Double-layer assembling keel for suspended ceiling

A keel and double-layer technology, which is applied in the field of assembling keels for double-layer ceilings, can solve the problems that the structure of the concealed frame ceiling cannot meet the requirements, and achieve good dustproof and sound insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

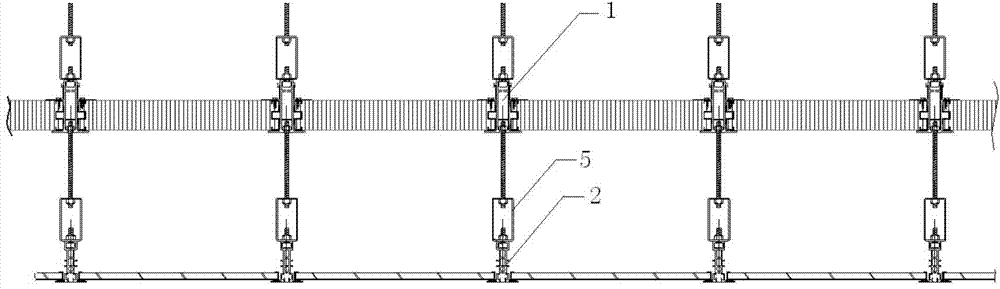

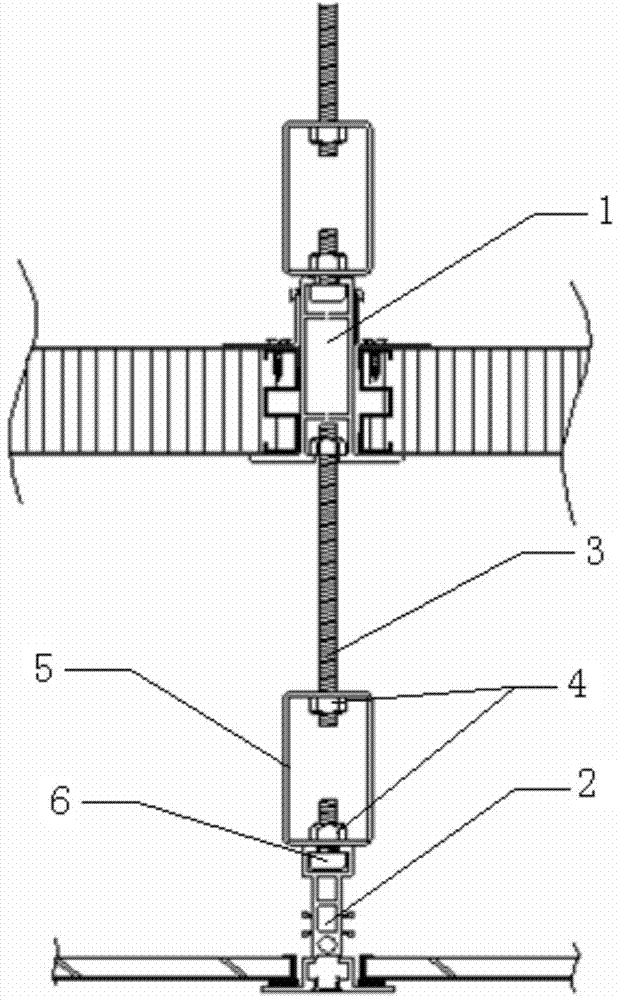

[0019] Example: refer to figure 1 , as shown in 2, a double-layer suspended ceiling assembly keel, including an upper keel 1, a lower keel 2, a screw 3, a nut 4 and a level adjuster 5, the level adjuster 5 is located between the screw 3 and the lower keel 2, the screw 3 One end is inserted into the slot at the bottom of the upper keel 1 and fixed by the nut 4, the other end of the screw 3 is connected to the top of the level adjuster 5 through the nut 4, and the bottom of the level adjuster 5 is connected to the top slot of the lower keel 2 through the bolt 6. The double-layer keel ceiling has good sound insulation and dust-proof effects. At the same time, the distance between the upper keel 1 and the lower keel 2 can be adjusted arbitrarily by adding a level adjuster 5 .

[0020] The upper keel 1 and the lower keel 2 of the present invention include a plurality of keel bodies and steel connectors, the keel bodies are connected by steel connectors, and the steel connectors i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com