Method for making large size column mirror grating

The technology of a lenticular lens grating and a manufacturing method, which is applied in the field of optical device processing, can solve the problems that the large-size lenticular lens grating cannot meet the precision requirements, the surface shape of the bonding part is difficult to control, and the processing equipment requires high requirements, so as to improve the surface accuracy and operate The effect of simplicity and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

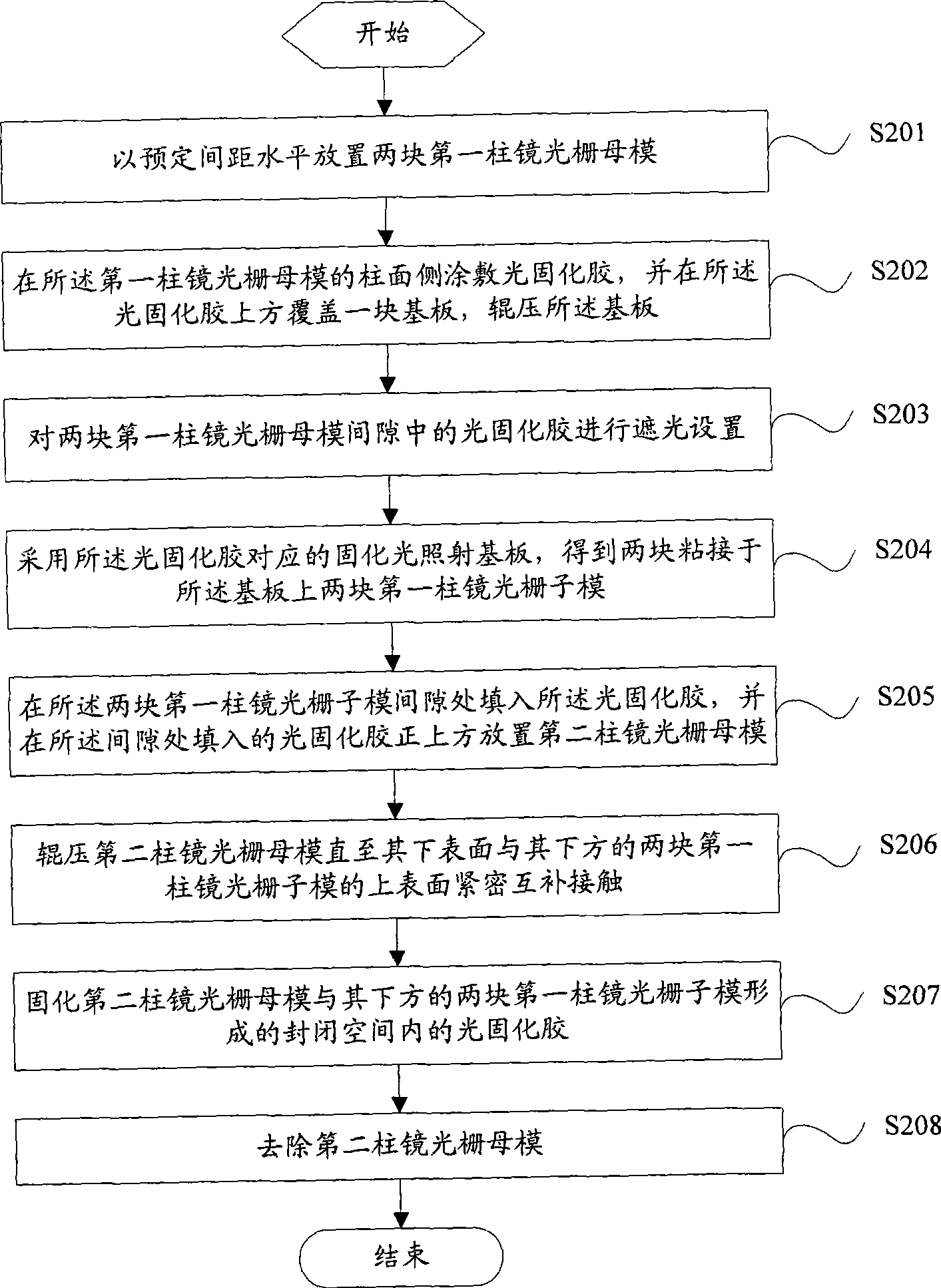

[0049] figure 2 Shown is a production flow chart of a large-size lenticular grating provided in this embodiment, including the following steps:

[0050] S201: Horizontally place two first lenticular master molds at a predetermined distance.

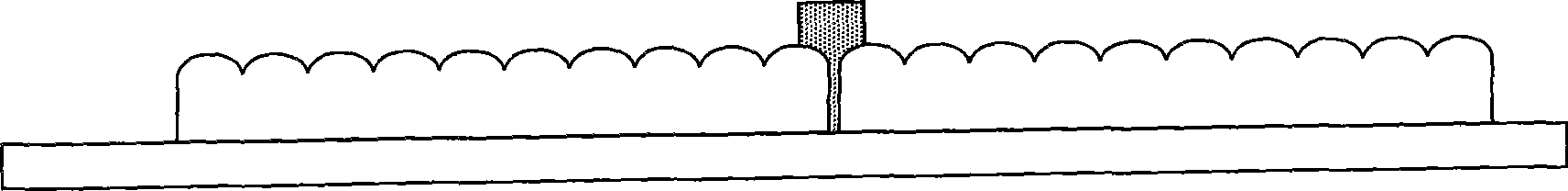

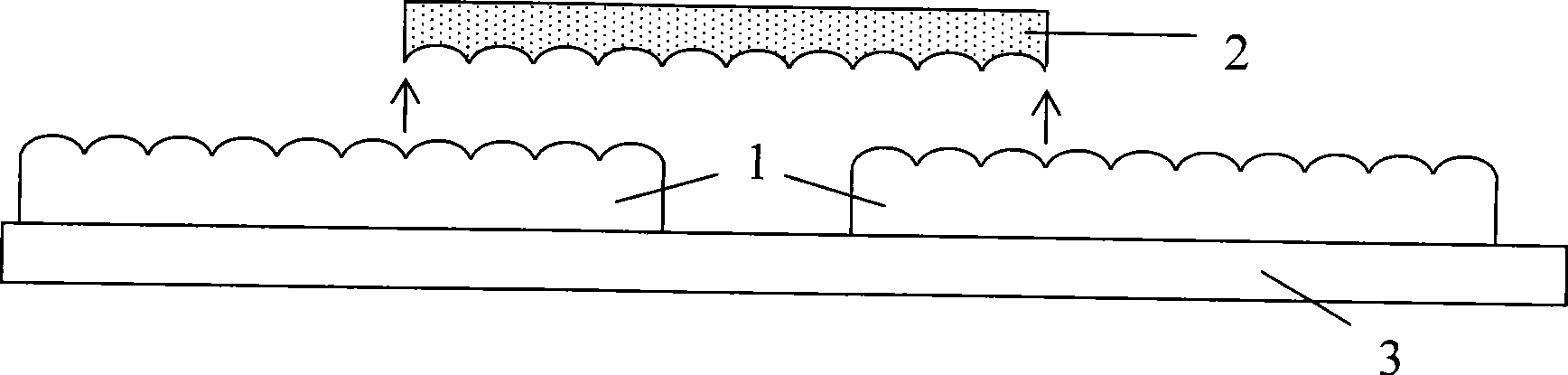

[0051]When setting, the two first lenticular grating master molds are at the same horizontal position, and the cylindrical generatrices of the two first lenticular grating master molds are parallel to each other, and the two first lenticular grating master molds are not in contact with each other . The distance between the complete groove surfaces of any two first lenticular master molds closest to each other is a positive integer multiple of the grating pitch of the first lenticular master mold. Here, the groove surface is: the interface between two adjacent cylindrical lenses on the cylindrical lens grating. Preferably, the predetermined distance between the two first lenticular master molds is determined by the third lenticular mas...

Embodiment 2

[0067] Figure 10 Shown is a production flow chart of a large-size lenticular grating provided in this embodiment, including the following steps:

[0068] S1001: Apply light-curing glue on the cylindrical surface of the fourth lenticular master mold placed horizontally, and cover a second substrate with a size much larger than the fourth lenticular master mold above the light-curing glue, Rolling the second substrate. Wherein, the light-curing glue is consistent with the light-curing glue used in Embodiment 1, and the size of the second substrate is much larger than the size of the fourth lenticular lens grating master mold. The schematic diagram of the specific device is as Figure 11 As shown: the fourth cylindrical lens grating master mold 13 is placed horizontally on the glass substrate 12 , the upper surface of the fourth cylindrical lens grating master mold 13 is coated with a photocurable glue 14 , and the photocurable glue 14 is covered with a second substrate 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com