening tooth includes the following process steps:

[0045] 1. The production method of the tooth tip:

[0046] a. Put the raw materials for making tooth tips into the converter or intermediate frequency induction furnace for smelting;

[0047] b. The tapping temperature of the molten steel is about 1570°C. Add the rare earth alloy and stir for 3 minutes, then cast the alloy steel molten steel at...

Embodiment 3

[0057] Embodiment 3, the structure of this embodiment is the same as that of the loosening tooth described in Embodiment 1.

[0058] The mass percentages of the chemical components of the tooth tip described in this embodiment are: C: 0.3%, Si: 0.85%, Mn: 1.5%, Nb: 0.06%, Mo: 0.15%, Ni: 0.15%, Cr: 1.5%, Al: 0.09%, Nd: 0.015%, B: 0.003%, S: 0.015%, P: 0.015%, the rest is Fe, the mass percentage of the chemical composition of the back seat is: C: 2.6%, Si: 1.7%, Mn: 0.3%, Cr: 0.35%, Cu: 0.3%, S: 0.015%, P: 0.015%, and the rest is Fe.

[0059] The manufacturing method of the above-mentioned loosening tooth includes the following process steps:

[0060] 1. The production method of the tooth tip:

[0061] a. Put the raw materials for making tooth tips into the converter or intermediate frequency induction furnace for smelting;

[0062] b. The tapping temperature of the molten steel is about 1530°C. Add the rare earth alloy and stir for 2 minutes, then cast the alloy steel molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com