Scotching structure

A technology of driving rollers and roller shafts, which is applied in textiles and papermaking, fabric surface trimming, fabric elongation, etc. It can solve the problems that the quality cannot be guaranteed, the fabric is prone to wrinkles and wear, and it is not easy to wrinkle and avoid wrinkles. , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

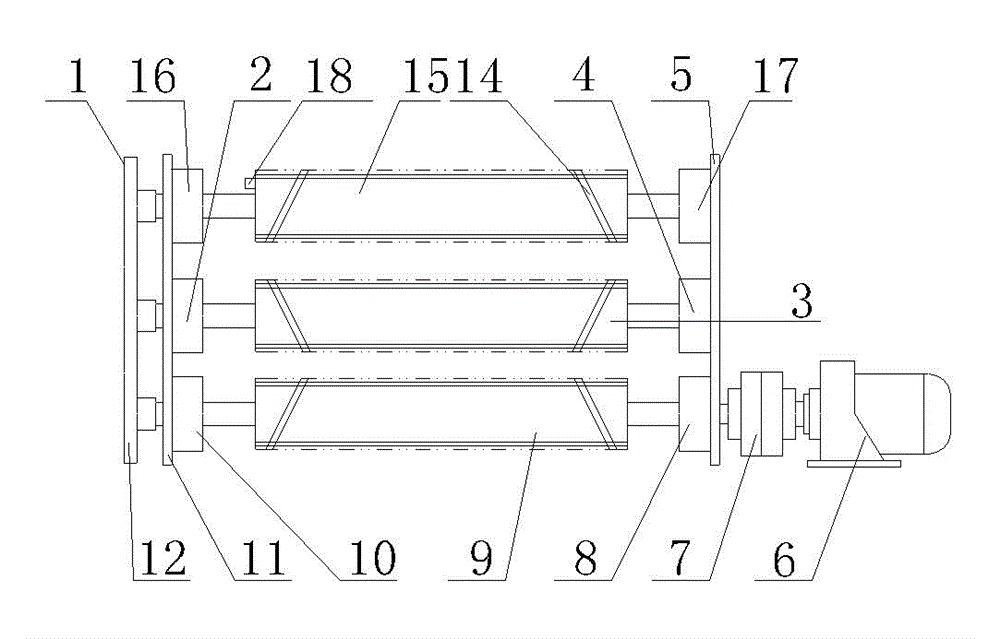

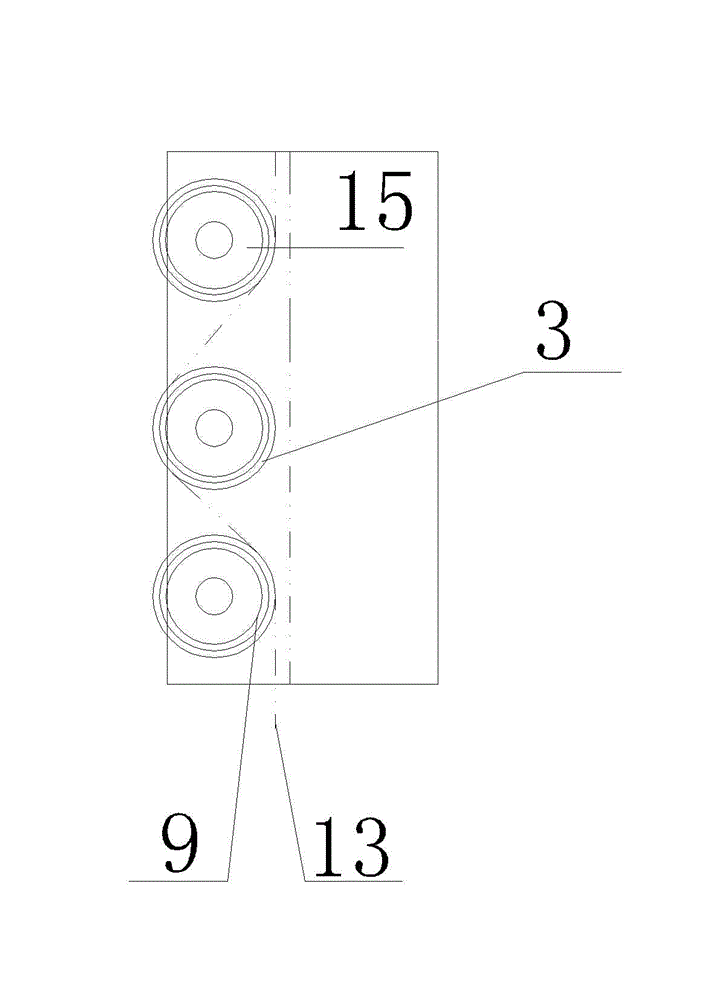

[0010] See figure 1 , figure 2 , the present invention includes a roller shaft, the roller shaft includes an induction roller shaft 15, a driving roller shaft 9, and a driven roller shaft 3, the shaft surface of the roller shaft is a threaded surface, and it also includes a stepping motor 6, and the stepping motor 6 passes through a shaft coupling The device 7 drives the driving roller shaft 9, the driving roller shaft 9 connects the driven roller shaft 3 and the induction roller shaft 15 through the meshing gear 12, 1, and the driving roller shaft 9, the driven roller shaft 3 and the induction roller shaft 15 are respectively installed on the bearing housing 8, 10 and 2, 4 and 16, 17, the induction roller shaft 15 also includes a speed sensor 18, the speed sensor 18 communicates with the stepper motor 6, the thread surface is divided into two sections and the spiral direction is opposite, the rotation of the driving roller shaft 9 When the direction ensures that the fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com