Submarine pipeline cutting robot

A technology for cutting robots and submarine pipelines, applied in metal sawing equipment, propulsion components, ship construction, etc., can solve problems such as long time-consuming and difficult, and achieve fast cutting speed, low cost, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

[0046] This kind of submarine pipeline cutting robot includes a robot carrier, an electronic control system and a hydraulic system that provide power and control for the carrier, and its uniqueness lies in:

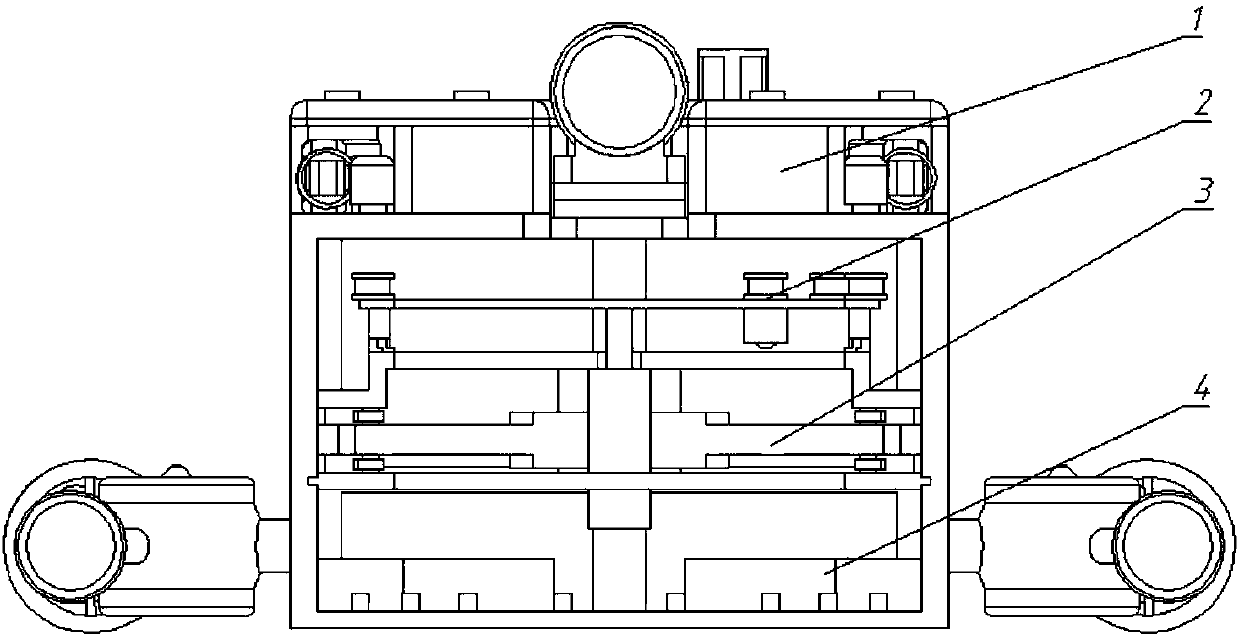

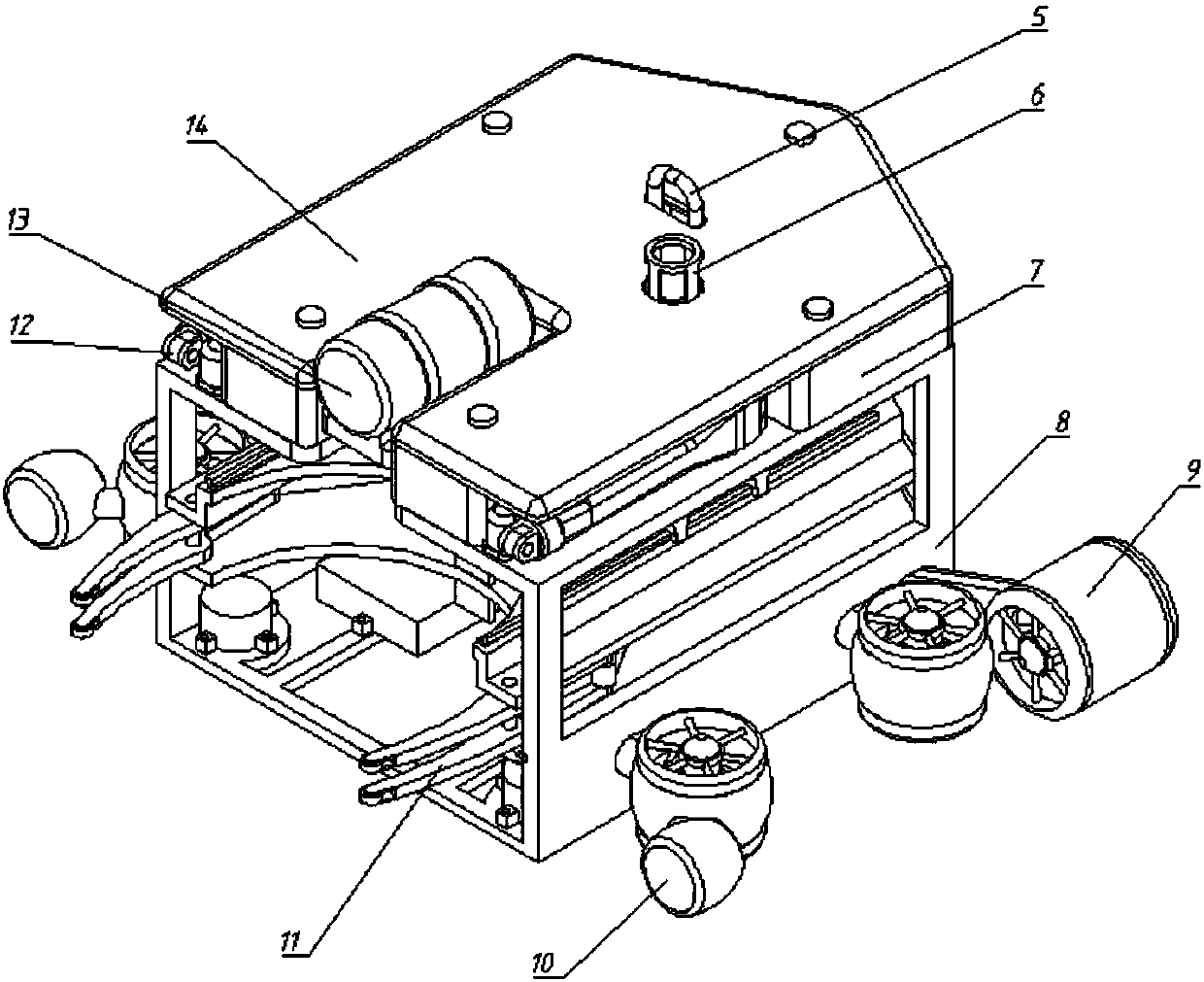

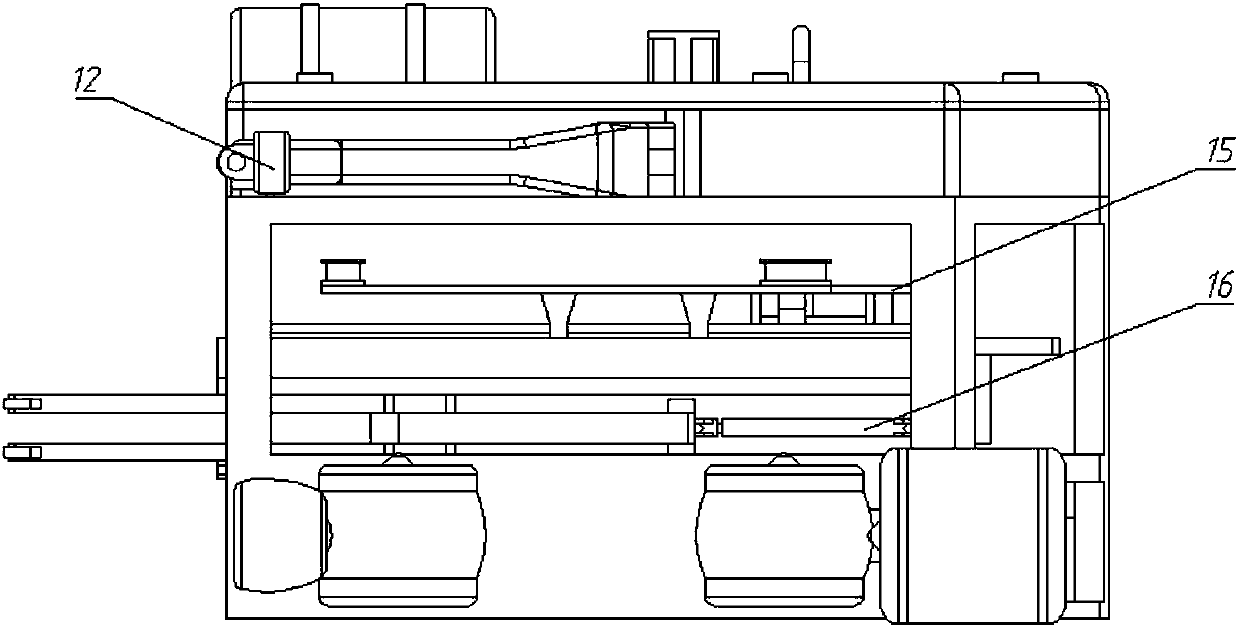

[0047] The robot carrier includes a carrier body 1 , a cutting device 2 , a pushing device 3 , and a clamping device 11 . Wherein, the carrier body 1 includes a lifting device 5 , a sonar fixing sleeve 6 , a buoyancy block 7 , a frame 8 , a lighting lamp 10 , a camera pan / tilt 12 and a top plate 14 . The buoyancy block 7 is made of machinable buoyancy material, located between the frame 8 and the top plate 14, and fixed by bolts 17; the top plate 14 is a hollow structure, which provides gaps for the buoyancy block 7 and reduces the influence of pressure on the buoyancy block; the carrier body 1 Three lighting lamps 10 are installed, one of which is located directly in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com