High-speed hydraulic drilling rig with monomotor

A hydraulic drilling rig and a single-engine technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve problems such as high cost, heavy weight, and chains are easy to break, and achieve improved performance, high degree of automation, and increased drilling effect of depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

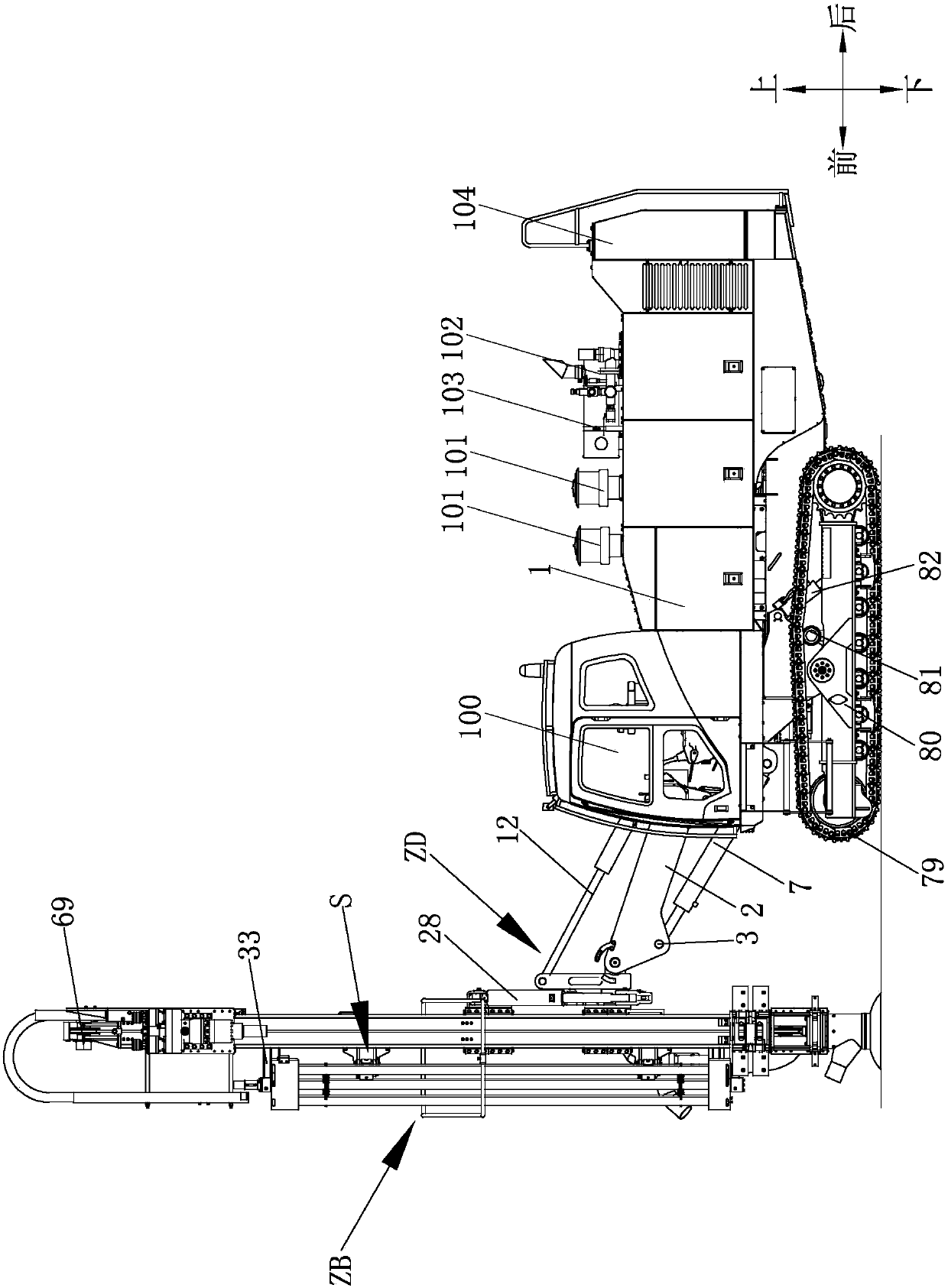

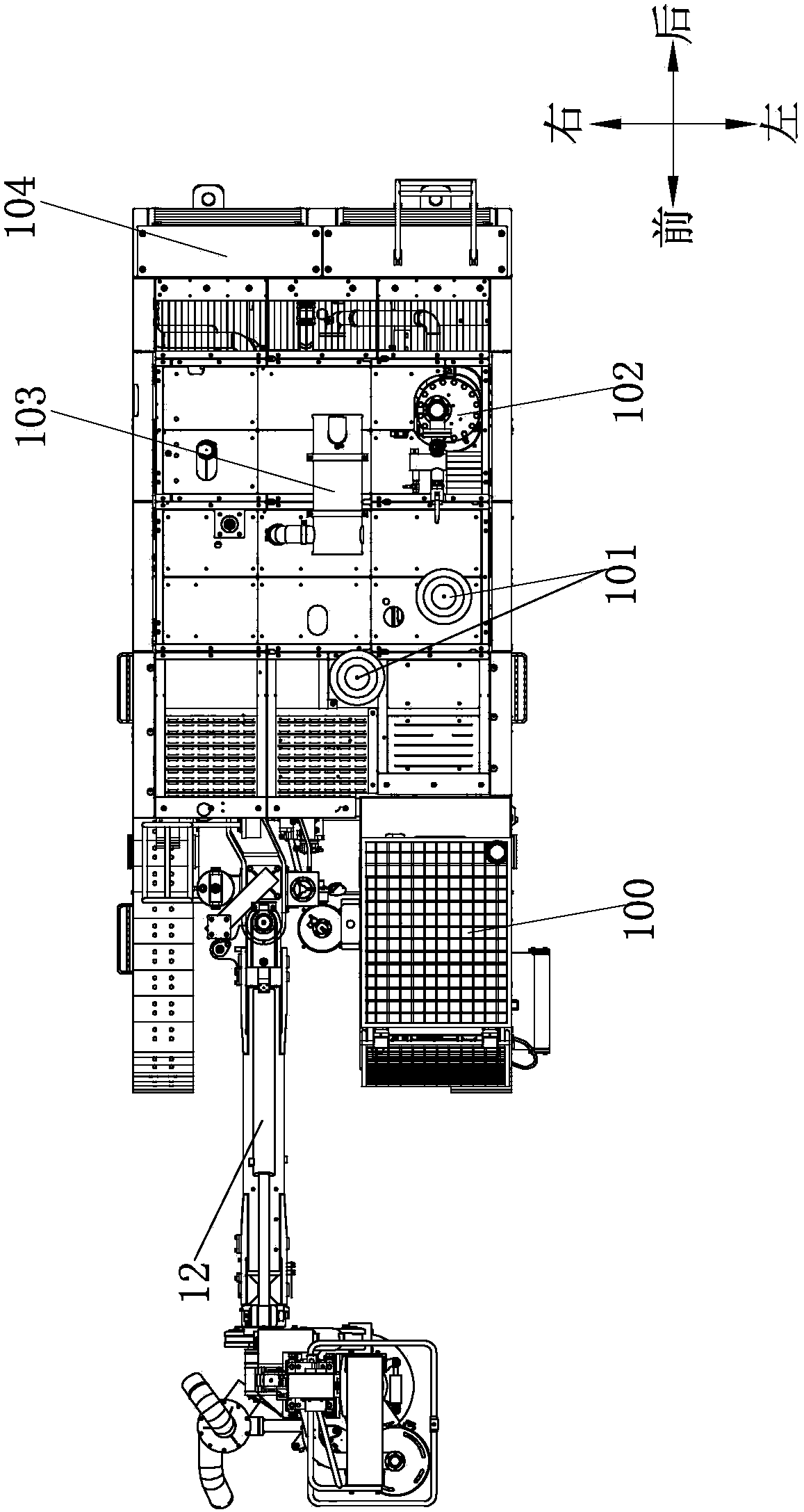

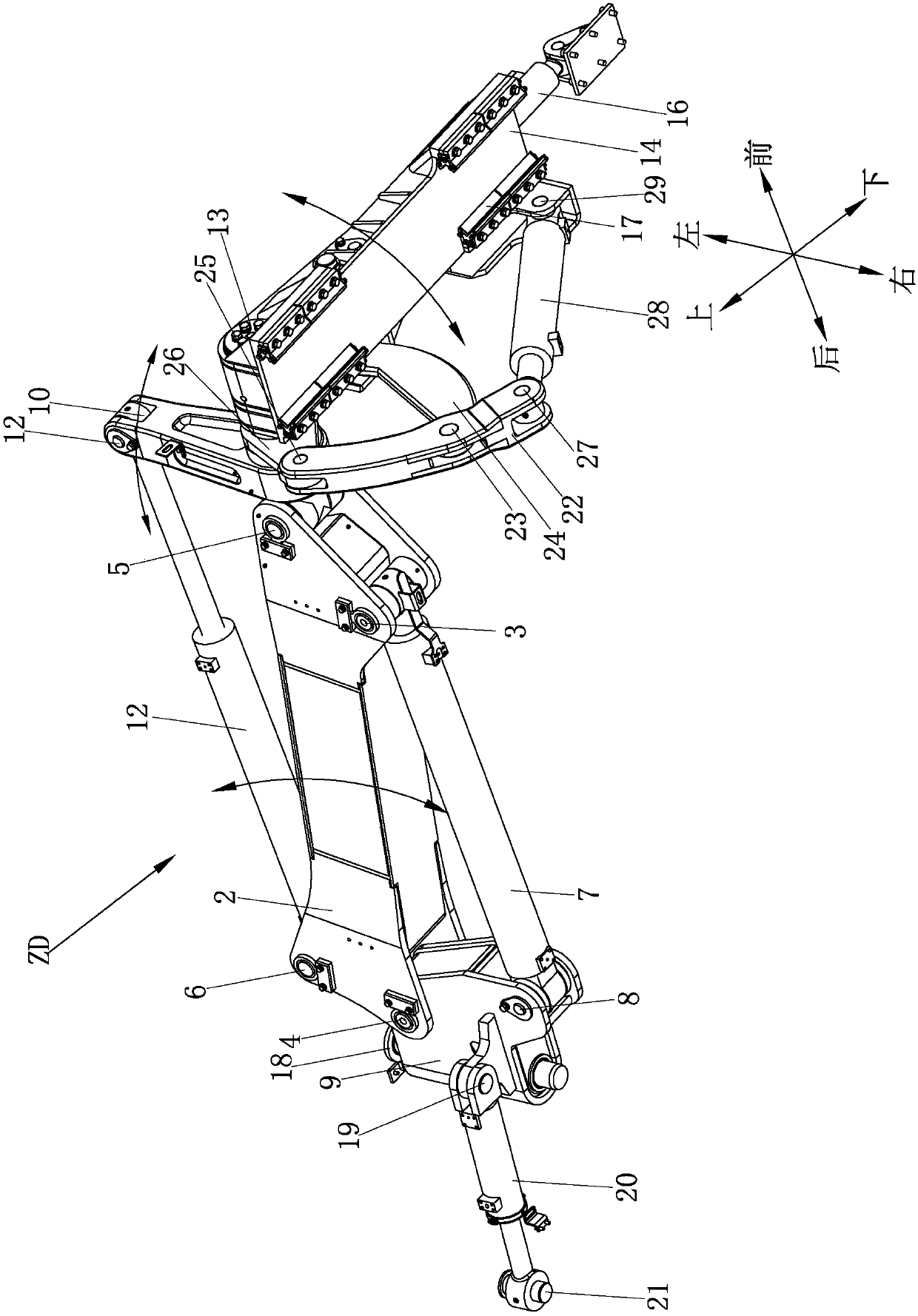

[0060] Such as Figure 1-14 As shown, a high-speed hydraulic drilling rig with a single engine is mainly composed of a car body 1, a chassis, a straight arm assembly ZD and a drill boom assembly ZB. Wherein, an engine is installed at the car body 1 rear portion, and this car body 1 is installed on the chassis, and left crawler belt traveling device and right crawler belt traveling device are arranged side by side on the chassis. And, the left end of the front side of the vehicle body 1 is a driver's cab 100, and the top of the vehicle body 1 behind the driver's cab is provided with two intake air filters 101, and the top of the vehicle body behind the two intake air filters is provided with an air intake. Compressor 102 and muffler 103, wherein the air compressor 102 is located at the left rear side of the muffler 103, and the muffler is located directly abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com