Purification method of dry-type iron oxide powder solid

A technology of iron oxide powder and purification method, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of poor consistency, large fluctuation, and can not meet the requirements of ultra-high-purity iron oxide powder, and achieve chemical properties. The effect of improving indicators and physical performance indicators and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

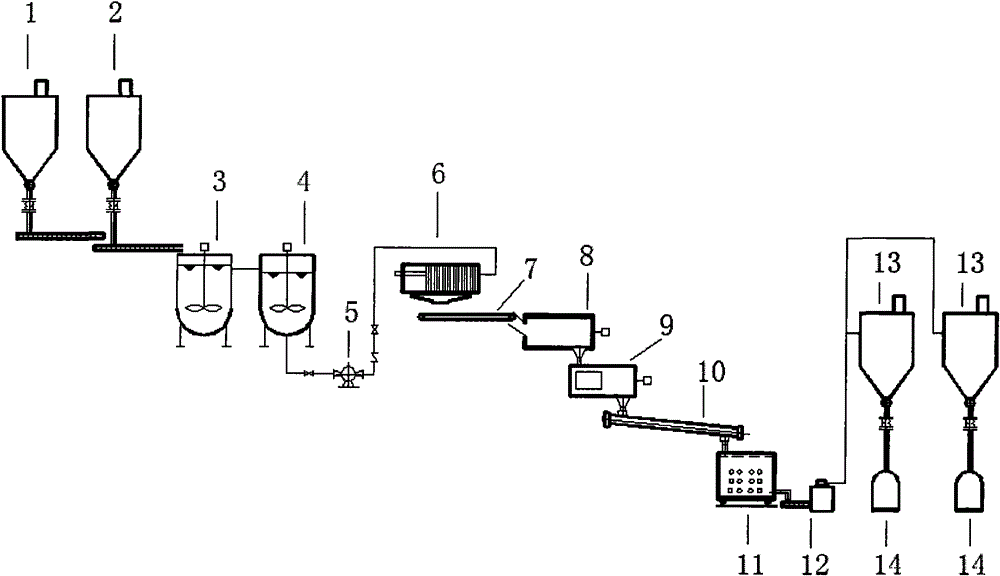

Image

Examples

Embodiment 1

[0030] The process flow is as mentioned above, wherein the weight ratio of iron oxide powder and washing water is 1:3, the stirring speed is 120rpm, the filtrate in the first 5 minutes of pressure filtration needs to be refluxed, the pre-drying temperature is 250°C, and the drying temperature is 300°C.

Embodiment 2

[0032] The process flow is as mentioned above, wherein the weight ratio of iron oxide powder and washing water is 1:5, the stirring speed is 150rpm, the filtrate in the first 15 minutes of pressure filtration needs to be refluxed, the pre-drying temperature is 300°C, and the drying temperature is 400°C.

Embodiment 3

[0034] The technological process is as mentioned above, wherein the weight ratio of iron oxide powder and washing water is 1:8, the stirring speed is 180rpm, the filtrate in the early stage of press filtration for 20 minutes needs to be refluxed, the pre-drying temperature is 350°C, and the drying temperature is 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com