Power cable laying device

A power cable and sliding rod technology, which is applied in the field of power cable laying devices, can solve problems such as cable surface wear, cable winding chaos, and affecting the service life of cables, and achieve the effect of ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

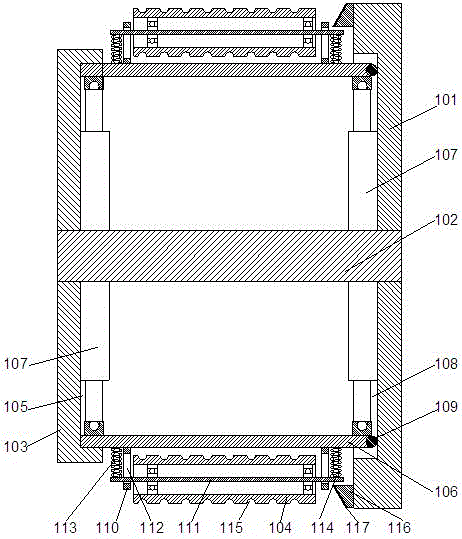

[0021] This embodiment discloses a preferred structure of a sliding rod. Preferably, two sets of beams 110 are arranged on the sliding rod 106, and the two sets of beams are symmetrically arranged on the sliding rod. Crossbar structure, the axis of the crossbeam 110 is perpendicular to the axis of the sliding rod 106, that is, the axis of each crossbar is perpendicular to the length direction of the sliding rod, and the two groups of crossbeams 110 are respectively provided with rotating shafts 111, so that the two groups of rotating shafts Parallel to each other, the rotating shafts 111 are parallel to the sliding rod 106, and the two rotating shafts 111 are symmetrically arranged on the side of the sliding rod 106 away from the central axis 102 respectively. By setting two sets of rotating shafts, the When the cable touches the vertical roller, when it turns under the support of the vertical roller, it will not be folded due to sudden turning, reducing the damage of the cable...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, in order to improve the stability of the overall structure and prevent the cables from being broken due to instantaneous force, preferably, a through groove 112 is provided on the beam 110, so that the through groove The length direction is parallel to the length direction of the beam, and the upper and lower ends of the rotating shaft 111 pass through the corresponding through grooves 112 respectively, so that the rotating shaft is in a relatively vertical state under normal conditions, that is, parallel to the sliding rod. 106 is provided with an upper buffer spring group 113 and a lower buffer spring group 114. Using the spring structure, when the cable contacts the vertical roller, the instantaneous force on the cable can be buffered. One end of the upper buffer spring group 113 is fixed Connected to the upper end of the rotating shaft 111, the other end of the upper buffer spring group 113 is fixedly connected to the...

Embodiment 3

[0027]In this embodiment, in order to facilitate cable laying, the cables are stacked in a regular structure. Preferably, wiring grooves 115 arranged at equal intervals are arranged on the outer wall of the vertical roller 104 . During the winding process of Xialan, the cable can be wound in the wiring groove on the vertical roller, so that it can be kept stable, and it is convenient for the staff to control the length of the cable laying allowance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com