Curved reflector

A curved mirror and spherical mirror technology, applied in the optical field, can solve the problems of increasing the difficulty of subsequent optical path processing and the cost of subsequent optical path processing, and achieve the effects of low cost, improved light efficiency, and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

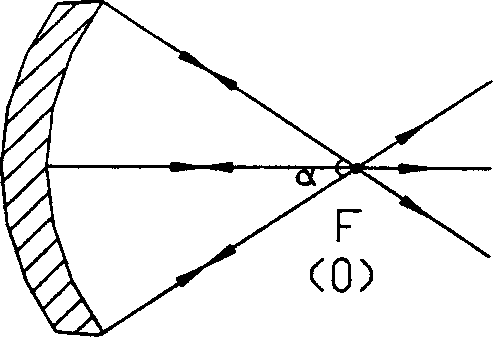

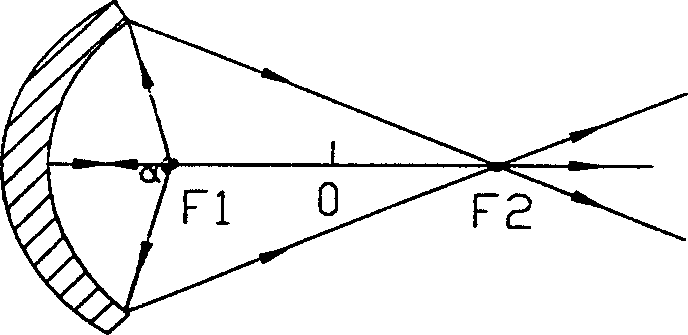

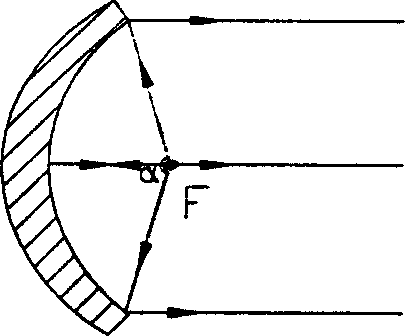

[0041] see image 3 , the curved reflector provided by the present invention is a composite curved reflector, including an ellipsoidal mirror 1 and a spherical mirror 2 . The ellipsoidal mirror 1 is coaxial with the spherical mirror 2 and their inner surfaces are oppositely arranged and combined together to form an irregular ellipsoid.

[0042] The ellipsoidal mirror 1 has two focal points F1 and F2, and the spherical mirror 2 has one focal point F. The focal point F of the spherical mirror 2 coincides with the focal point F1 of the ellipsoidal mirror 1 . The light source (not shown in the figure) is arranged at the coincident focus F1 of the ellipsoidal mirror 1 and the spherical mirror 2, that is, the ellipsoidal mirror 1 and the spherical mirror 2 are located on both sides of the light source. With the optical axis as the center, a circular hole 3 is opened on the spherical mirror 2, which serves as a channel for outputting light from the curved reflector.

[0043] The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com