Special concrete for railway sleeper and railway sleeper poured by using concrete

A technology for railway sleepers and concrete, which is applied in the field of railway sleepers and special concrete for railway sleepers. It can solve problems such as the reduction of bearing capacity of railway sleepers, the influence of vehicle operation, and cracks on the surface of railway sleepers. It achieves enhanced compactness, enhanced bearing capacity, and improved resistance Osmotic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

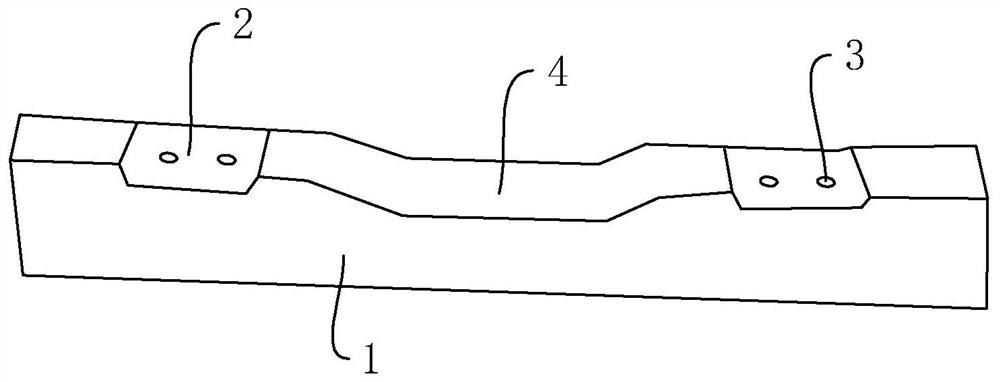

Image

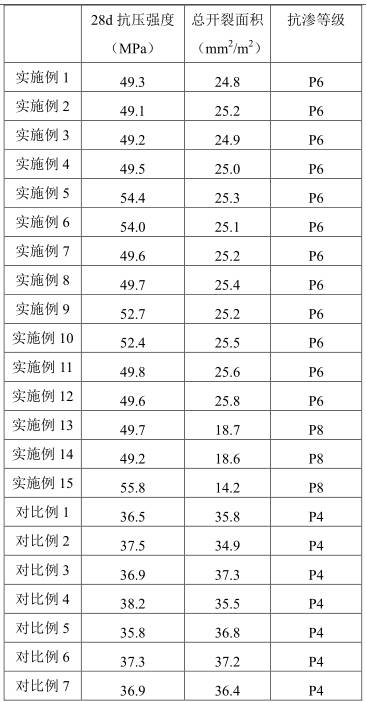

Examples

Embodiment 1-4

[0054] This embodiment discloses a special concrete for railway sleepers, which includes the following components by weight:

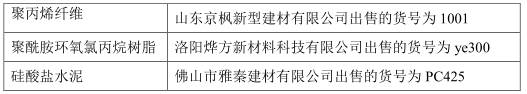

[0055] Portland cement; sand; recycled gravel; polypropylene fiber; polyamide epichlorohydrin resin; silica powder; admixture; water reducer; water.

[0056] This embodiment also discloses a method for preparing concrete for railway sleepers, comprising the following steps:

[0057] Step (1): According to the ratio in Table 2, add polypropylene fiber, polyamide epichlorohydrin resin and silicon micropowder into the stirring tank, stir at a speed of 120r / min for 20min, and mix evenly to obtain a mixture;

[0058] Step (2): While stirring, add Portland cement, sand, recycled gravel, admixtures, water reducer and water to the mixture, stir at a speed of 100r / min for 30min, and mix well to obtain concrete. Compound;

[0059] Step (3): Evenly pour the concrete mixture into the mold, and cure and shape to obtain concrete (for railway sleepers).

[0060] T...

Embodiment 5

[0065] The difference from Example 4 is that the length of the polypropylene fiber is 12mm.

Embodiment 6

[0067] The difference from Example 4 is that the length of the polypropylene fiber is 16mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com