Stator punching piece, stator core and motor

A technology for stator punching and stator iron core, which is applied in the fields of stator motor and stator punching, can solve the problems of difficult mold manufacturing, high mold production cost, easy fracture of bridge 43, etc., so as to reduce the magnetic leakage phenomenon, The mold is simple and the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

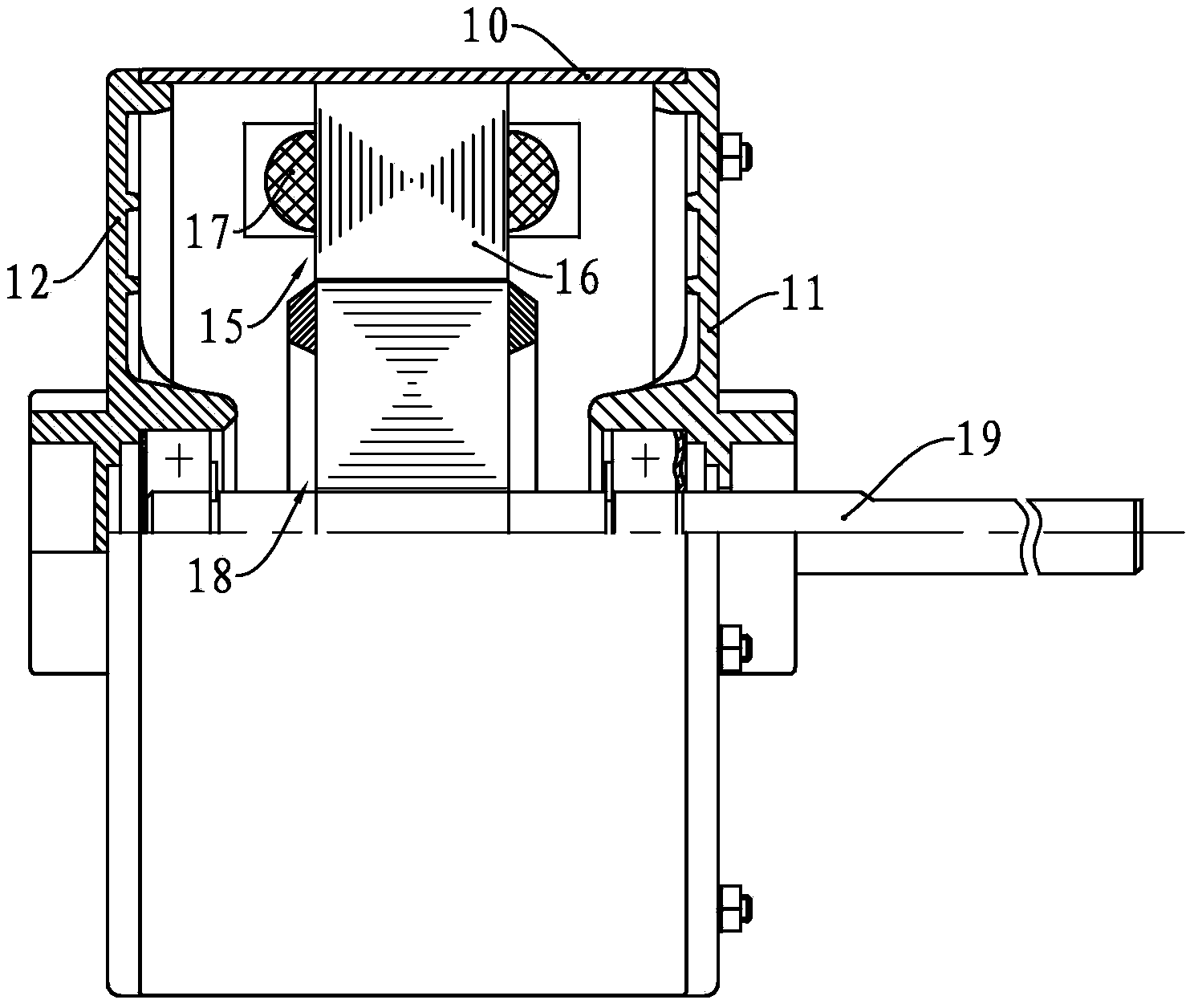

[0039] The motor of the present invention has a housing and end covers located on both sides of the housing. The housing and the end covers form a cavity. A stator and a rotor are installed in the cavity. A rotor mounting hole is provided in the middle of the stator. inside the hole. Moreover, the rotor shaft is installed in the middle of the rotor, and the rotor shaft can output power outward through the shaft hole.

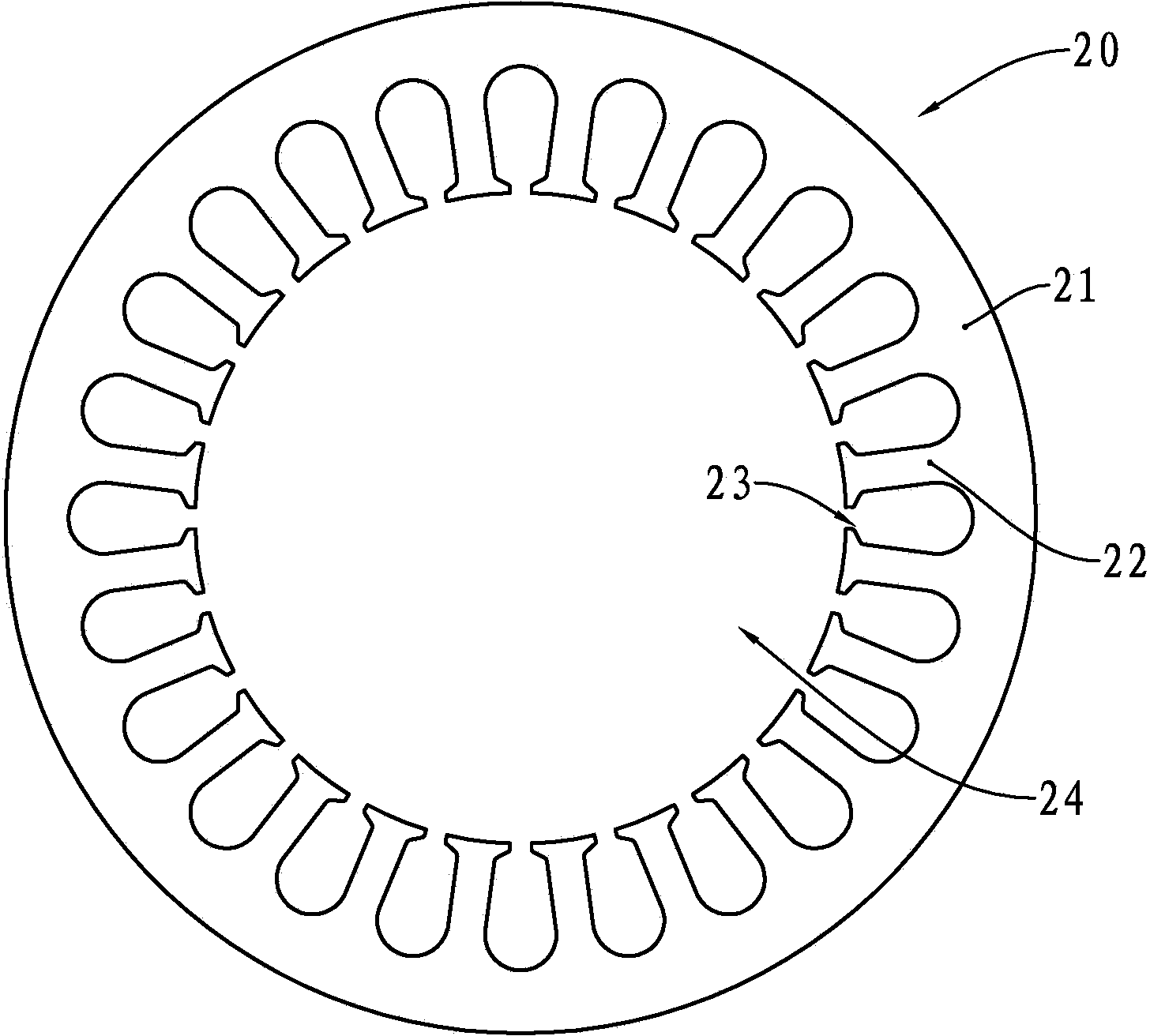

[0040] The stator of the present invention has a stator core. The stator core has a yoke and a tooth. The yoke is in the shape of an annular column. The tooth is located inside the yoke, and the tooth and the yoke are detachably connected.

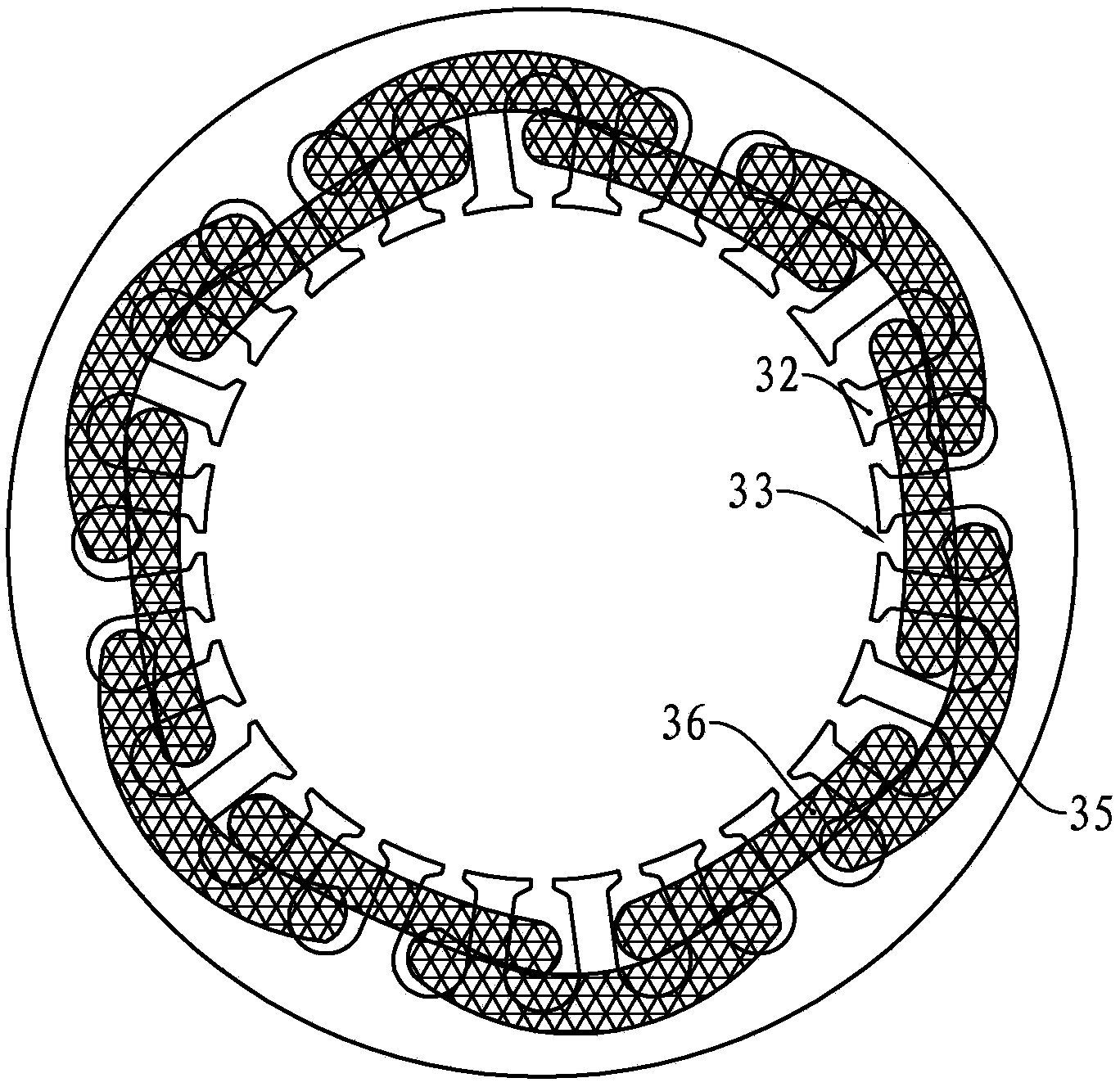

[0041] see Image 6 and Figure 7, the tooth portion 50 of this embodiment has three first tooth portions, namely the first tooth portions 51 , 53 , 55 , and two second tooth portions, respectively the second tooth portions 52 , 54 . In the axial direction of the tooth portion 50, the first tooth portion and the second to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com