Preparation method of environment-friendly type melamine-based foamed plastic

A foamed plastic and melamine-based technology, which is applied in the field of preparation of environment-friendly melamine-based foamed plastics, can solve problems such as hindering the application range of products, affecting people's physical and mental health, restricting market application fields, etc., achieving non-volatile, convenient storage, smooth response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

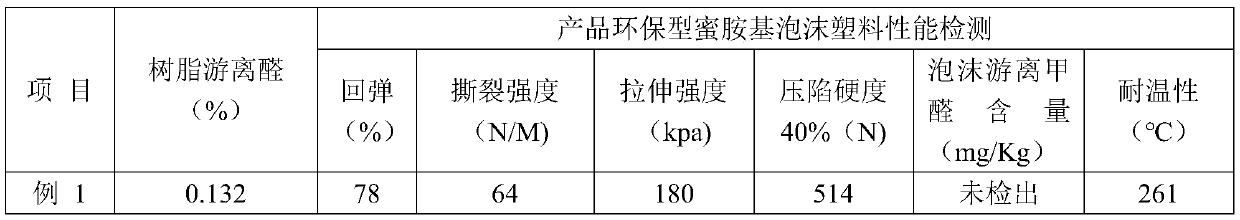

Embodiment 1

[0041] The preparation method of the environment-friendly melamine-based foam plastic of the present invention, the detailed steps of the preparation method are as follows:

[0042] (1) Preparation of expandable low-formaldehyde melamine-based resin:

[0043] a, with melamine, paraformaldehyde and water as main raw materials; expressed in weight kg, the addition of three main raw materials is respectively melamine 600Kg, paraformaldehyde 328.6Kg and desalted water 310Kg;

[0044] B, take by weighing melamine, paraformaldehyde and water according to the addition of three kinds of main raw materials described in step a, add three kinds of raw materials that take by weighing in the reactor and stir evenly, then add modified monomer benzomelamine 3Kg, then Add a sodium hydroxide solution with a mass percentage concentration of 20% to adjust the pH value to 8-9; when the steam is heated until the temperature of the reaction solution reaches 90°C, reduce the amount of steam introduc...

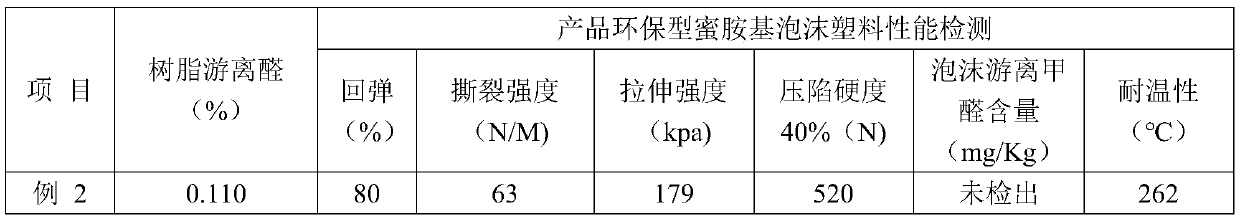

Embodiment 2

[0058] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0059] The preparation method of the environment-friendly melamine-based foamed plastic of the present invention is basically the same as that of Example 1, except that:

[0060] (1) Preparation of expandable low-formaldehyde melamine-based resin:

[0061] a, represented by weight kg, the addition of three main raw materials is respectively melamine 600Kg, paraformaldehyde 357.1Kg and desalted water 319Kg;

[0062] b. Then use a sodium hydroxide solution with a mass percentage concentration of 25% to adjust the pH value to 8-9, then add 6Kg of modified monomer ultrafine polyimide resin powder; Reduce the amount of steam input and react at a constant temperature for 2.5 hours, close the steam inlet valve, and the reaction is over;

[0063] c. Then add 6.4Kg of aldehyde-removing functional monomer 1,3-dimethyl-2-imidazolidinone;

[0064] (2) Preparation of mixing aids:

[0065] Add 60Kg of 40% sodi...

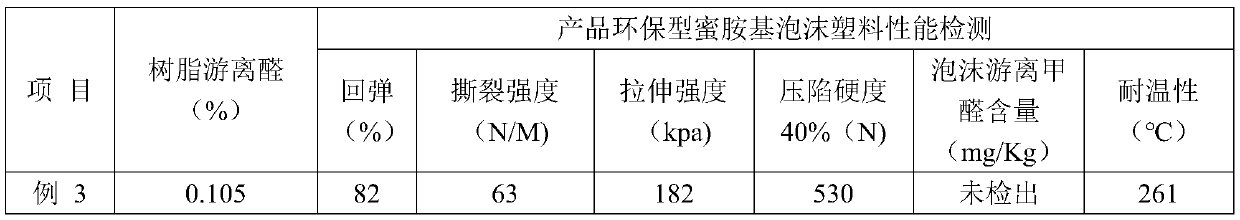

Embodiment 3

[0074] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0075] The preparation method of the environment-friendly melamine-based foamed plastic of the present invention is basically the same as that of Example 1, except that:

[0076] (1) Preparation of expandable low-formaldehyde melamine-based resin:

[0077] a, represented by weight kg, the addition of three main raw materials is respectively 600Kg of melamine, 400Kg of paraformaldehyde and 340Kg of desalted water;

[0078] b. Then use a sodium hydroxide solution with a concentration of 25% by mass to adjust the pH value to 8-9, then add 9Kg of modified monomer tris-(2-hydroxyethyl)isocyanate; , turn down the amount of steam into the constant temperature reaction for 2 hours, close the steam inlet valve, the reaction is over;

[0079] c, then add 13.4Kg of aldehyde-removing functional monomer melamine,

[0080] (2) Preparation of mixing aids:

[0081] Add 64Kg of 25% sodium alkylnaphthalene sulfona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com