Composite saggar as well as preparation method and application thereof

A saggar and particle size technology, applied in the field of refractory materials, can solve the problems of affecting the service life of the saggar, spalling, cracking, and low service life of the saggar, and achieve the effects of high cost performance, not easy to break, and good dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

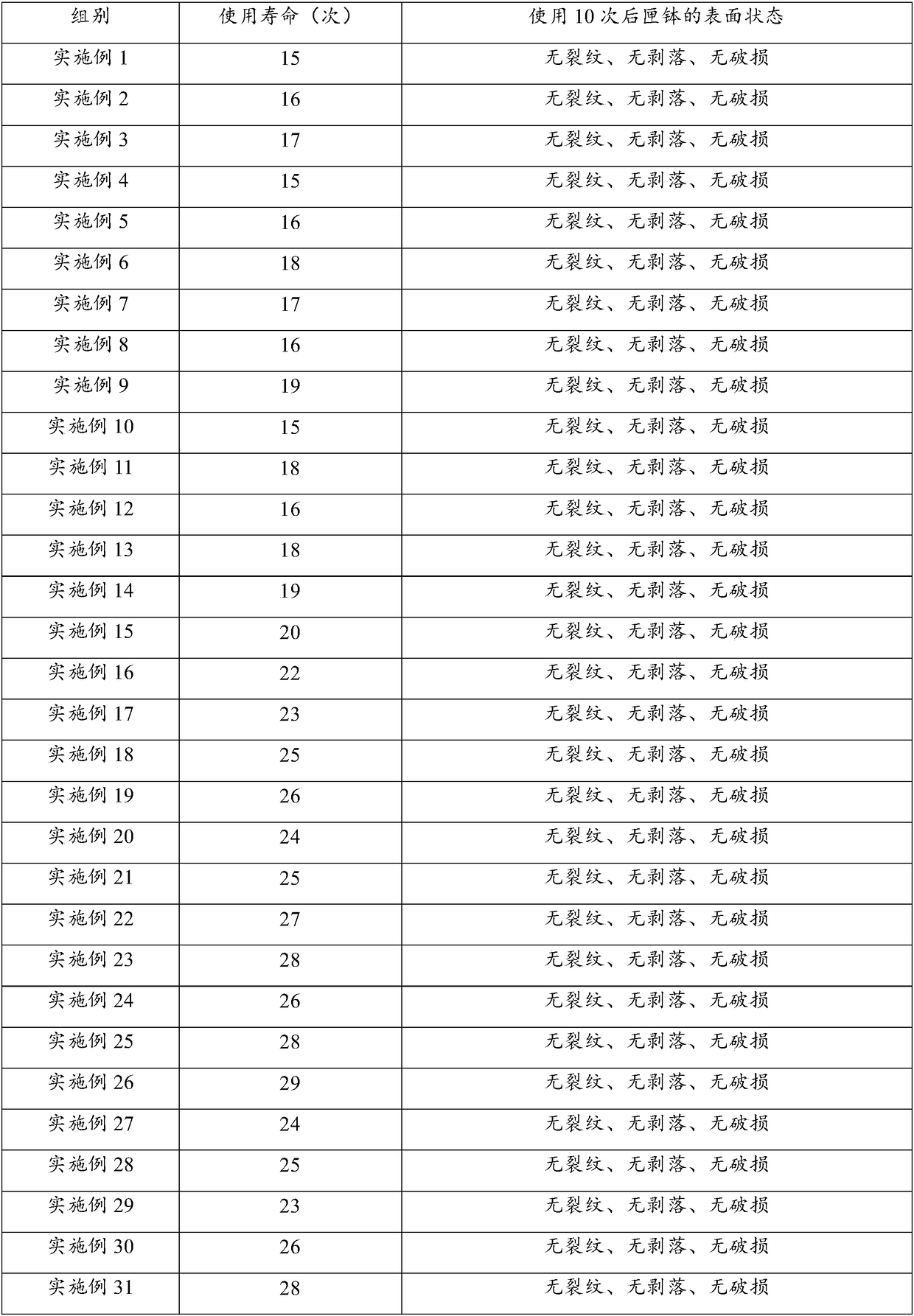

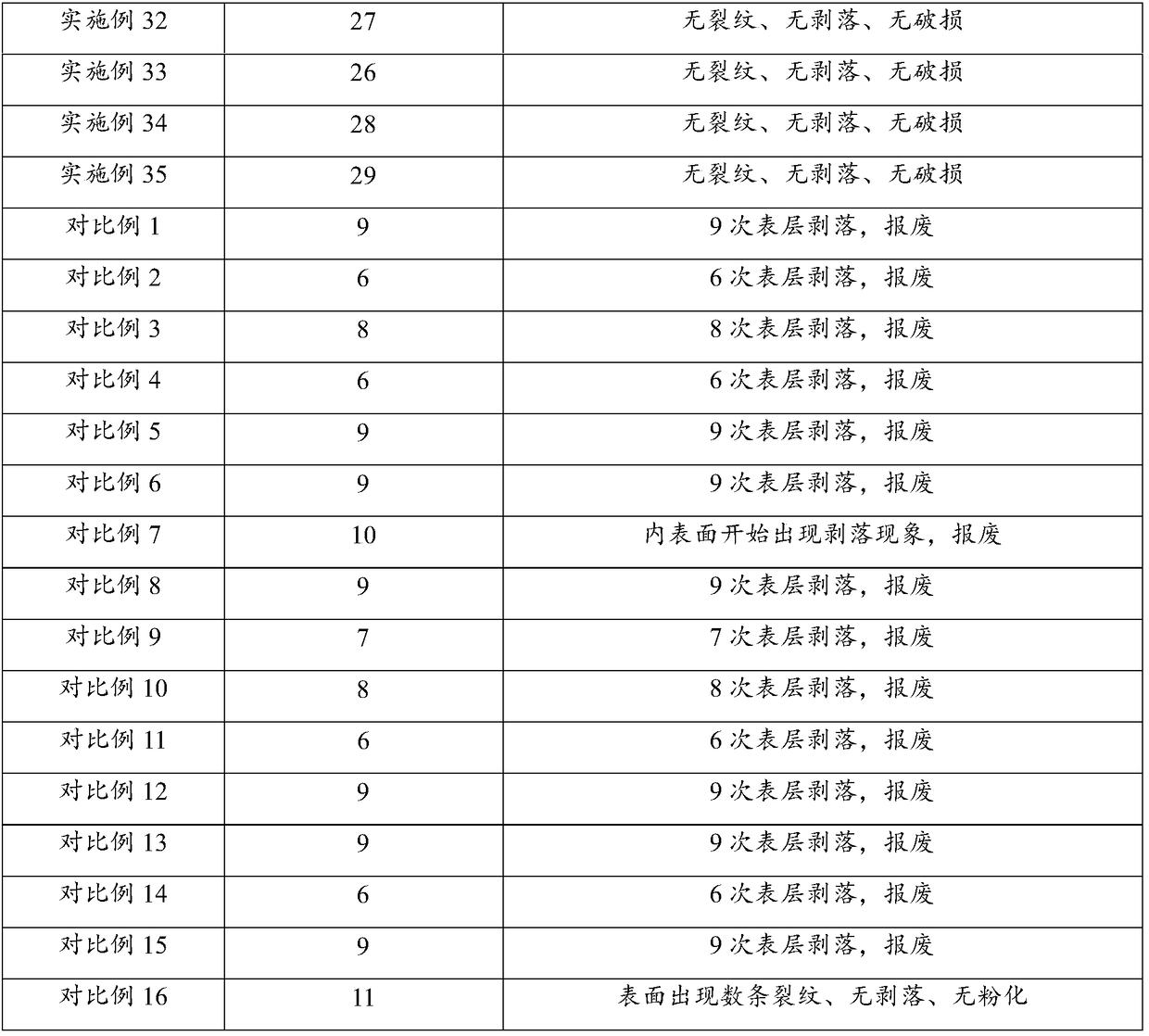

Examples

preparation example Construction

[0079] The present invention also provides a kind of preparation method of above-mentioned composite sagger, comprising the following steps:

[0080] (a) mix the base material raw materials of formula quantity uniformly, then add binding agent and mix again uniformly to obtain the base material mixture;

[0081] (b) uniformly mix the fabric raw materials of formula quantity, then add binding agent and mix again uniformly to obtain fabric compound;

[0082] (c) Add base material mixture and fabric mixture to mold successively, then molding obtains blank;

[0083] (d) curing the blank for 10-14 hours, then drying, and finally firing at a temperature of 1360-1410° C. for 3-5 hours to obtain the composite sagger.

[0084] The above curing time is typically but not limited to 10 hours, 10.5 hours, 11 hours, 11.5 hours, 12 hours, 12.5 hours, 13 hours, 13.5 hours or 14 hours. The curing method can be done according to the commonly used methods in this field, such as curing in a dry...

Embodiment 1

[0092] Embodiment 1 corundum fabric

[0093] A composite sagger, including a base material and a corundum fabric, the mass ratio of the base material and the corundum fabric is 7:3, and the base material is mainly prepared from the following base material raw materials in parts by mass: 8 parts of kaolin, 6 parts of sillimanite , 6 parts of alumina with particle size not greater than 46.9 μm, 12 parts of corundum with particle size not greater than 46.9 μm, 10 parts of andalusite with particle size not greater than 0.5 mm, 15 parts of mullite with particle size not greater than 1 mm, particle size 8 parts of mullite with a particle size of 1-2 mm and 6 parts of corundum with a particle size not greater than 1 mm;

[0094] The corundum fabric is mainly prepared from the following fabric raw materials in parts by mass: 10 parts of alumina with a particle size not greater than 0.7 μm, 5 parts of α-alumina with a particle size not greater than 46.9 μm, and 20 parts of corundum wit...

Embodiment 2

[0095] Embodiment 2 corundum fabric

[0096] A composite sagger, including a base material and a corundum fabric, the mass ratio of the base material and the corundum fabric is 9:1, and the base material is mainly prepared from the following base material raw materials in parts by mass: 12 parts of kaolin and 10 parts of sillimanite , 14 parts of alumina with particle size not greater than 46.9 μm, 22 parts of corundum with particle size not greater than 46.9 μm, 20 parts of andalusite with particle size not greater than 0.5 mm, 25 parts of mullite with particle size not greater than 1 mm, particle size 12 parts of mullite with a particle size of 1-2 mm and 14 parts of corundum with a particle size not greater than 1 mm;

[0097] The corundum fabric is mainly prepared from the following fabric materials in parts by mass: 20 parts of alumina with a particle size not greater than 0.7 μm, 15 parts of α-alumina with a particle size not greater than 46.9 μm, and 30 parts of corundu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com