PVC film for lamp box cloth and preparation method thereof

A technology of light box cloth and PVC resin, which is applied in applications, household appliances, flat products, etc., can solve the problems of PVC film being easily affected by temperature, poor thermal stability of PVC resin, and reducing the service life of light box cloth, so as to achieve improvement Effects of cold resistance and processing fluidity, excellent weather resistance, and good oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Table 1 is the raw material and quality of a kind of PVC film for light box cloth of Example 1

[0046] component Mass(kg) component Mass(kg) PVC resin 55 bentonite 1 MBS resin 12 Anatase Titanium Dioxide 3.8 Chlorinated polyethylene 5 Fluorescent whitening agent FP 0.01 Epoxidized soybean oil 20 UV-9 0.2 Calcium stearate 0.8 magnesium hydroxide 0.1 Zinc stearate 1.2 Oxidized polyethylene wax 0.1 Cadmium Stearate 0.5 ultramarine 0.005 ground calcium carbonate 70 permanent purple 0.002

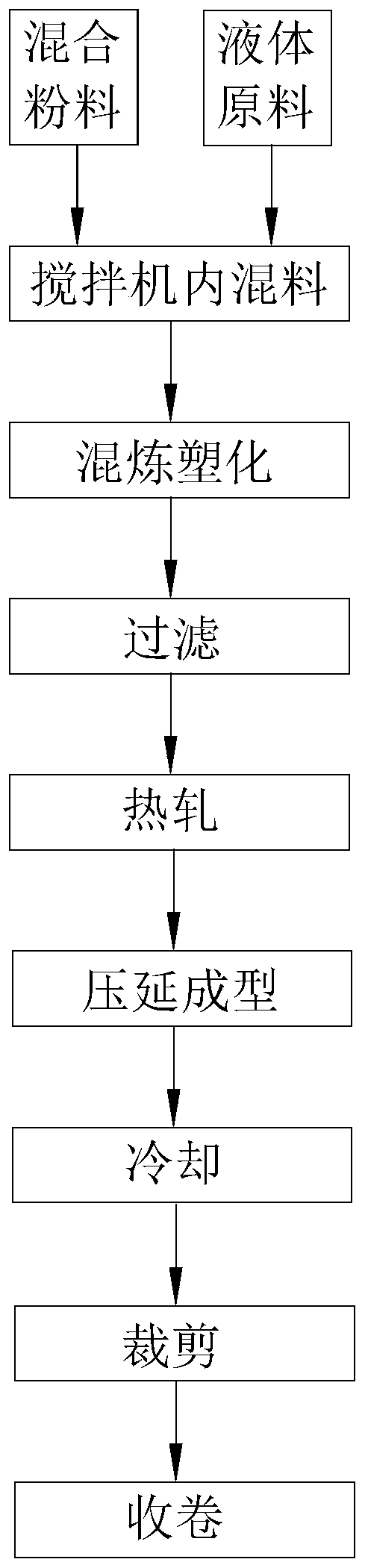

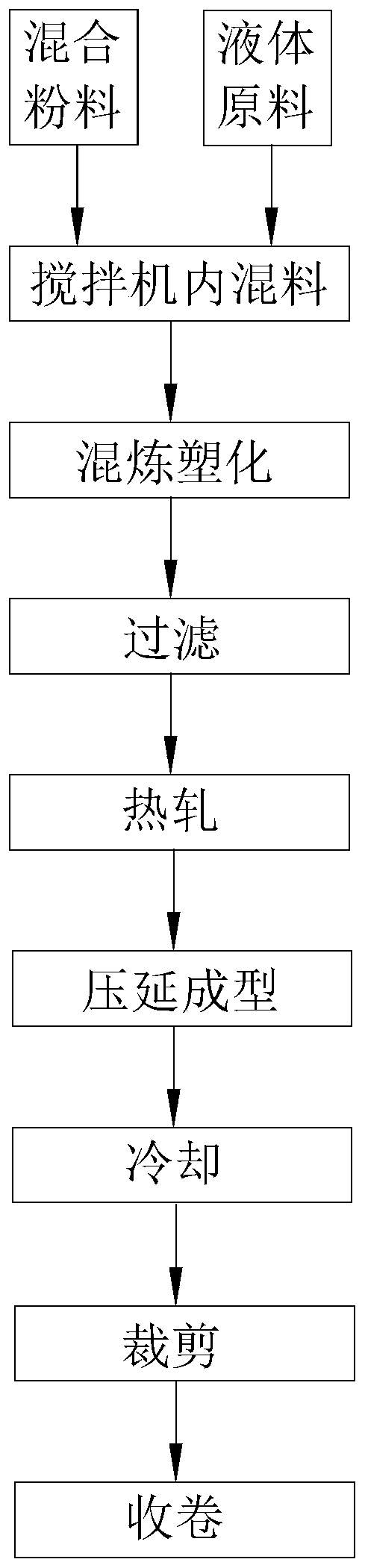

[0047] A preparation method of PVC film for light box cloth, which specifically comprises the following steps:

[0048] Step 1. Mixing powder: the powder raw materials in the formula in Table 1 are weighed and then transported to a high-speed mixer, where they are uniformly mixed to obtain a mixed powder;

[0049] Step 2, mixing: the mixed powder in step 1 is transported to the mixer, the liquid r...

Embodiment 2

[0058] Table 2 is each raw material and quality of a kind of PVC film for light box cloth of Example 2

[0059] component Mass(kg) component Mass(kg) PVC resin 60 bentonite 2 MBS resin 15 Anatase Titanium Dioxide 4 Chlorinated polyethylene 7.5 Fluorescent whitening agent FP 0.05 Dibutyl phthalate 15 UV-P 0.2 Zinc stearate 1 Aluminum hydroxide 0.1 Cadmium Stearate 1 Oxidized polyethylene wax 0.2 barium stearate 1 ultramarine 0.0055 ground calcium carbonate 75 permanent purple 0.0015

[0060] A preparation method of PVC film for light box cloth, which specifically comprises the following steps:

[0061] Step 1. Mixing powder: the powder raw materials in the formula in Table 2 are weighed and then transported to a high-speed mixer, and mixed evenly in the high-speed mixer to obtain a mixed powder;

[0062] Step 2, mixing: the mixed powder in step 1 is transported to the mixer, the liquid r...

Embodiment 3

[0071] Table 3 is each raw material and quality of a kind of PVC film for light box cloth of Example 3

[0072] component Mass(kg) component Mass(kg) PVC resin 65 ground calcium carbonate 72 MBS resin 10 bentonite 3 Chlorinated polyethylene 10 Anatase Titanium Dioxide 4.5 Epoxidized soybean oil 15 Fluorescent whitening agent FP 0.03 Dibutyl phthalate 5 UV-9 0.6 Calcium stearate 1.2 magnesium hydroxide 0.3 Zinc stearate 1.3 Oxidized polyethylene wax 0.3 Cadmium Stearate 0.5 ultramarine 0.005 barium stearate 0.5 permanent purple 0.005

[0073] A preparation method of PVC film for light box cloth, which specifically comprises the following steps:

[0074] Step 1. Mixing powder: the powder raw materials in the formula in Table 3 are weighed and then transported to a high-speed mixer, and mixed uniformly in the high-speed mixer to obtain a mixed powder;

[0075] Step 2, mixing: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com