A high-pressure-resistant movable connection device for liquid delivery pipelines

A technology of movable connection and conveying pipeline, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, passing element, etc., it can solve the problems of lack of sealing effect, damage to rubber pad, easy generation of gap, etc., and achieve good sealing performance. , long life, stable rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

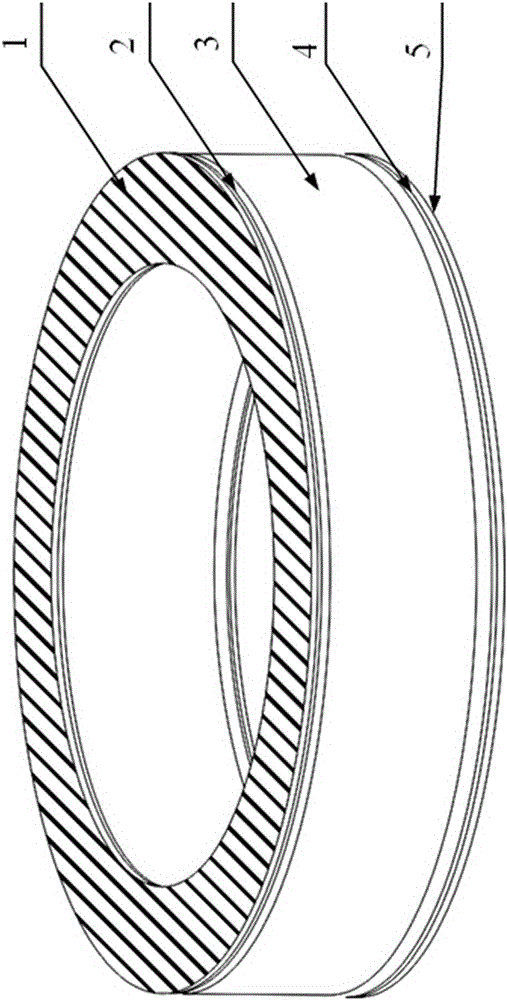

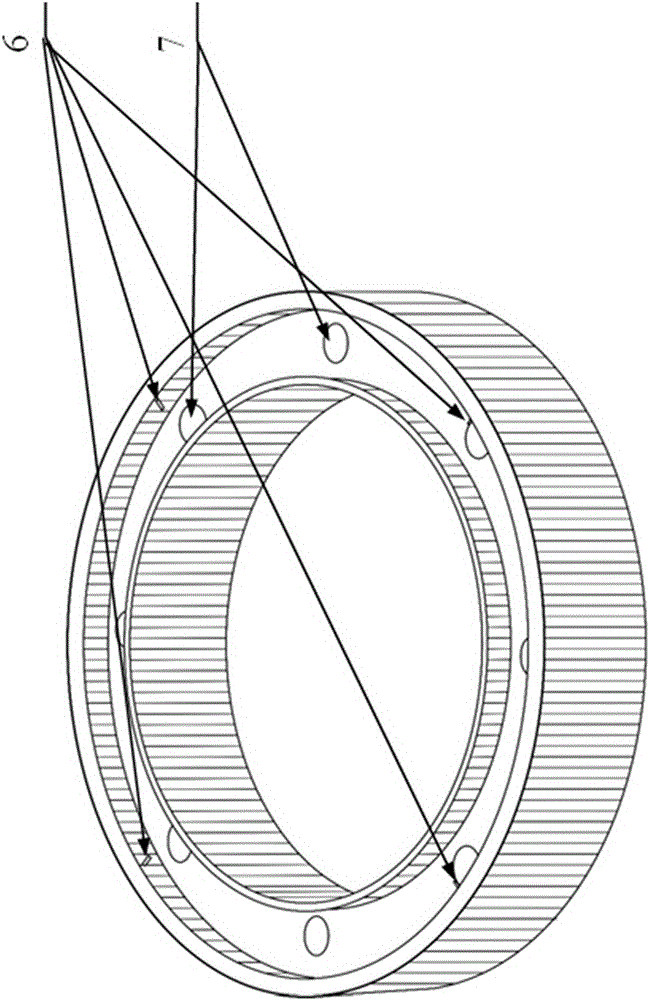

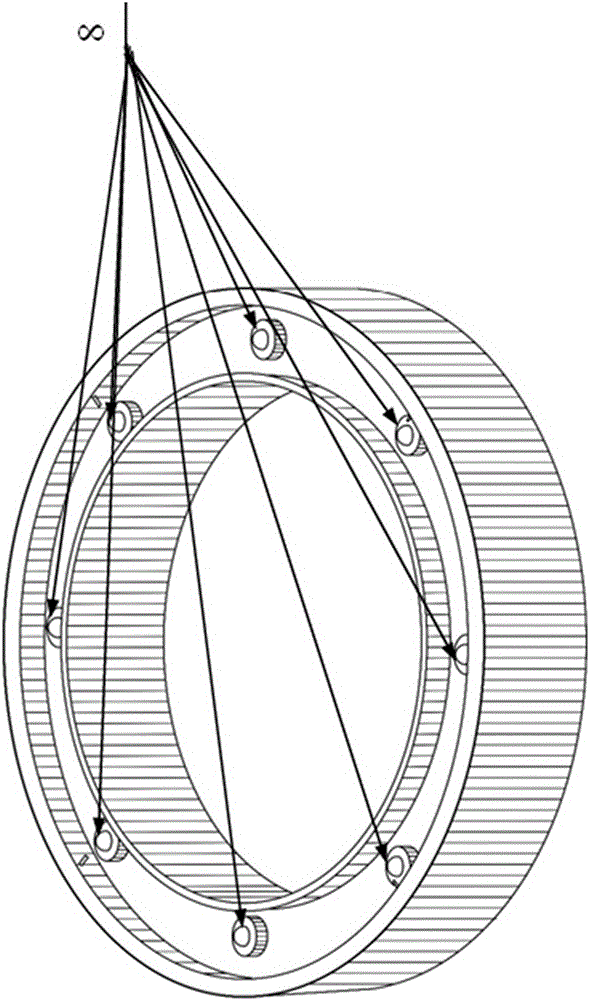

[0022] See figure 1 . A high-pressure resistant movable connection device for liquid conveying pipelines, including an integral fixed sleeve 3, two gaskets (upper rubber gasket 1, lower rubber gasket 5), two gasket brackets (upper gasket bracket 2. Lower gasket bracket 4), eight spring ball assemblies 8 (see image 3 , 5 ), the integral fixing sleeve 3 is provided with eight axial installation through holes 7 for installing the spring ball assembly in its annular part (see figure 2 ), eight spring ball assemblies 8 are respectively installed in the eight axial installation through holes 7 of the integral fixed sleeve 3 (see image 3 ). The two gasket brackets are respectively placed at the upper and lower ends of the integral fixing sleeve 3 (the upper gasket bracket 2 is on the upper side, and the lower gasket bracket 4 is below), and the ball groove 9 is provided for matching balls (see Figure 4 ) toward the integral fixing sleeve 3, and the two gaskets are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com