Hydraulic system applied to hydraulic full-automatic unloading iron cutting machine

A hydraulic system and fully automatic technology, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve the problems of low blanking accuracy, high blanking cost, and many personnel requirements, so as to reduce personnel and improve products. The effect of high precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The applicant of this patent takes the workshop of Nan'an Jiejia Hydraulic Machinery Co., Ltd. as the specific implementation location of the technical solution of this patent, and provides the following specific examples:

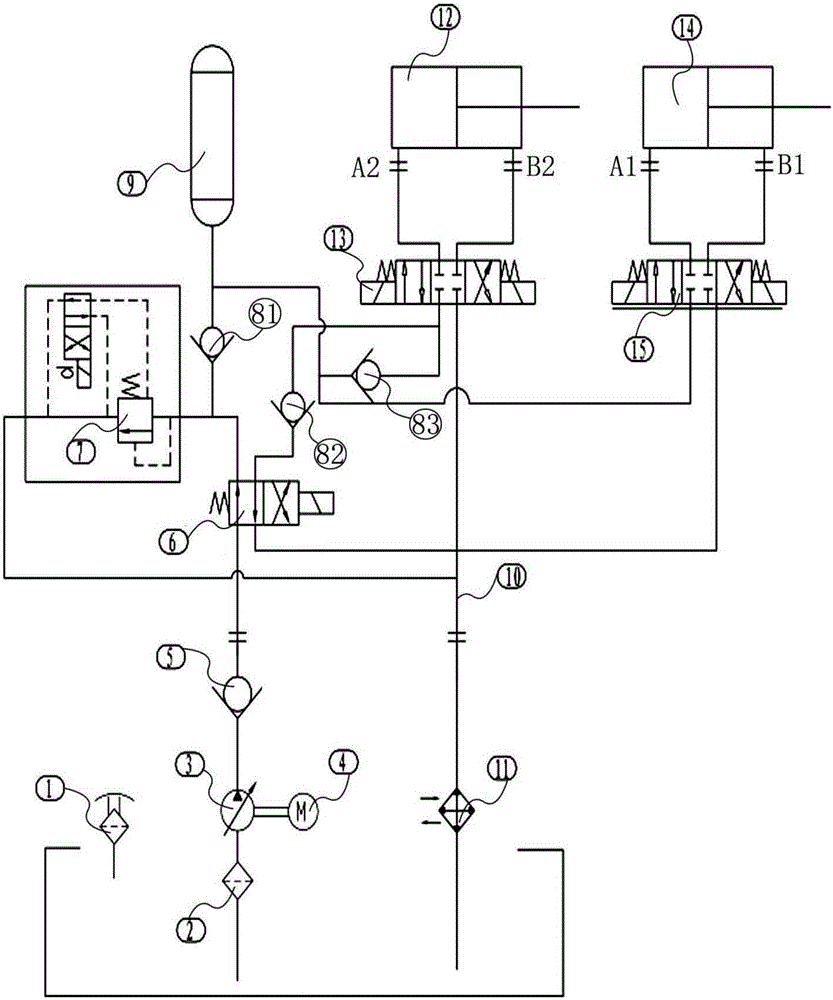

[0026] Such as figure 1 As shown, a hydraulic system applied to a hydraulic automatic blanking iron cutting machine is composed of a fuel tank 1, an oil suction net filter 2, an oil pump 3, a motor 4, a one-way valve, an electromagnetic reversing valve 6, an electromagnetic Relief valve 7, accumulator 9, oil circuit assembly 10, oil return cooler 11, cut-off cylinder 12, electro-hydraulic reversing valve 13, feeding cylinder 14, proportional flow reversing valve 15, characterized in that,

[0027] The oil tank 1 is connected to the oil suction net filter 2 through the oil circuit, the oil suction net filter 2 is connected to the oil pump 3 through the oil circuit, the motor 4 is connected to the oil pump 3, the motor 4 drives the oil pump 3 to run, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com