Patents

Literature

64results about How to "Best dosage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress-resistant feed for aquatic products and feed additive

InactiveCN106721516AImprove immunityGrowth inhibitionFood processingClimate change adaptationFood additiveAquatic animal

The invention provides a stress-resistant feed for aquatic products, and a feed additive. The stress-resistant feed additive for aquatic products is mainly prepared from the following components in percentage by weight: 3-20% of a butyric acid derivative, 1-10% of marine rhodotorula, 0.2-5% of taurine, 5-20cfu / g of probiotics, 1-20% of a traditional Chinese medicine extract, 1-10% of complex vitamins and the balance of other auxiliary materials. The additive disclosed by the invention can notably improve the stress response resistance of aquatic animals, besides, the functions of the additive are diversified, the tolerance of the aquatic animals to various adverse environments of hypoxia, transportation and hyposaline, the adverse environment of being away from water and the like can be enhanced, and the growth of the aquatic animals can also be promoted.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

Special flavor codfish caviar and making method thereof

The invention relates to a special flavor codfish caviar formula and a making process thereof. Caviar is prepared from the following raw materials: fresh codfish roe, common salt, white granulated sugar, monosodium glutamate, cooking wine, garlic powder, ginger powder, sesame oil, starch, curry and milk. The special flavor codfish caviar formula is characterized by comprising the following raw materials in parts by weight: 100 parts of codfish roe, 3-4 parts of common salt, 1-2 parts of sugar, 0.1-0.2 part of monosodium glutamate, 4-5 parts of cooking wine, 0.5-0.7 part of garlic powder, 0.5-0.7 part of ginger powder, 4-5 parts of starch, 3-3.5 parts of sesame oil, 0.2-0.4 part of curry powder and 10-12 parts of milk. The making process of the codfish roe comprises the following steps of cleaning the fresh roe, removing films and further sequentially performing pulping, filtration, picking, seasoning and stewing. The special flavor codfish caviar formula and the making process thereof, provided by the invention have the advantages of simple process, low cost, strong operability, special flavor and richness in nutrition of codfish caviar.

Owner:SHANDONG YANTAI AGRI SCHOOL

Additive and feed capable of improving stress response resistance of prawns

InactiveCN106551187AImprove toleranceGood synergyAnimal feeding stuffAccessory food factorsBiotechnologyYeast

The invention provides an additive and a feed capable of improving stress response resistance of prawns. The additive capable of improving the stress response resistance of prawns is mainly prepared from the following components in parts by weight: 2-71 parts of composite vitamins, 0.5-20 parts of amino acids, 0.5-20 parts of taurine, 0.5-20 parts of cupric glycinate, 1-30 parts of zinc methionine, 10-300 parts of composite microbes, 50-500 parts of butyric acid derivatives, 10-100 parts of a horseradish tree extract and 20-400 parts of a yeast tissue / extract. The additive disclosed by the invention can significantly improve the stress response resistance of the prawns and particularly improve the tolerance of the prawns to external stimulus of temperature, salinity, being away from water, high PH and the like.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

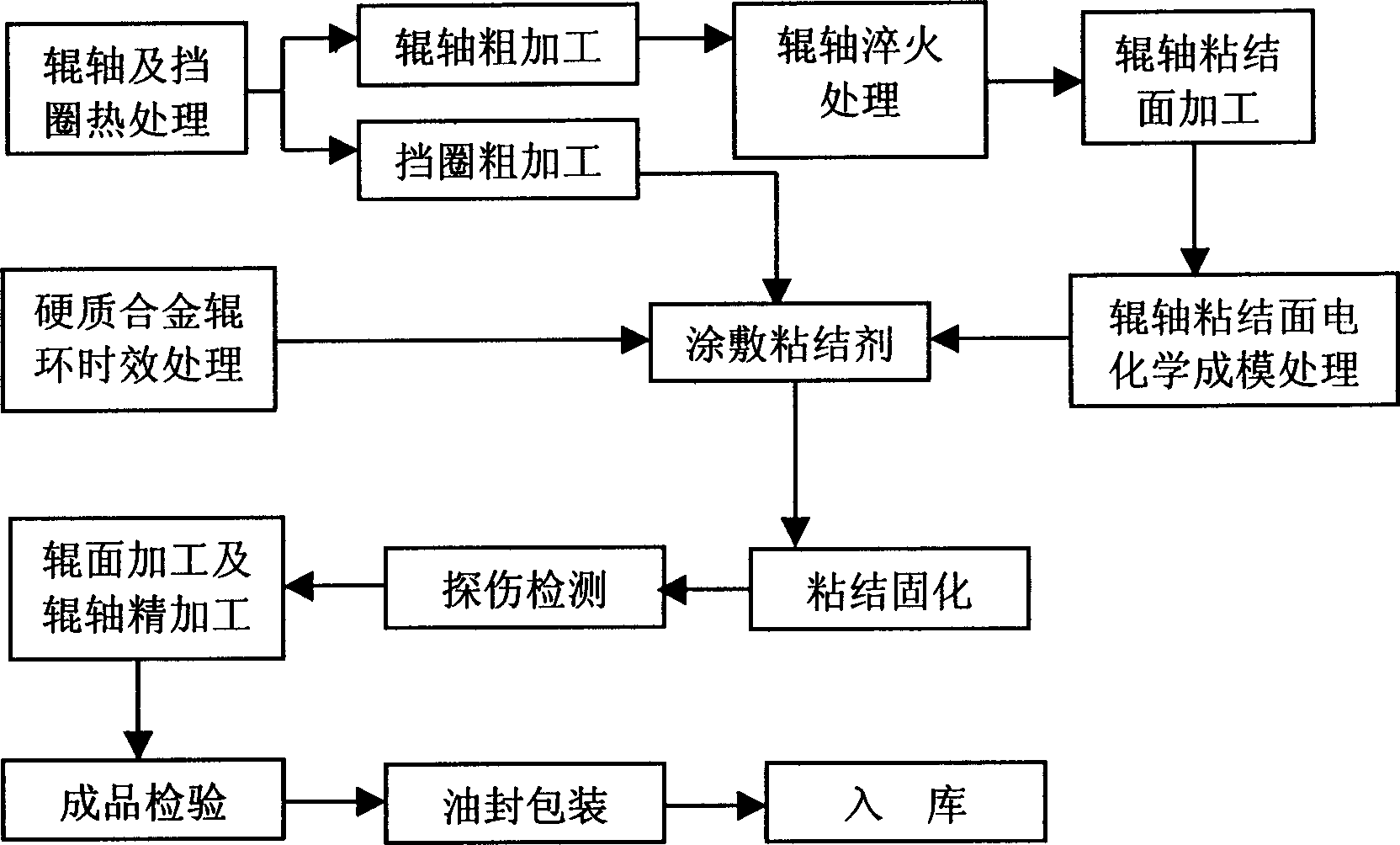

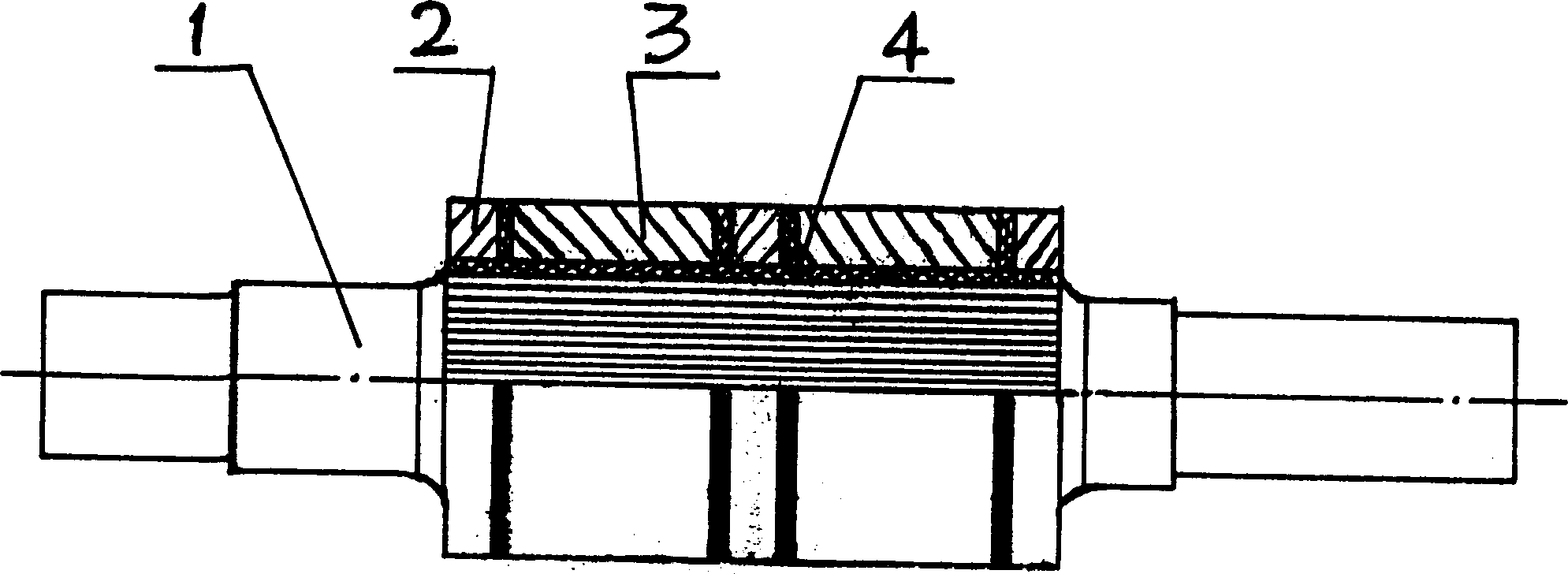

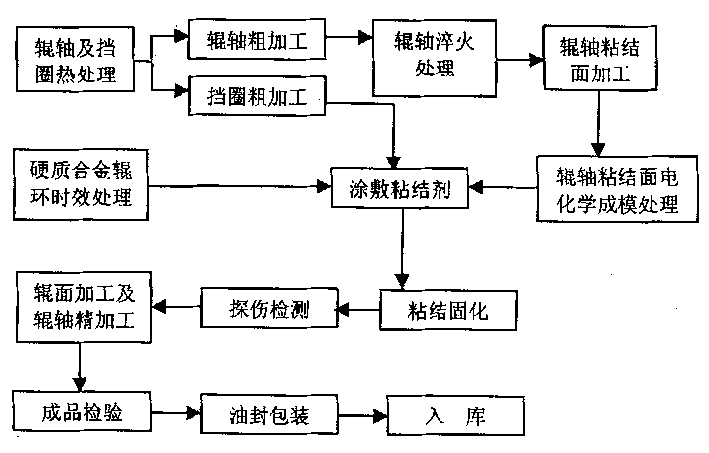

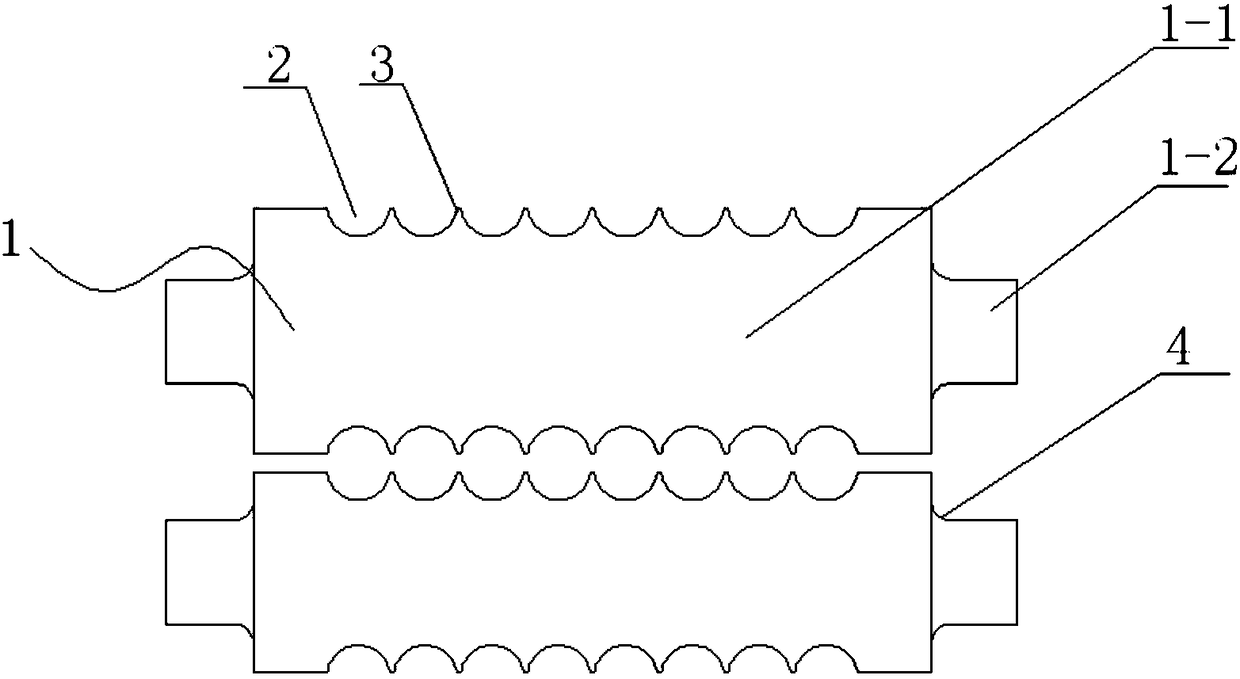

Making process of combined hard alloy roll

InactiveCN1389320ABest dosageEasy to useRollsMetal rolling arrangementsAlloy compositeHigh intensity

The production process of hard alloy composite roller includes: making roll shaft, retainer ring forge blank and hard alloy roll collar respectively undergo the processes of heat treatment and ageing treatment, rough machining roll shaft and retainer ring forge blank, quenching roll shaft and working cohesive surface, then making the cohesive surface of roll shaft undergo the process of electrochemical film-forming treatment, and respectively applying high-strength high-temp. resistant adhesive agent mixed with ultrafine tungsten carbide powder to the cohesive surface of roll shaft and inner and side surfaces of hard alloy roll collar and retainer ring, adhering and solidifying, making defect detection, fine finishing roll surfaces of roll shaft and roll collar to obtain accepted composite roll, oil sealing, packaging and putting in storage.

Owner:ZIGONG CEMENTED CARBIDE CORP

Aluminum alloy material special for die-casting aluminum alloy heat radiator and preparation method of aluminum alloy material

The invention relates to an aluminum alloy material special for a die-casting aluminum alloy heat radiator. The material is prepared from, by mass percent, 9.0%-9.4% of Si, 0.5%-0.75% of Cu, 0.35%-0.42% of Mg, 0.1%-0.25% of Mn, 0.01%-0.023% of Sn, 0.03%-0.05% of Ni, 0.07%-0.1% of Ti, 0.9%-1.2% of Zn, 0.9%-1.0% of Fe, 0.03%-0.04% of Pb, 0.0025%-0.003% of Hg, 0.001%-0.0015% of Cd, 0.002%-0.025% of the rare earth element RE, 0.15%-0.20% of Zr and the balance Al. According to the technical scheme, the contents of silicon, magnesium, iron, copper and zinc in an aluminum alloy are optimized, a deep-cavity thin-wall die-casting piece of the aluminum alloy in the heat radiator is easy to form, sticky molds are reduced, and the corrosion resisting property is enhanced; and the rare earth element and the zirconium element are added in the aluminum alloy, harmful elements and gas are removed, molten aluminum is purified, and the strength, plasticity and pressure resistance of the aluminum alloy are improved.

Owner:ZHEJIANG RONGRONG IND

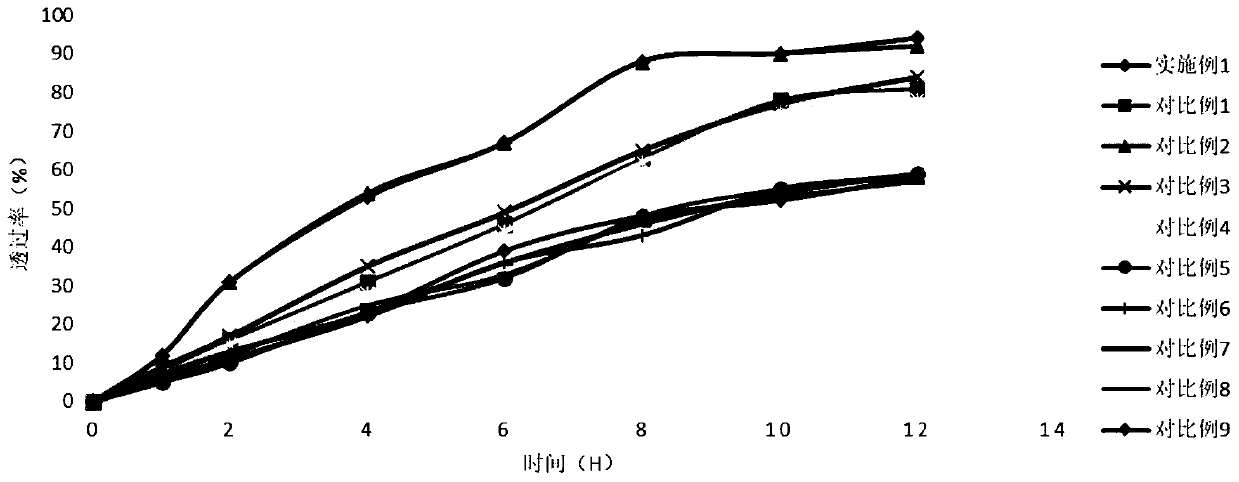

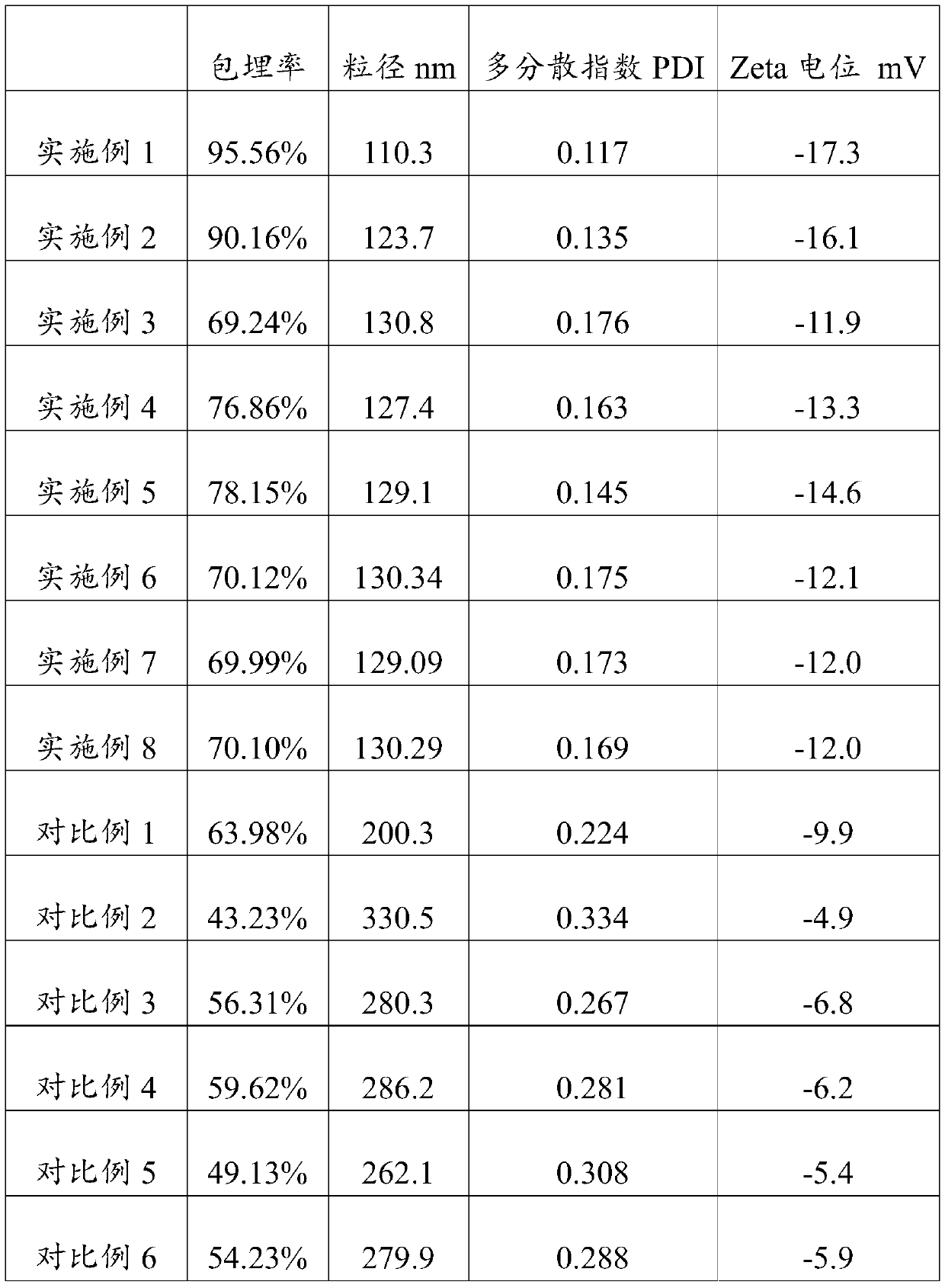

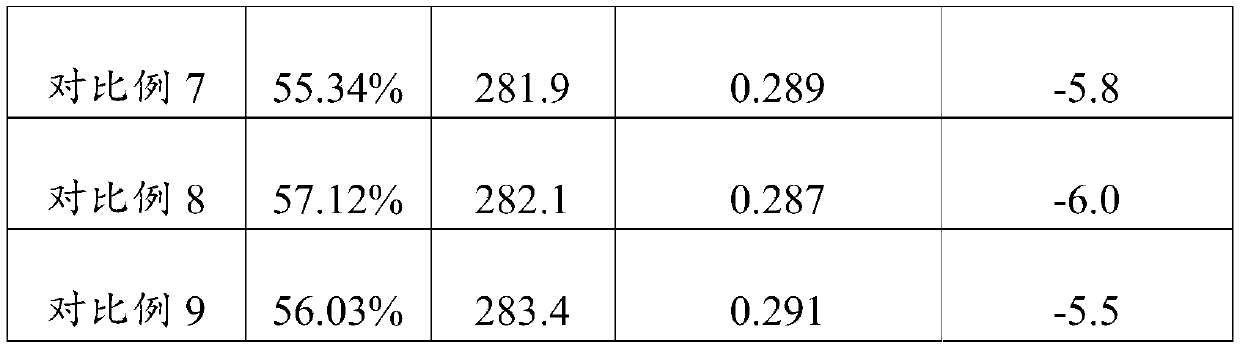

Anti-aging nano composition as well as preparation method and application thereof

ActiveCN111467284AGood targeting and transdermal absorptionReduce usageCosmetic preparationsToilet preparationsAqueous solubilityTransdermal absorption

The invention discloses an anti-aging nano composition as well as a preparation method and application thereof. The nano composition comprises the following components in percentage by mass: 0.1 to 15percent of a fat-soluble anti-aging active ingredient, 0.1 to 20 percent of a water-soluble anti-aging active ingredient, 1 to 15 percent of an emulsifier, 3 to 30 percent of a co-emulsifier and thebalance of deionized water. According to the anti-aging nano composition, in combination with the skin aging physiological structure phenotype and the skin physiological structure change caused by external environment factors, aging resistance is carried out from multiple paths, and the anti-aging nano composition has more comprehensive and effective internal and external effects and adapts to aging caused by different mechanisms; through the use of a nanostructure and the reasonable proportion of the components of the nano composition, while the nano composition has good targeting and transdermal absorption effects, the solubility and stability of the components are improved, the usage amount of the functional components is reduced, the cost is reduced, and a more comprehensive and effective anti-aging product is provided for consumers.

Owner:泉后(广州)生物科技研究院有限公司

Low-ultraviolet energy curing vacuum-spraying UV coating and preparation method thereof

ActiveCN105694678AReduce shrinkage stressGood adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterUrethane acrylate

The invention discloses low-ultraviolet energy curing vacuum-spraying UV coating and a preparation method thereof. The low-ultraviolet energy curing vacuum-sprarying UV coating is made of, by weight, 26-35% of modified low-viscosity high-functionality epoxy acrylate, 10-25% of modified high-functionality polyester acrylate, 8-12% of special modified polyurethane acrylate, 25-40% of TPGDA, 3-7% of HEMA, 0.3-0.8% of wetting dispersant, 5-10% of transparent filler, 4-8% of photoinitiator, 0.3-0.5% of leveling agent, and 0.1-0.3% of other auxiliaries. Compared with common like coatings, the vacuum-spraying UV coating has the advantages that ultraviolet energy required for coating curing is greatly reduced, and energy is saved and effectively used. In addition, possibility to cause quality defect of the backlight side of special-shaped workpieces is decreased. The vacuum-spraying UV coating has the advantages of excellent coating strength and transient leveling property.

Owner:HUNAN JINHAI SCI & TECH

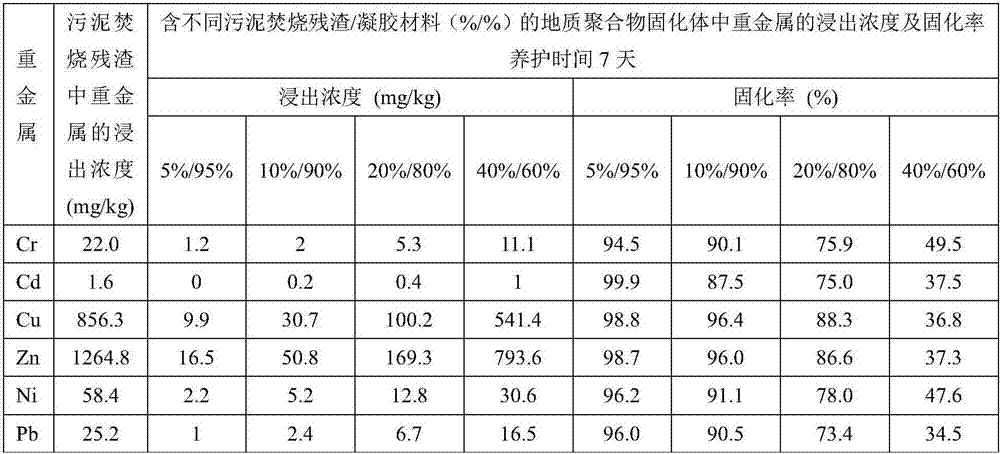

Method for efficiently immobilizing heavy metals in sludge incineration residues by preparing geopolymer

The invention belongs to the field of resources and environments, and in particular relates to a method for efficiently immobilizing heavy metals in sludge incineration residues by preparing a geopolymer. By adjusting the ratio of different sludge incineration residues to a gel material, namely metakaolin, an optimal sludge incineration residue addition amount (less than or equal to 10%) capable of efficiently immobilizing heavy metals is achieved, and by using the immobilizing method provided by the invention, the optimal immobilization rate of Cu and Zn are up to 95%, and the immobilization rates of Cr, Ni and Pb are all greater than 90%. By adopting the method, a technical support is provided for efficient immobilization on heavy metals in sludge incineration residues, and a base is made for resource utilization of the sludge incineration residues.

Owner:SHENZHEN UNIV

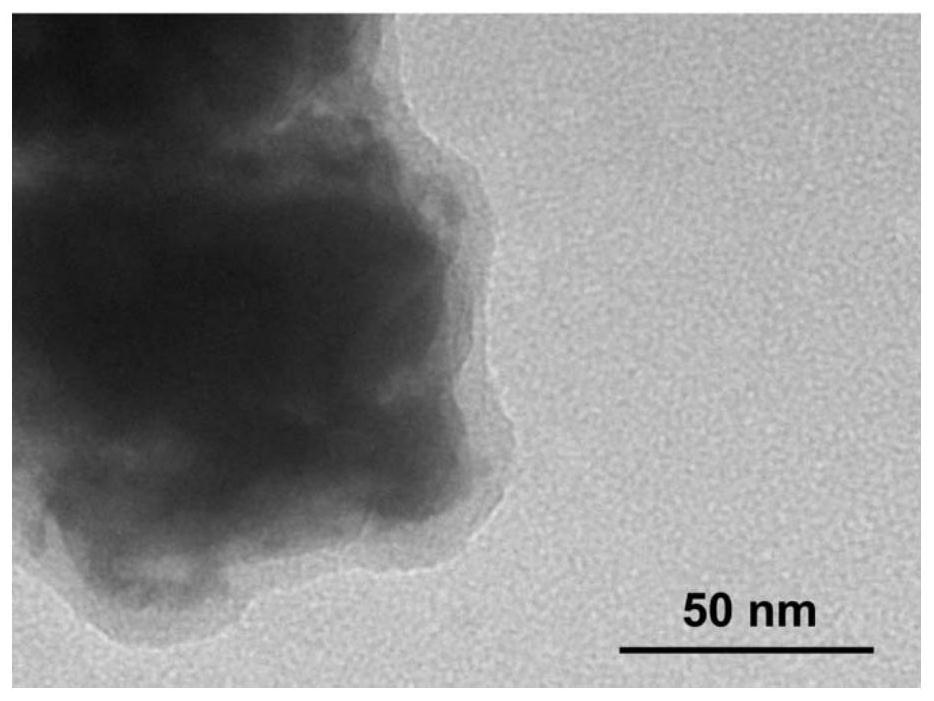

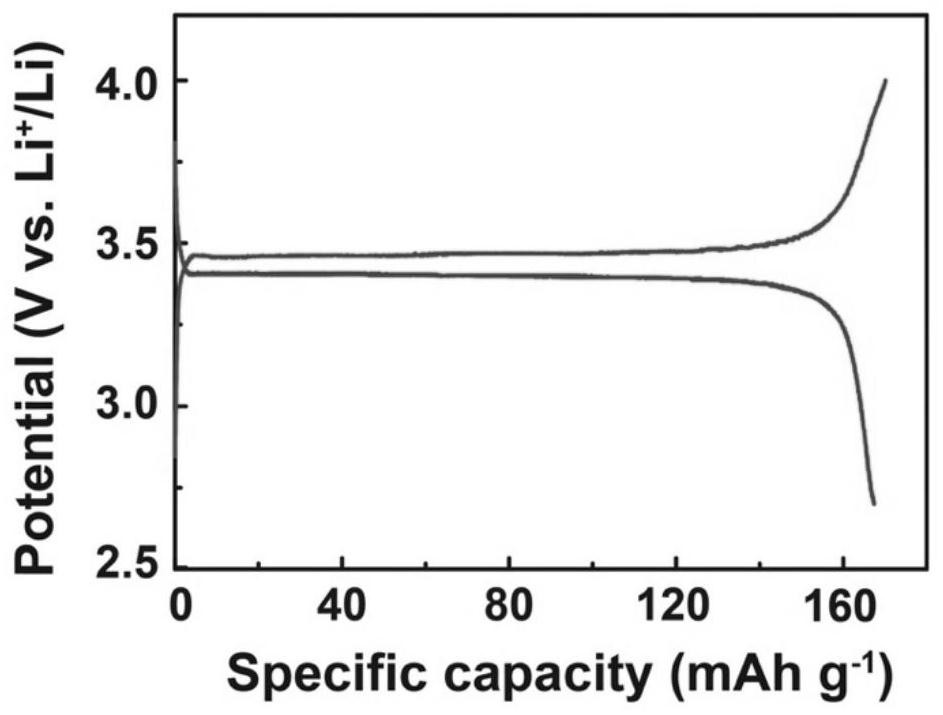

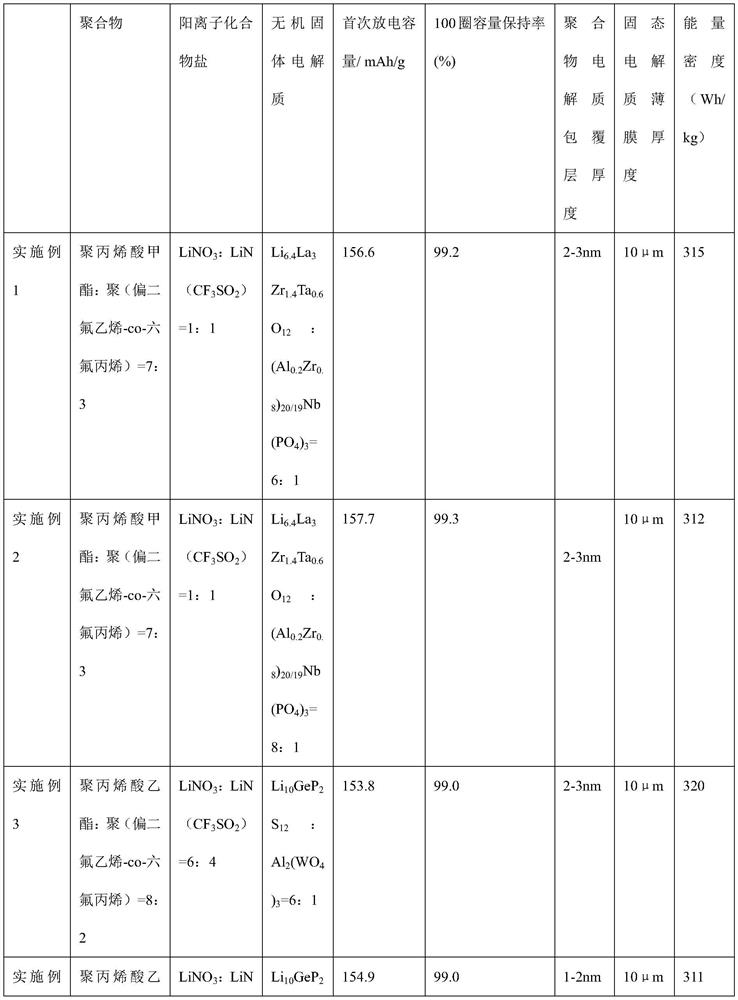

Composite solid electrolyte, preparation method thereof and application thereof in solid-state secondary battery

ActiveCN112234249ASimple manufacturing processHave mechanical strengthSolid electrolytesFinal product manufactureElectrically conductiveIn situ polymerization

The invention discloses a conductive coated composite solid electrolyte, a preparation method thereof and an application of the conductive coated composite solid electrolyte in a solid-state secondarybattery. The composite solid electrolyte is composed of inorganic solid electrolyte particles and a polymer electrolyte coating layer formed on the surfaces of the inorganic solid electrolyte particles. The preparation method of the composite solid electrolyte comprises the following steps of uniformly mixing the polymer / polymer monomer, the cationic compound salt and the inorganic solid electrolyte powder according to a certain ratio to obtain a precursor solution, and adding an initiator to initiate in-situ polymerization of the polymer monomer on the surfaces of solid electrolyte particles, or adding a precipitant to separate out the polymer on the surfaces of the solid electrolyte particles, thereby preparing the composite solid electrolyte. Furthermore, the prepared composite solid electrolyte and a solvent are mixed according to a certain proportion to obtain uniform and stable slurry, and a solid electrolyte film is prepared on the surface of a base material or an electrode byusing a tape-casting coating process and is used for producing a solid-state secondary battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

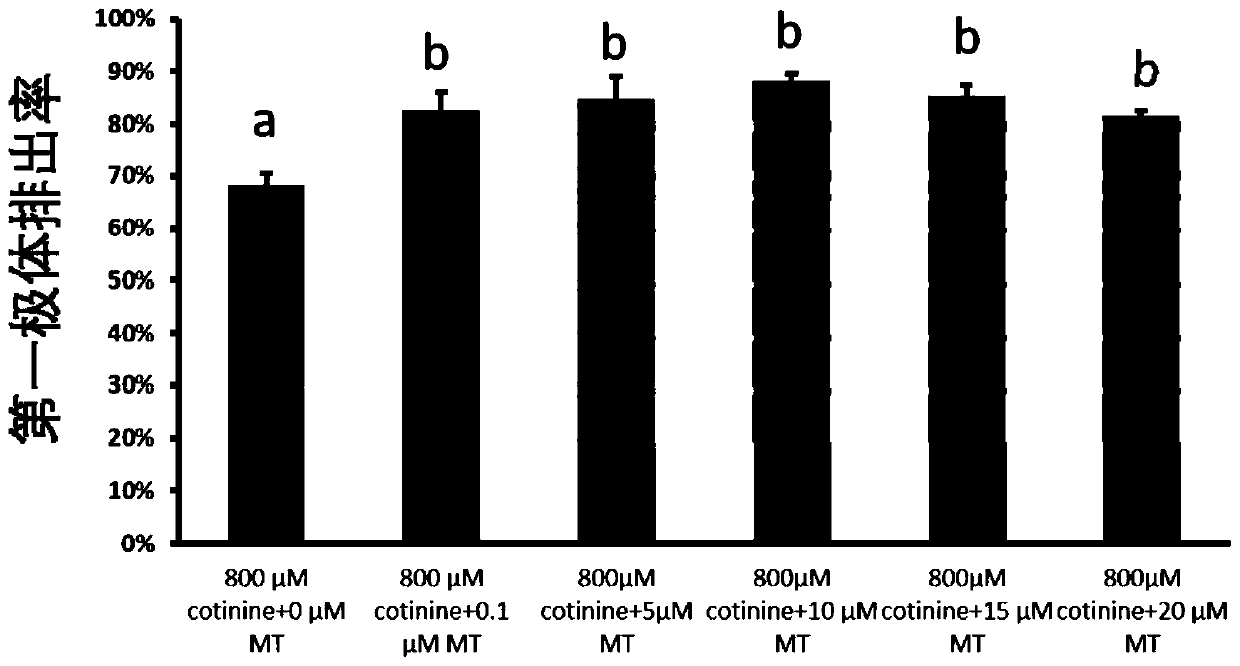

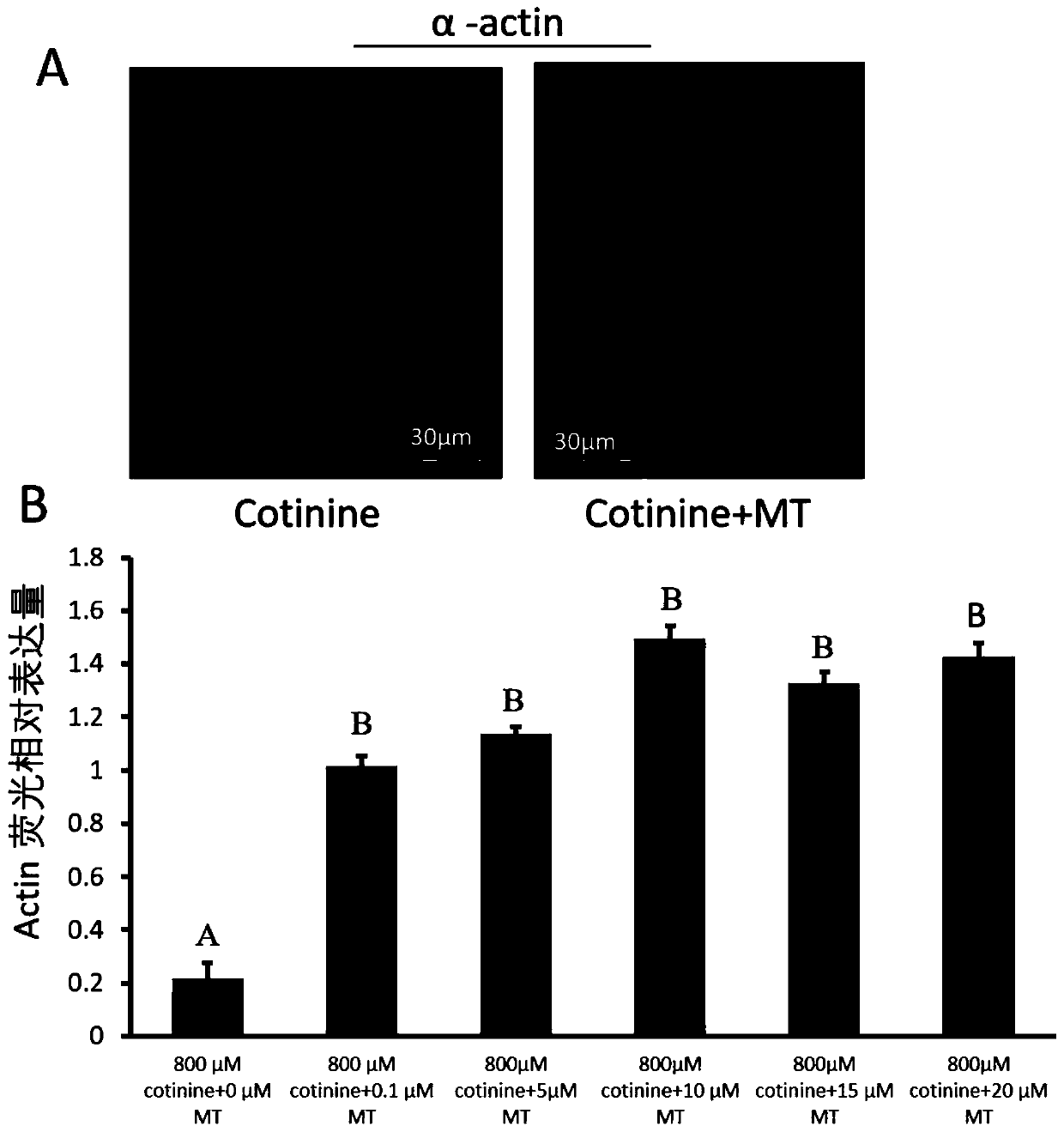

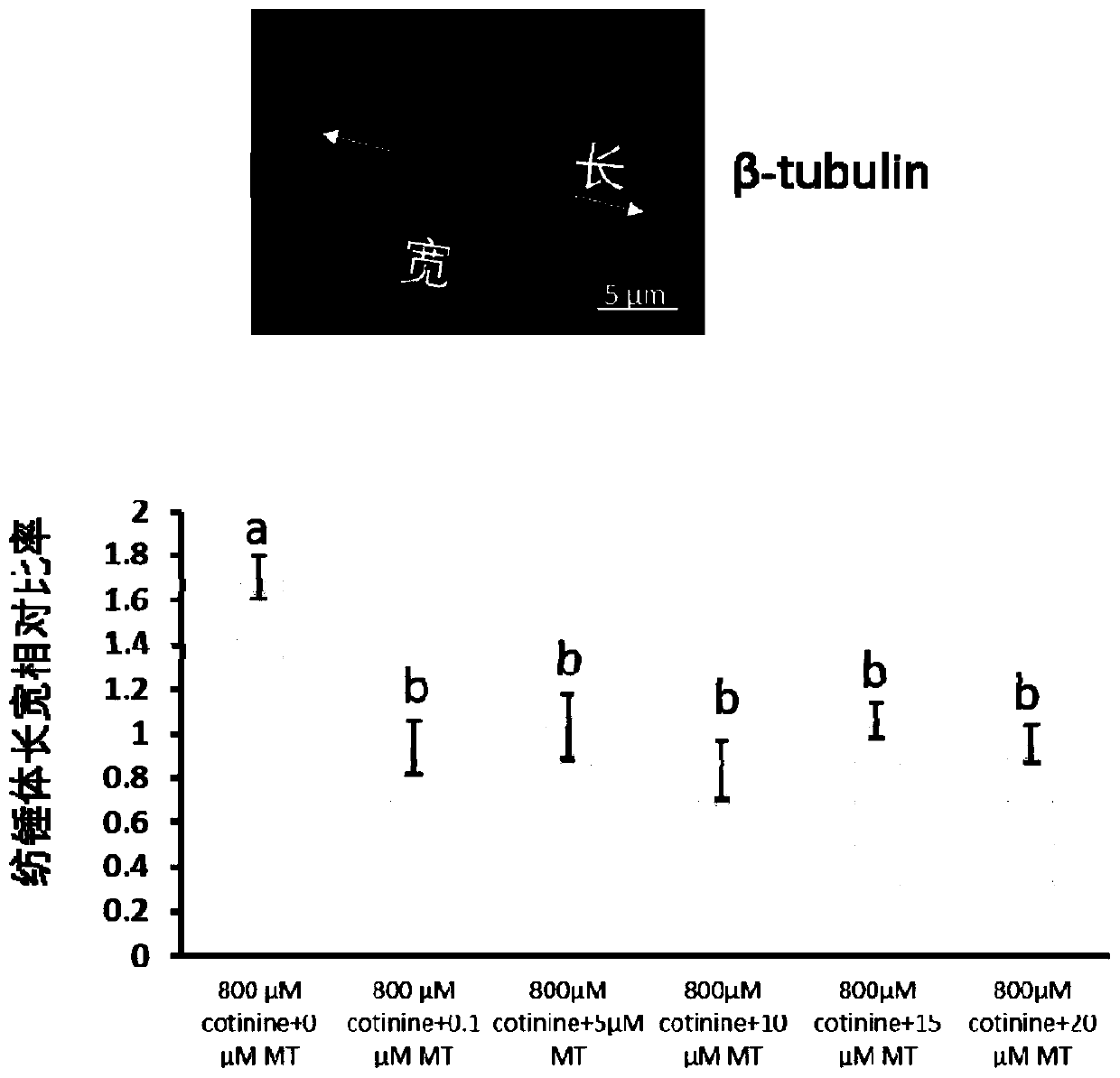

Application of melatonin in preparation of medicine for improving oocyte quality

InactiveCN110833542AAffect qualityImprove reproductive abilityOrganic active ingredientsSexual disorderCotininePhysiology

The invention discloses an application of melatonin in preparation of a medicine for improving oocyte quality. According to the invention, melatonin is directly added into an oocyte in-vitro maturation culture solution, which proves that the melatonin can relieve the reduction of the quality of the cotinine-induced oocytes and is shown as reduction of the ROS level in the oocytes, reduction of aneuploidy formation, promotion of uniform distribution of actin, improvement of the form of spindles and improvement of mitochondrial functions, and then the later fertilization rate of the oocytes is remarkably increased. The invention provides a method for improving the influence of the main metabolite cotinine of nicotine in the blood of a smoker on the quality of female oocytes, and provides aneffective method for improving the reproductive capacity of smoking women.

Owner:NANTONG UNIVERSITY

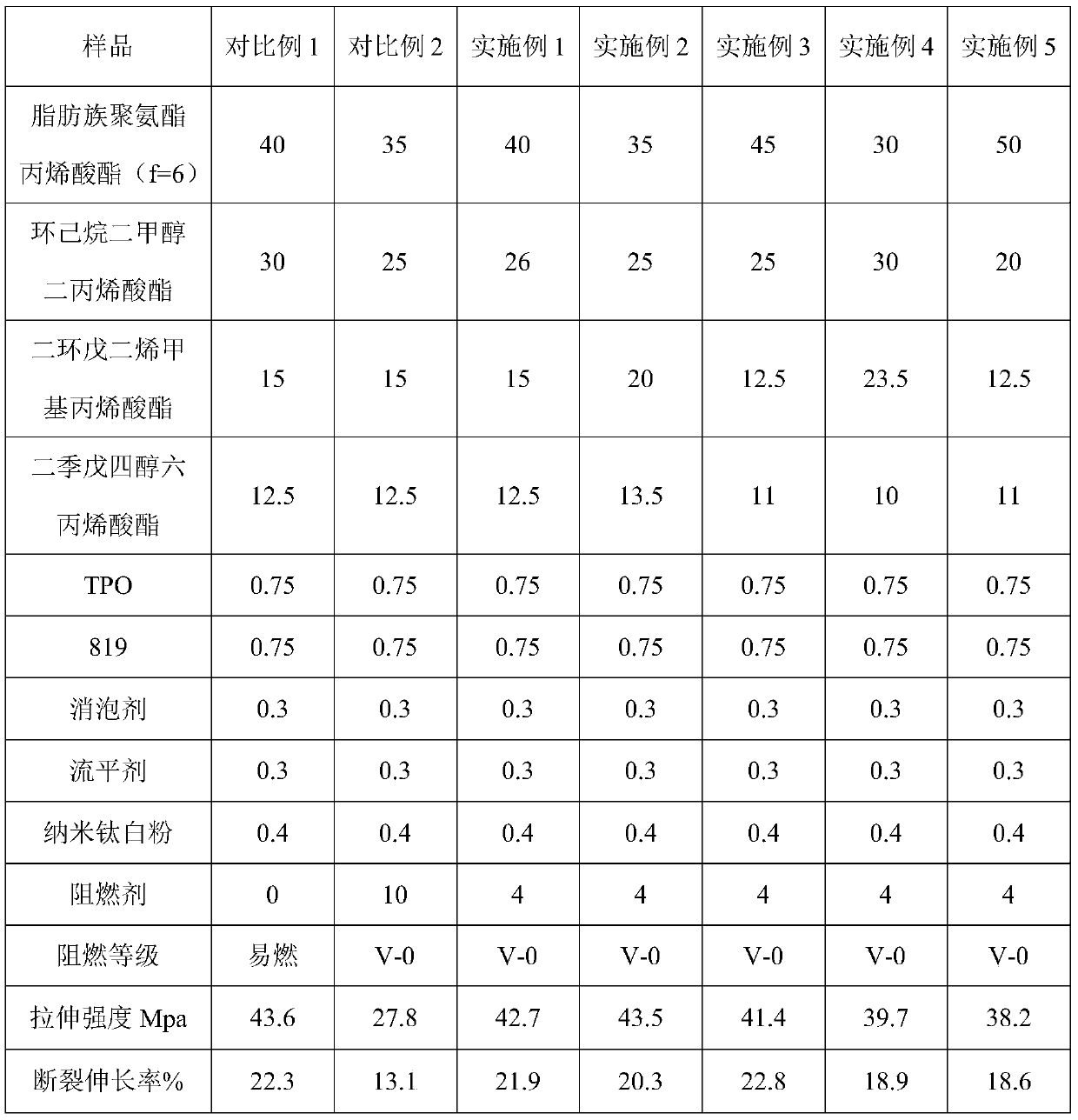

Efficient DLP photosensitive resin with flame retardant property

The invention belongs to the technical field of photocuring materials, and particularly relates to efficient DLP photosensitive resin with flame retardant property, which is composed of the followingcomponents in parts by mass: 25-50 parts of acrylate resin, 40-60 parts of a reactive diluent, 0.5-2 parts of an initiator, 1-10 parts of a flame retardant, 0.2-1 part of other assistants and 0.1-1 part of a filler. The DLP photosensitive resin material provided by the invention can be subjected to a polymerization reaction to complete curing when the wavelength is 380-410 nm, and has a good flameretardant effect, the adopted flame retardant is halogen-free and low in environmental pollution, the reactive diluent and an oligomer with high functionality are adopted, the printing efficiency ishigh, the time cost is greatly reduced, and the DLP photosensitive resin material can be widely applied to the fields with flame-retardant requirements on materials.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

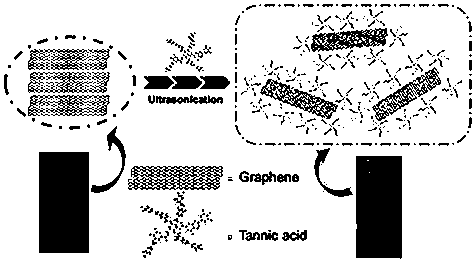

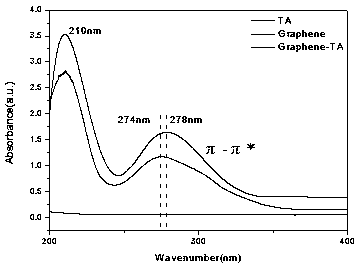

Preparation method and application of GO-TA/waterborne epoxy composite coating

InactiveCN108587401AImprove corrosion resistanceBest dosageAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphite

The invention discloses a preparation method and the application of GO-TA / waterborne epoxy composite coating. The preparation method comprises the following steps: (1), preparing a base material; (2),preparing a GO-TA dispersion; (3), preparing the GO-TA / waterborne epoxy composite coating. Test and analysis show that tannic acid and graphene are combined through a pi-pi conjugate interaction force of a benzene ring, and the graphene can be uniformly and stably dispersed in an aqueous solution while the complete structure of the grapheme is not destroyed. Through mixing of the modified graphene and waterborne epoxy resin, the corrosion resistance of waterborne epoxy coating can be greatly improved, and the application field of the graphene is widened.

Owner:SOUTHWEST PETROLEUM UNIV

Co-fermented Sichuan pepper beer and preparation method thereof

The invention discloses a co-fermented Sichuan pepper beer. 0.1-0.6 part of humulus lupulus is added into 100-200 parts of saccharified wort in batches to prepare wort, then, precipitation separationis conducted, 5-10 parts of Sichuan pepper nano-powder is added, after first-time sterilization, 0.1-0.3 part of commercially available beer yeast is added to carry out twice fermentation, and then sterilization is conducted again to obtain the co-fermented Sichuan pepper beer. The co-fermented Sichuan pepper beer is prepared by co-fermenting Sichuan pepper and beer, the wort is used for producingalcohol under the action of microorganisms, increasing of alcohol concentration facilitates changing and dissolving out of internal substances of the Sichuan pepper, and the solubility of some flavorsubstances and active substances in the Sichuan pepper can be gradually improved along with increasing of the alcohol concentration, so that the relative content of the characteristic flavor substances in the Sichuan pepper is improved, and a flavor stereoscopic feeling of the Sichuan pepper is enhanced. Through reasonable design and blending, the flavor of the Sichuan pepper and the flavor of the beer are fused and harmonized, and thus the co-fermented Sichuan pepper beer gives people comfortable and cheerful feelings.

Owner:汉源县昊业科技有限公司

Special niobium and vanadium containing chilled cast iron roll for splitting rack and production technology

PendingCN108315632AImprove purityChemically activeFurnace typesRollsRare-earth elementChemical composition

The invention relates to a chilled cast iron roll manufacturing method, in particular to a manufacturing method for a special niobium and vanadium containing chilled cast iron roll for a splitting rack. An outer layer and a core part of the roll are prepared through double chemical components. The outer layer components comprise 2.9%-3.2% of C, 0.25%-0.60% of Si, 0.2%-0.5% of Mn, smaller than or equal to 0.05% of P, smaller than or equal to 0.03% of S, 0.5%-0.8% of Cr, 3.5%-4.0% of Ni, 0.3%-0.6% of Mo, 0.1%-0.3% of V, 0.1%-0.3% of Nb and the balance Fe. The core part components comprise 3.2%-3.5% of C, 2.2%-2.4% of Si, 0.3%-0.5% of Mn, smaller than or equal to 0.05% of P, smaller than or equal to 0.03% of S, 0.15% of Cr, smaller than or equal to 0.04 of Mg and the balance Fe. When molten iron is smelted, 1-3 kg of yttrium-based heavy rare earth modificator is added for each ton; the chemical property of rare earth elements is active, and stable compounds can be formed by the rare earthelements and S, O, H and N in molten steel; the affinity of the yttrium and S is high, after the rare earth modificator is added, the S content in the steel can be further reduced, and hot shortnessof the roll is prevented; and the yttrium-based heavy rare earth modificator can also refine grains and improve the tensile strength and impact toughness.

Owner:湖州中杭轧辊有限公司

Silicon-aluminum alloy material and preparation method thereof

The invention relates to a silicon-aluminum alloy material. The silicon-aluminum alloy material is characterized by comprising the components of, in percentage by weight, 10.0%-12.0% of Si, 1.5%-2.5% of Cu, 0.3% of Mg or less, 0.55% of Mn or less, 0.25% of Sn or less, 0.45% of Ni or less, 1.00% of Zn or less, 0.8% of Fe or less, 0.1% of Pb or less, 0.1% of Hg or less, 100 ppm of Cd or less, 0.02%-0.19% of rare earth(RE) elements, 0.15%-0.20% of Zr and the balance Al. The silicon-aluminum alloy material has the good conductivity and higher strength and elongation, and is high in oxidation resistance. The RE elements and zirconium elements are added in aluminum alloy, harmful elements and gas are removed, molten aluminum is purified, and the strength, plasticity and resistance to pressure of the silicon-aluminum alloy material are improved.

Owner:张小龙

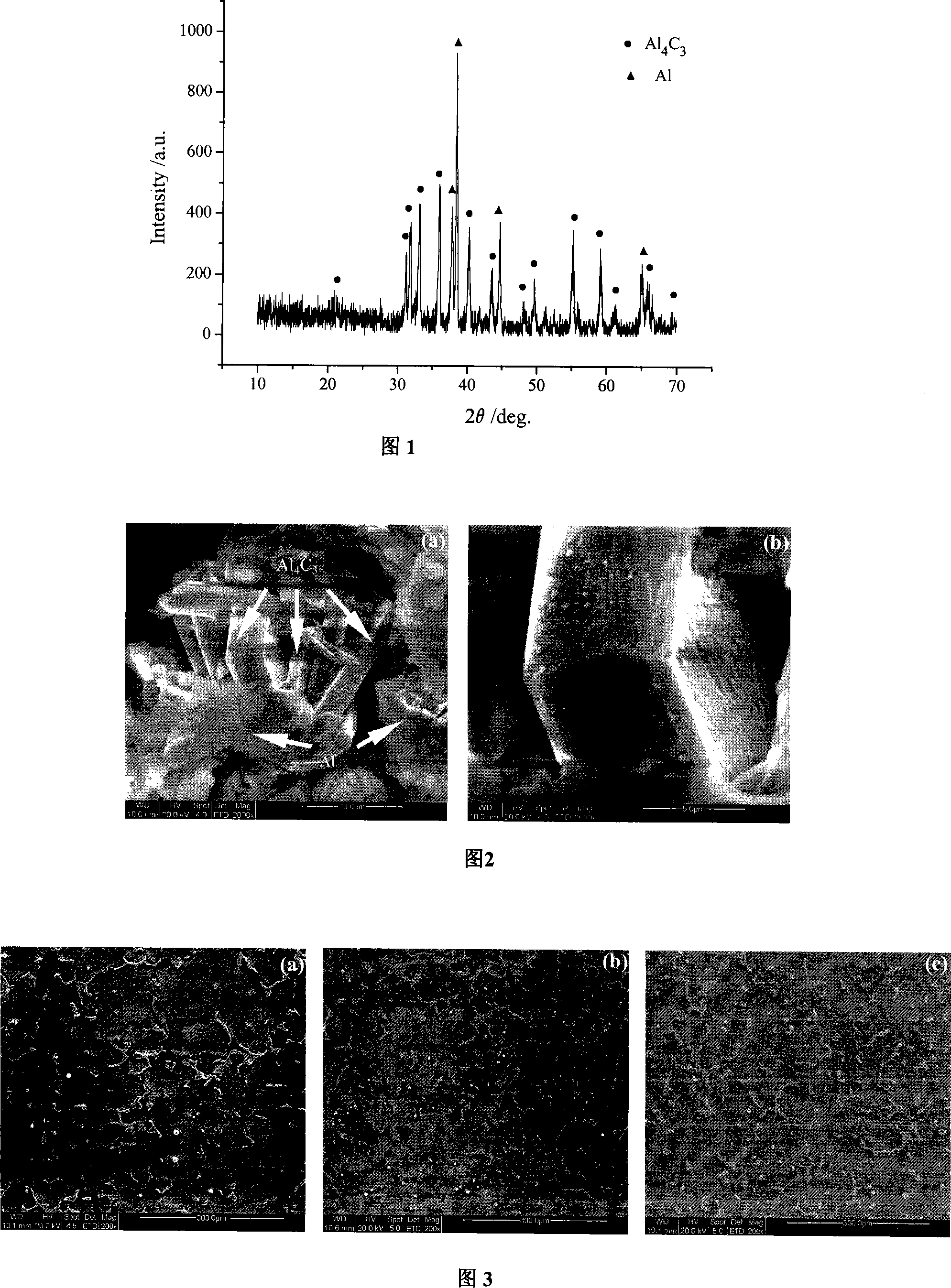

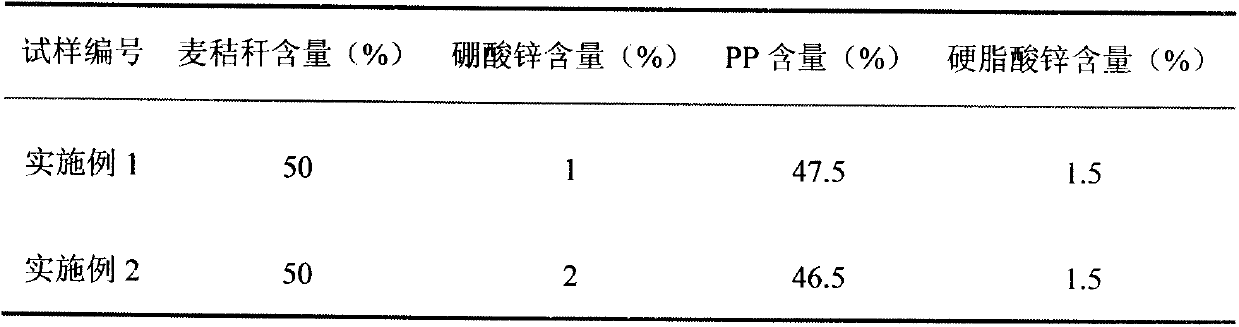

Mg-Al series alloy composite grain refiner and method for making same

The present invention provides one kind of composite grain refiner for Mg-Al alloy and its preparation process. The composite grain refiner has the chemical composition including C 5-15 wt%, calcium 2.8-28 wt% or Ce 3-6 wt%, and Al for the rest. Its preparation process includes the following steps: mixing aluminum powder and carbon powder; pressing into block and stoving, setting inside corundum crucible and covering with refractory powder, isothermal treatment inside a box-type resistance furnace at 1000-1200 deg.c for 30-120 min to prepare intermediate Al-Al4C3 alloy, and remelting together with aluminum ingot and intermediate Al-70 %Ca or Al-10 %Sr alloy to prepare Al-Al4C3-Ca / Sr as composite grain refiner finally. The composite grain refiner can fine grains of Mg-Al alloy obviously.

Owner:WUHAN UNIV OF TECH

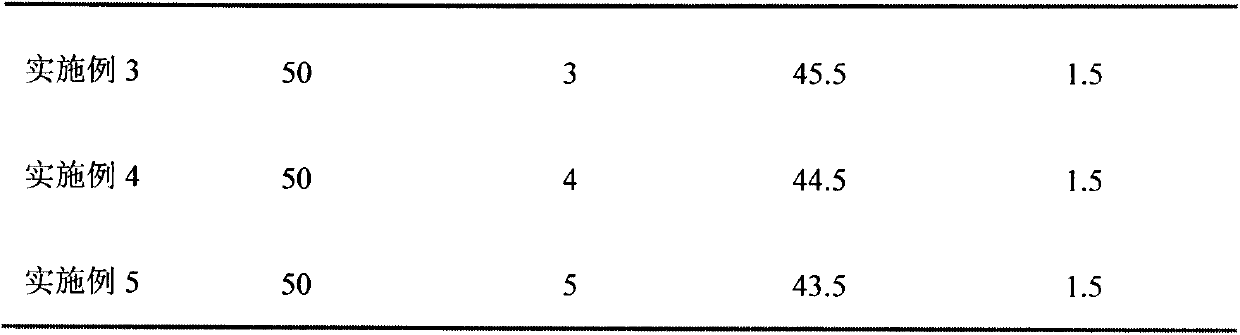

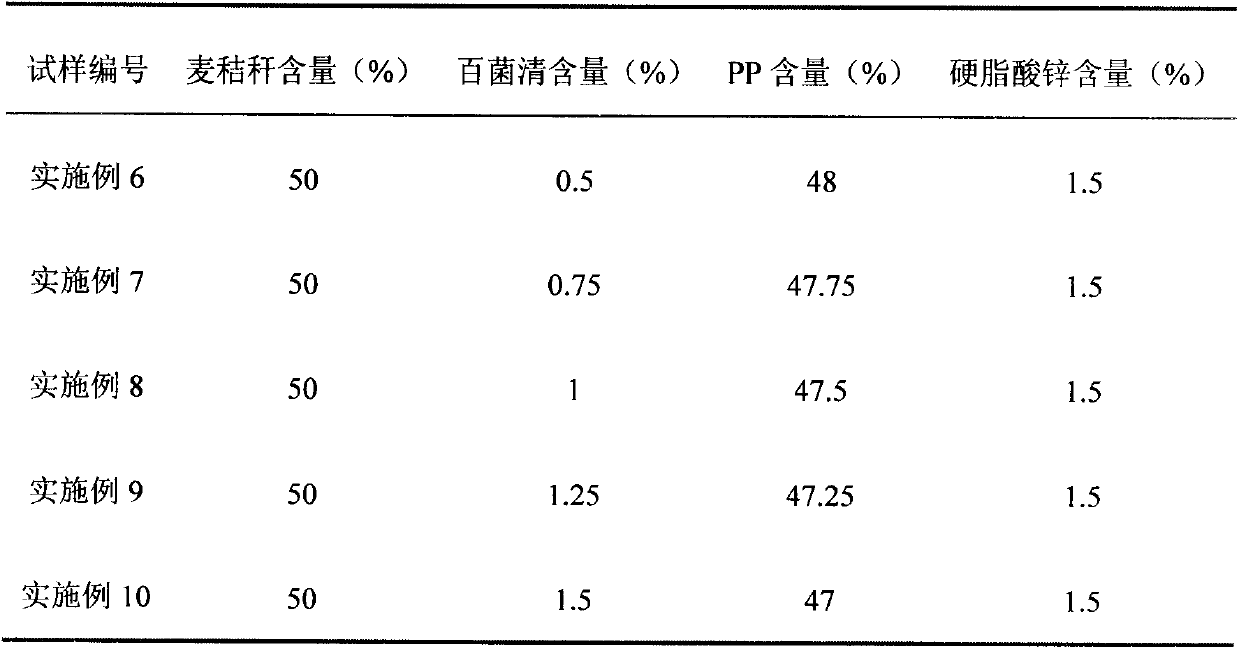

Formula for enhancing mold corrosion resistance of wheat straw/PP (polypropylene) wood-plastic composite material by using antimicrobial agent

InactiveCN104046048AExtended service lifeBest dosageWeather/light/corrosion resistanceZinc borateFilling materials

The invention relates to a formula for enhancing mold corrosion resistance of a wheat straw / PP (polypropylene) wood-plastic composite material by using antimicrobial agents. A filling material wheat straw modified by a coupling agent KH550 and a matrix PP are subjected to compounding and hot pressing to prepare the wheat straw / PP wood-plastic composite material with or without three antimicrobial agents (zinc borate, chlorothalonil and SD-36M); and five mold corrosion experiments are performed on the wheat straw / PP wood-plastic composite material with or without the antimicrobial agents to analyze the improvement action of the antimicrobial agents on the corrosion resistance of the wheat straw / PP composite material and obtain the optimal addition amounts of the antimicrobial agents. The result indicates that the zinc borate and chlorothalonil have favorable improvement action on the corrosion resistance of the wheat straw / PP composite material, and the improvement action of the SD-36M is small; the optimal addition amounts of the zinc borate and chlorothalonil are respectively 1% and 1.25%; and the wheat straw / PP composite material has favorable comprehensive properties after mold corrosion.

Owner:NANJING AGRICULTURAL UNIVERSITY

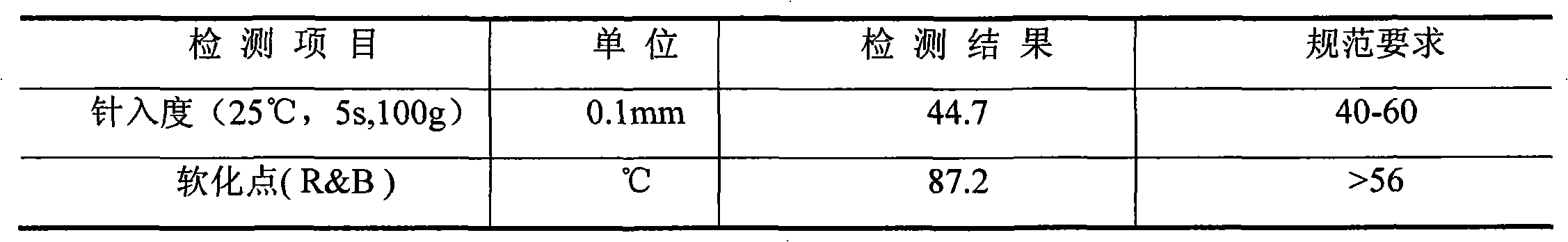

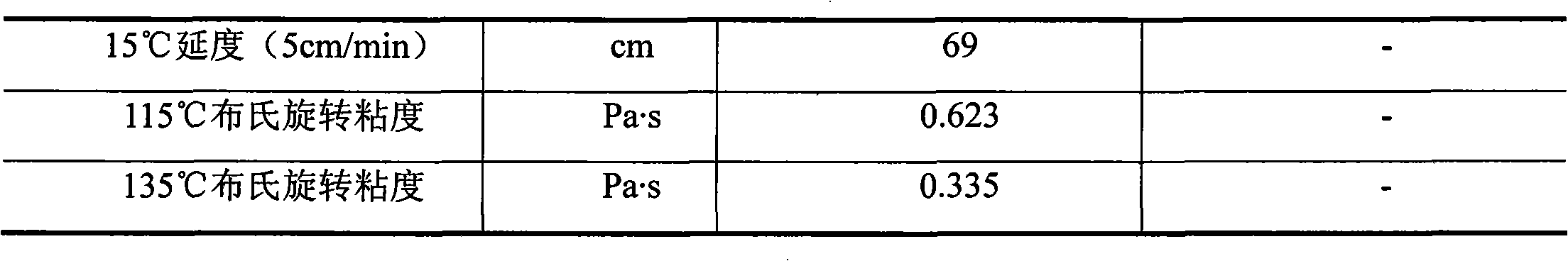

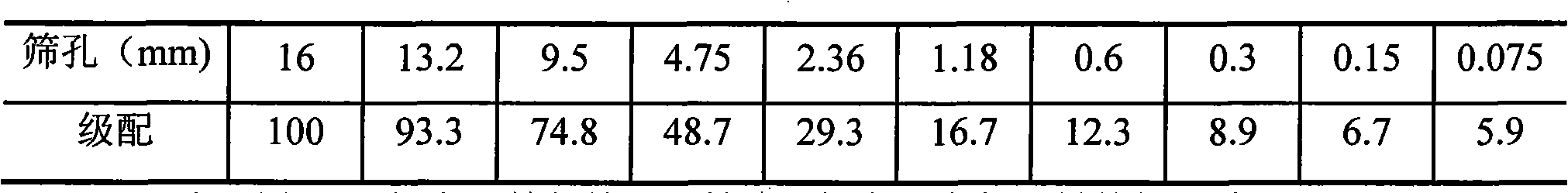

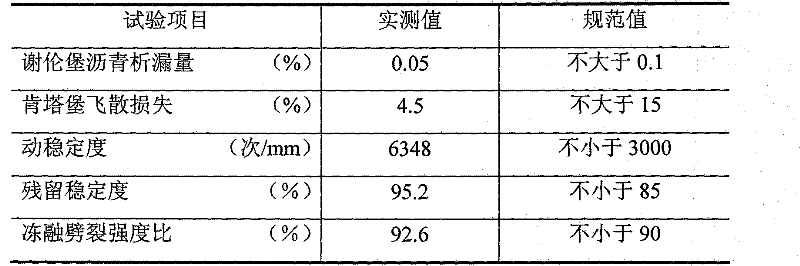

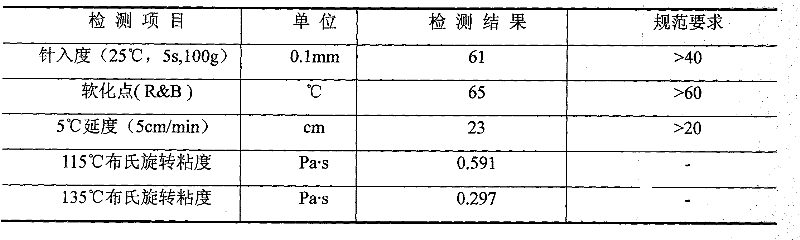

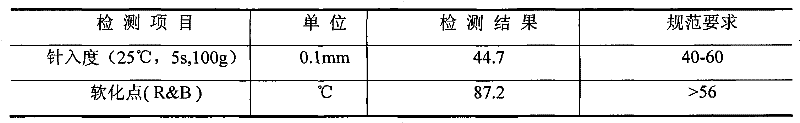

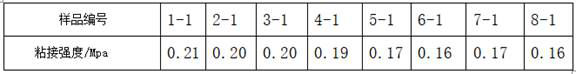

Preparation method of low-carbon asphalt mixture

ActiveCN101837603AReasonable dosageOptimum Oil QuantityCeramic shaping apparatusPavement engineeringMaterials science

The invention belongs to the technical field of highways and urban roads, and in particular relates to a preparation method of a low-carbon asphalt mixture. The preparation method comprises the concrete step of directly adding a low-carbon agent into modified asphalt or substrate asphalt, which reduces the emission of carbon dioxide, the mixing temperature and the paving temperature of the asphalt mixture and the consumption of energy sources. The mixing temperature is generally 110-140DEG C and the compaction temperature is generally 80-100DEG C; and compared with the hot mixing asphalt mixture, the emission of the carbon dioxide is reduced by over 45 percent and the consumption of the energy sources can be reduced by 12-18 percent. The preparation method can play roles of reducing the emission of the carbon dioxide and saving the energy sources, is a preparation method of the asphalt mixture with greenness, environmental protection and energy saving and can be applied to paving the urban roads, various grades of highways and other pavement engineering.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

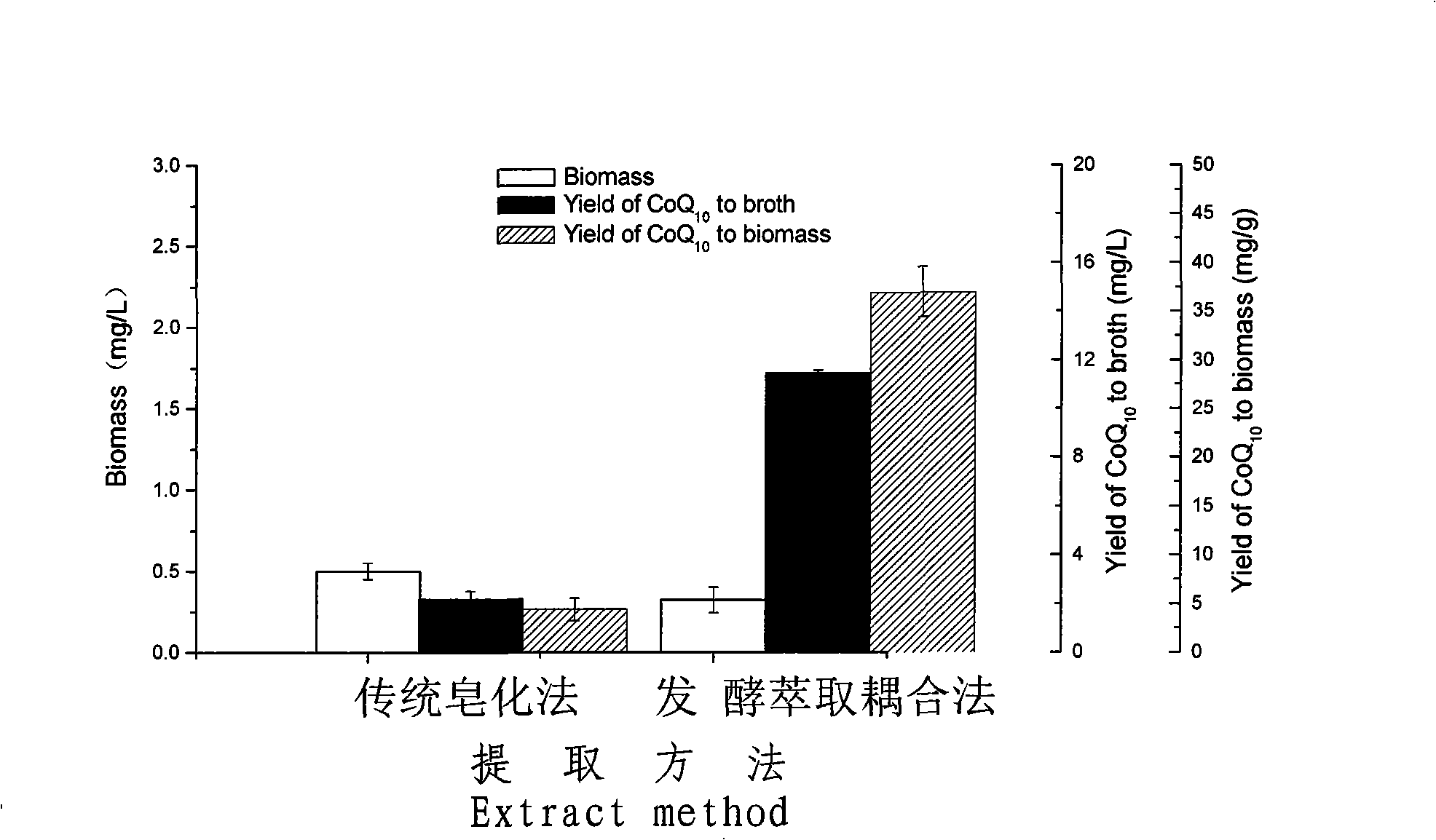

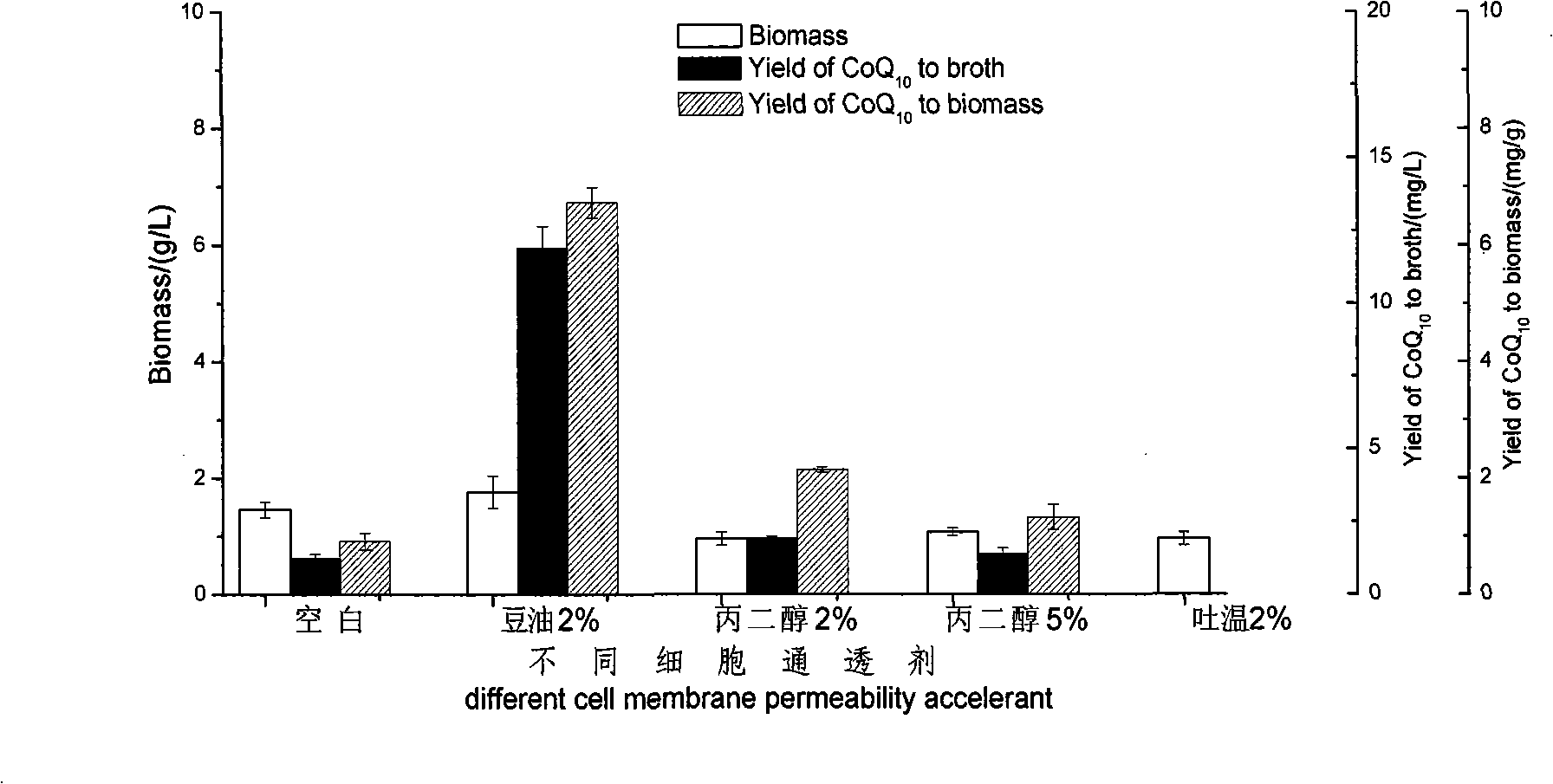

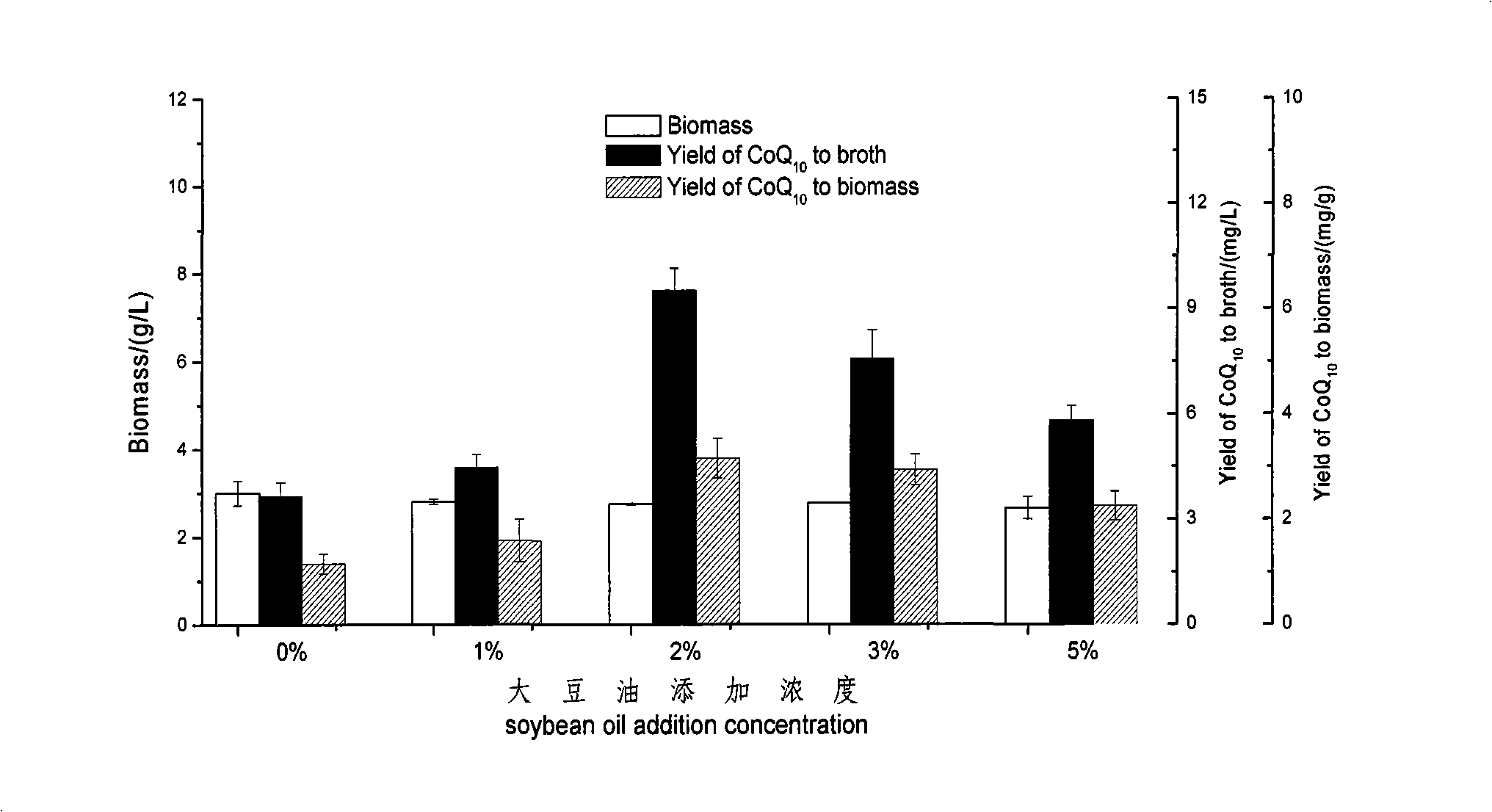

Process for preparing coenzyme Q10 by sphingosine unit cell strain fermentation, extraction and coupling

ActiveCN101307337AImprove extraction efficiencyHigh recovery rateMicroorganism based processesFermentationLiquid mediumOrganic layer

The invention provides a method for making coenzyme Q10 by means of sphingosine monad fermentation, extraction and coupling. The method comprises the following steps that: sphingosine monad strain is inoculated in liquid medium suitable for sphingosine strain; soybean oil with the volume occupying 1 to 5 percent of that of the liquid medium is added in the liquid medium so as to carry out cultivation at a temperature of between 25 and 28 DEG C for 24 to 36 hours; then, normal hexane with the volume occupying 20 to 50 percent of that of the liquid medium is added in the liquid medium so as to carry out cultivation at a temperature of between 25 and 28 DEG C for 6 to 12 hours; after the reaction is completed, the reaction liquid undergoes delamination and then the organic layer is taken out so as to obtain the coenzyme Q10 after separation and purification. The method has the advantages of high recovery rate of extraction solvent, economization on manpower and material resources, simple and time-saving method and high yield of coenzyme Q10, and is propitious to industrialized production.

Owner:ZHEJIANG UNIV OF TECH

Novel technique for processing apple-pear juice and product

The present invention relates to fruit juice beverage, and is especially one kind of new apple pear juice and its producing process. The new apple pear juice is produced with new apple pear, pectase accounting for 0.01-0.012 % of juice weight, and amylase accounting for 0.003-0.004 % of juice weight. The new apple pear juice is yellowish, sour and sweet, and rich in fruity fragrance. It has the health functions of moistening lung, eliminating phlegm, relieving cough, promoting the secretion of saliva to quench thirst, etc.

Owner:辽宁省果树科学研究所

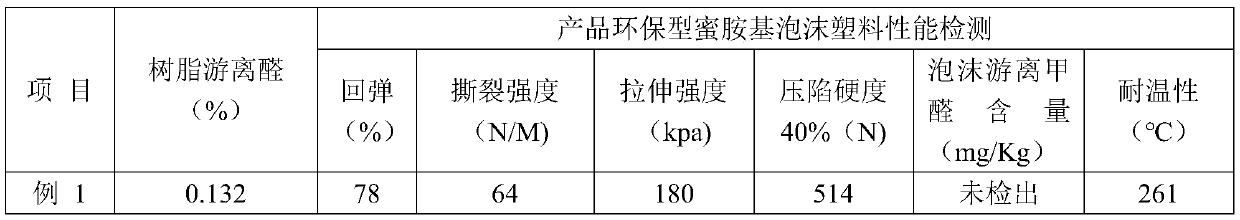

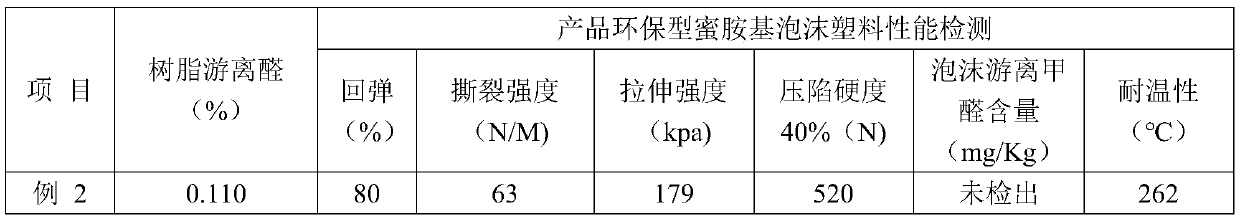

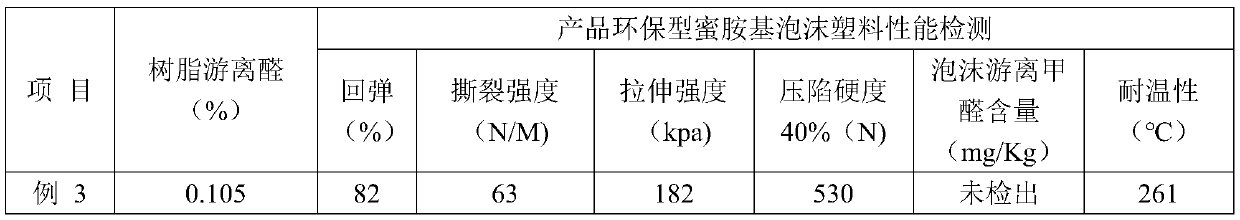

Preparation method of environment-friendly type melamine-based foamed plastic

The invention discloses a preparation method of environment-friendly type melamine-based foamed plastic, comprising the following steps: firstly adding melamine, paraformaldehyde and water into a reactor, adding a modified monomer, adjusting pH value of the solution, and then reacting by steam heating; adding a formaldehyde-removal functional monomer after the reaction and continuously stirring and reacting to obtain expandable low-formaldehyde melamine-based resin; successively adding an emulsifier, a compound curing agent and a foaming agent into an auxiliary agent reaction vessel and uniformly mixing to obtain a mixed auxiliary agent; cooling the resin, respectively metering and carrying out high-speed emulsification on the resin and the mixed auxiliary agent in a twin-screw extruder, carrying out microwave foaming after the emulsification to obtain melamine-based foam M1; and finally drying the melamine-based foam M1 successively by superheated steam and microwave drying treatmentso as to obtain the environmentally-friendly type melamine-based foamed plastic product. According to the invention, industrial production of the melamine-based foamed plastic product with zero formaldehyde release is realized, and the key indexes for industrialization of the melamine-based foamed plastic and the environmental safe process bottleneck are solved.

Owner:PUYANG GREEN FOAM CO LTD

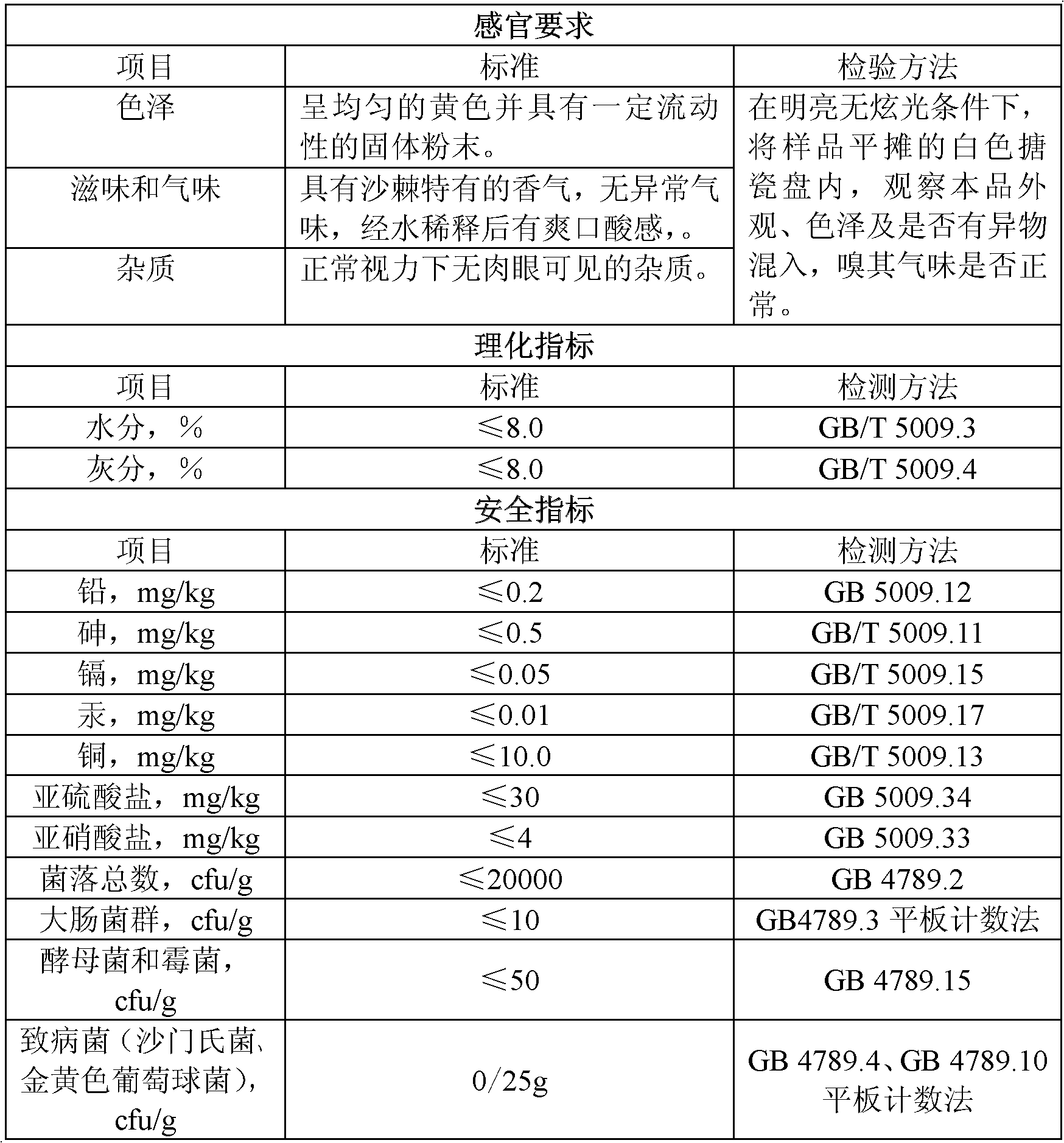

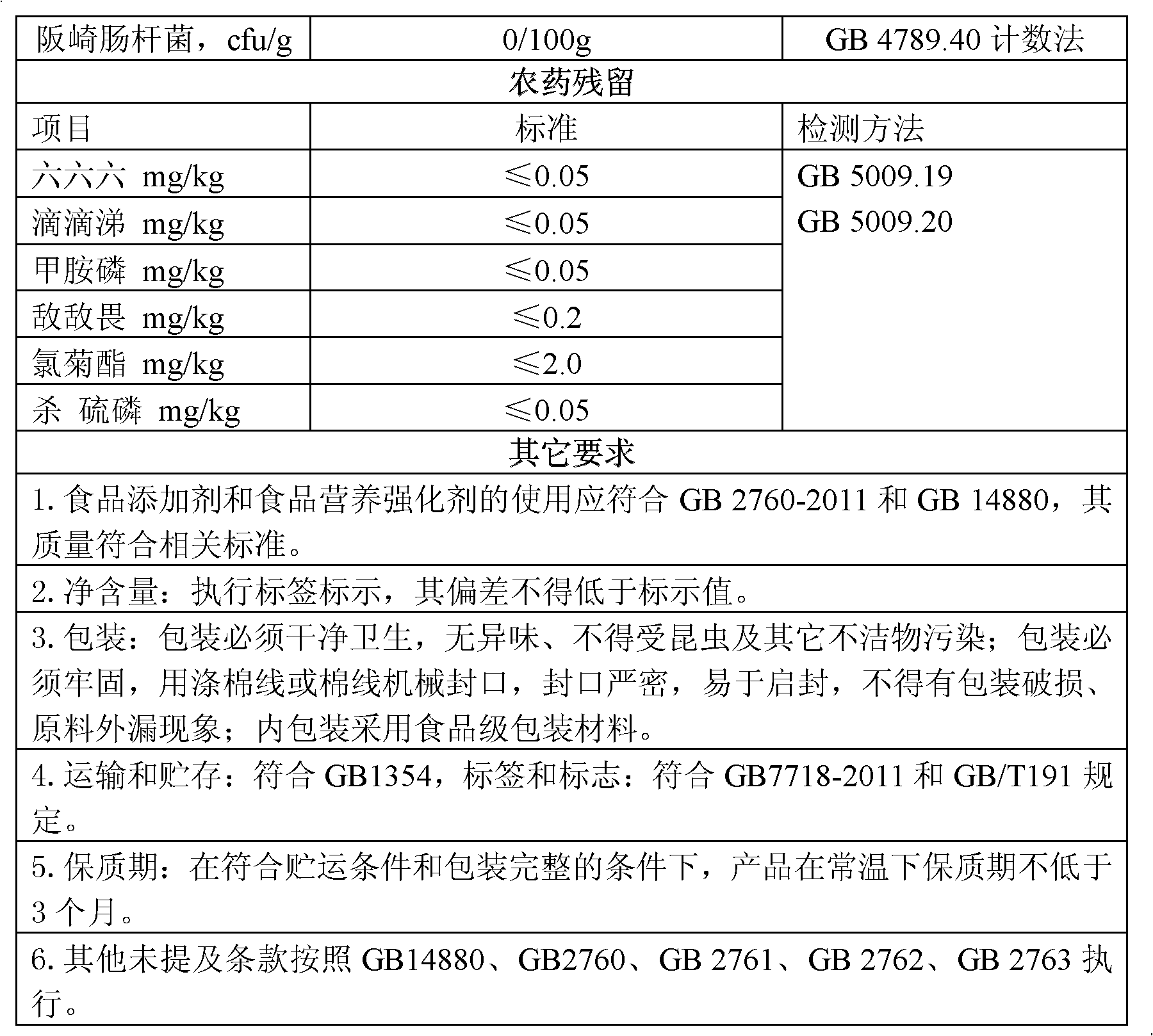

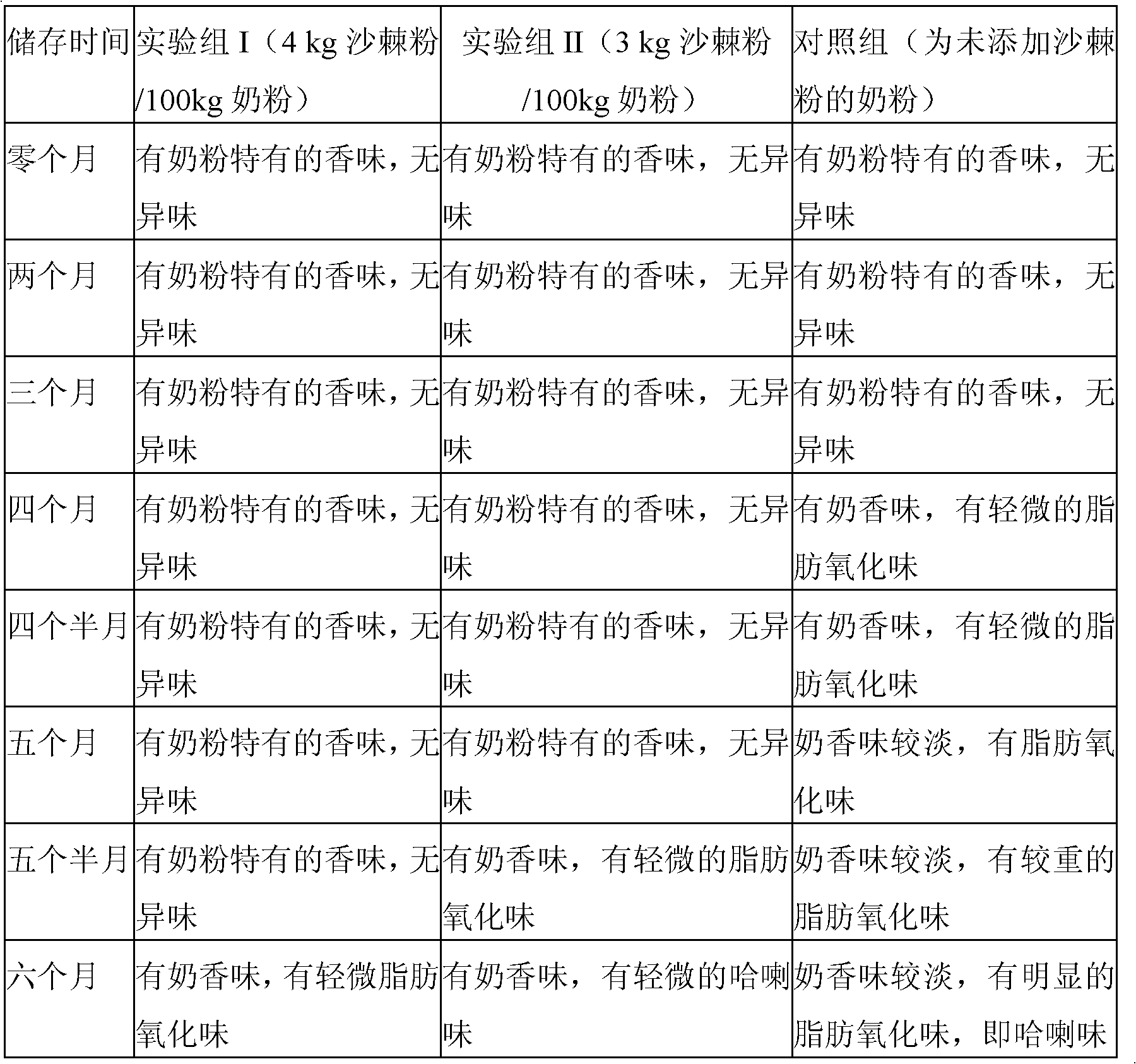

Sea-buckthorn nutrient milk powder and preparation method thereof

The invention relates to the field of dairy processing and in particular to a sea-buckthorn nutrient milk powder and preparation method thereof. Based on 100 sea-buckthorn nutrient milk powder parts by weight, the raw materials include fresh milk 90-100 parts by weight, sea-buckthorn powder 4.0-6.5 parts by weight, granulesten 0.1-0.25 part by weight, bifidobacterium 0.004-0.01 parts by weight, fructooligosaccharides 0.4-0.5 part by weight and galactooligosacchrides 1.0-11 parts by weight. The sea-buckthorn powder parts are super-micro grinded instant sea-buckthorn powder, and preferably 5.0-6.0 parts by weight. The sea-buckthorn nutrient milk powder has the functions of anti-oxidation, anti-aging and organic body immunity enhancement and simultaneously improves sensing quality of the milk powder. Besides, the invention further provides the optimum adding quantity of the sea-buckthorn powder, thereby resolving the problem that the sea-buckthorn milk powder are adhered to walls during production process.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Three-dimensional patterned slip-proof gloves and preparation process thereof

InactiveCN108299688ABest dosageImprove gripDomestic articlesCoatingsLatex gloveCarboxymethyl cellulose

The invention discloses three-dimensional patterned slip-proof gloves, and belongs to the technical field of latex gloves. The three-dimensional patterned slip-proof gloves comprise the following components in parts by weight: 28 parts of pre-vulcanized natural latex, 5 parts of sodium carboxymethyl cellulose, 6 parts of colloidal calcium carbonate and 1 part of an emulsifier, and further comprisepotassium hydroxide, wherein the dosage of potassium hydroxide is 100-375 g based on a total amount of 200 kg of the raw materials. The invention further provides a preparation process of the three-dimensional patterned slip-proof gloves. According to the invention, the dosage of potassium hydroxide in the latex is controlled to realize coating pattern and three-dimensional effect on surfaces ofthe gloves; and a contrast experiment is performed on the pre-vulcanized latex without potassium hydroxide, and a wrinkling mechanism of patterns is discussed to obtain an optimal dosage of potassiumhydroxide, so that the surfaces of the gloves have balanced coating patterns and strong three-dimensional effect.

Owner:SHANDONG DENGSHENG SAFETY PROD

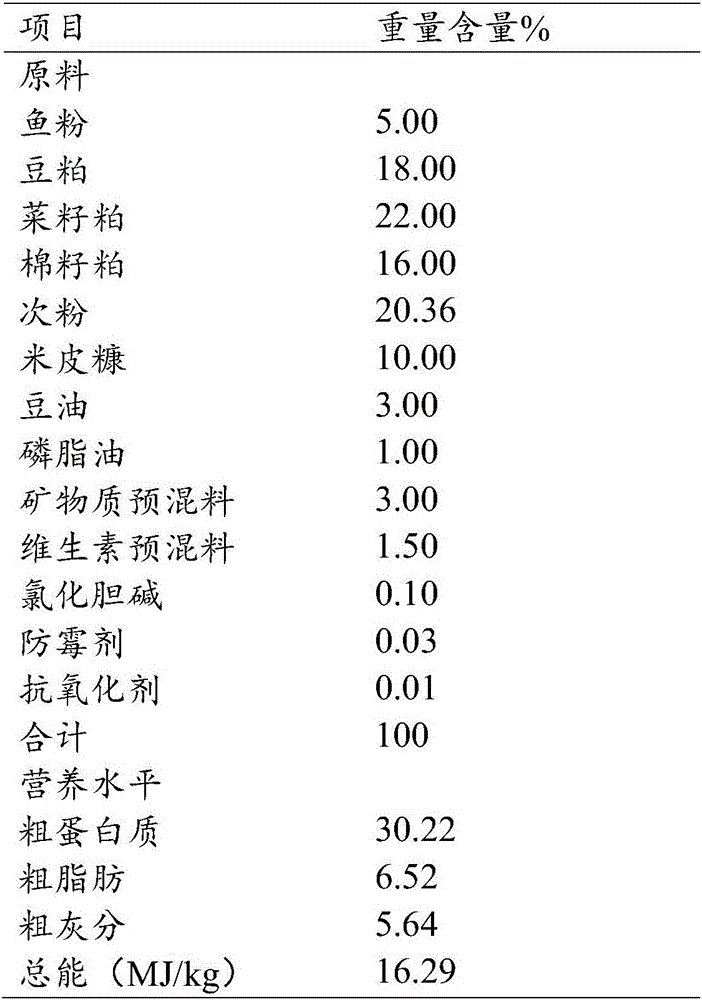

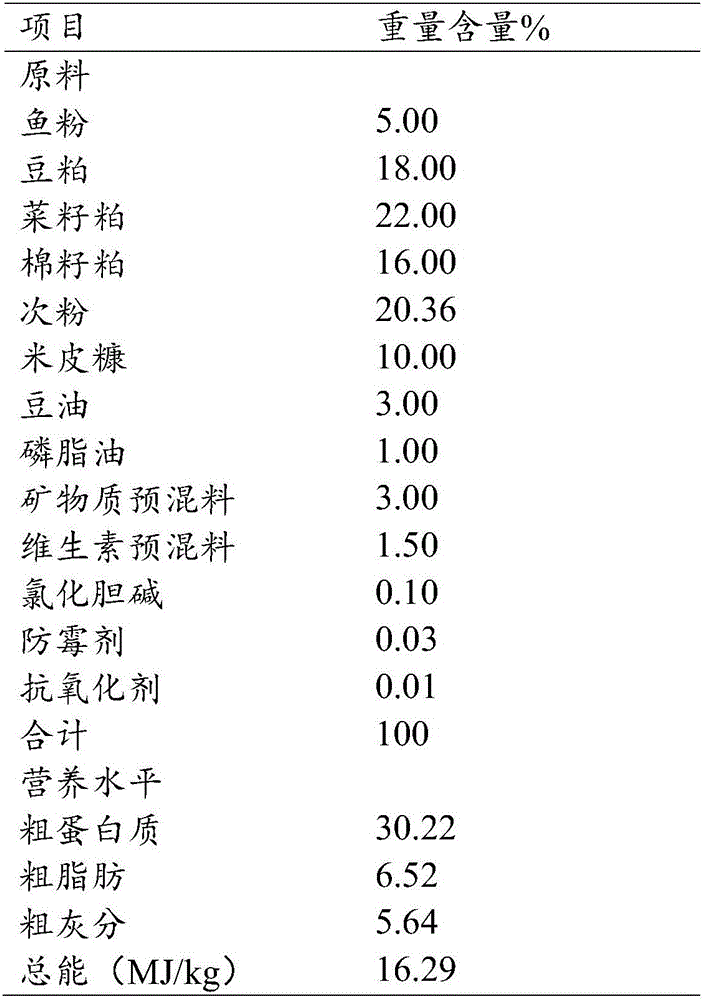

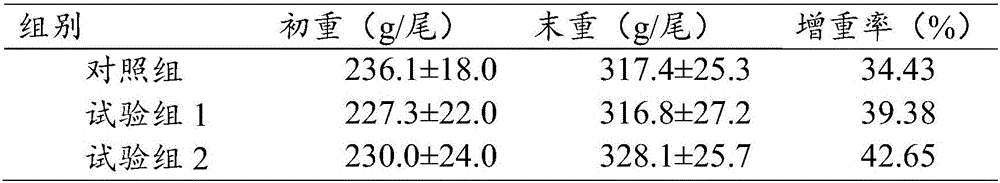

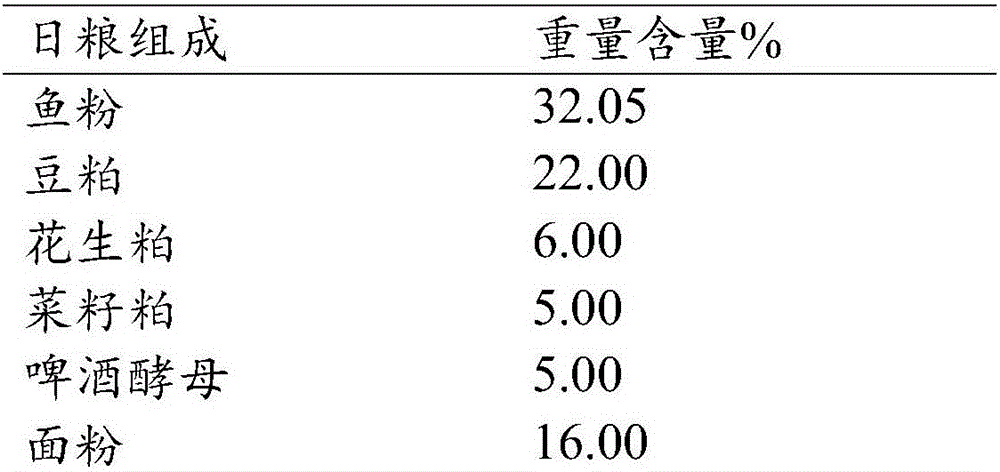

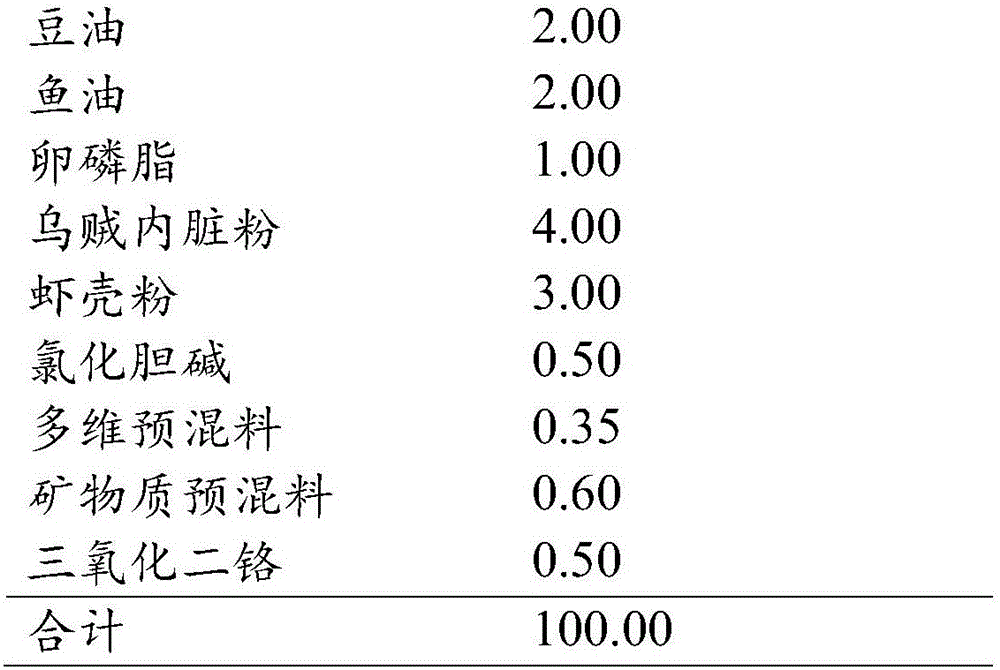

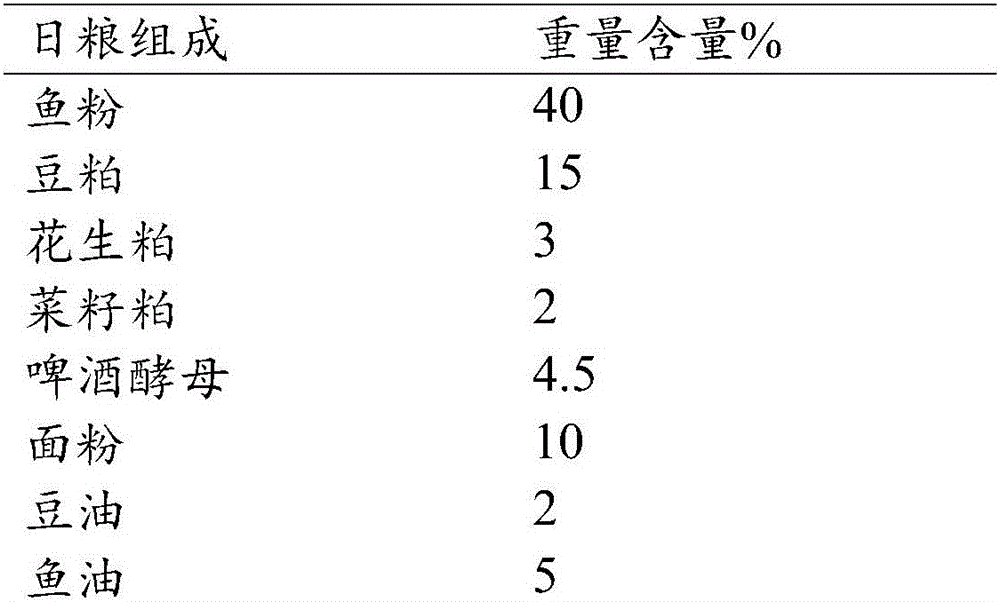

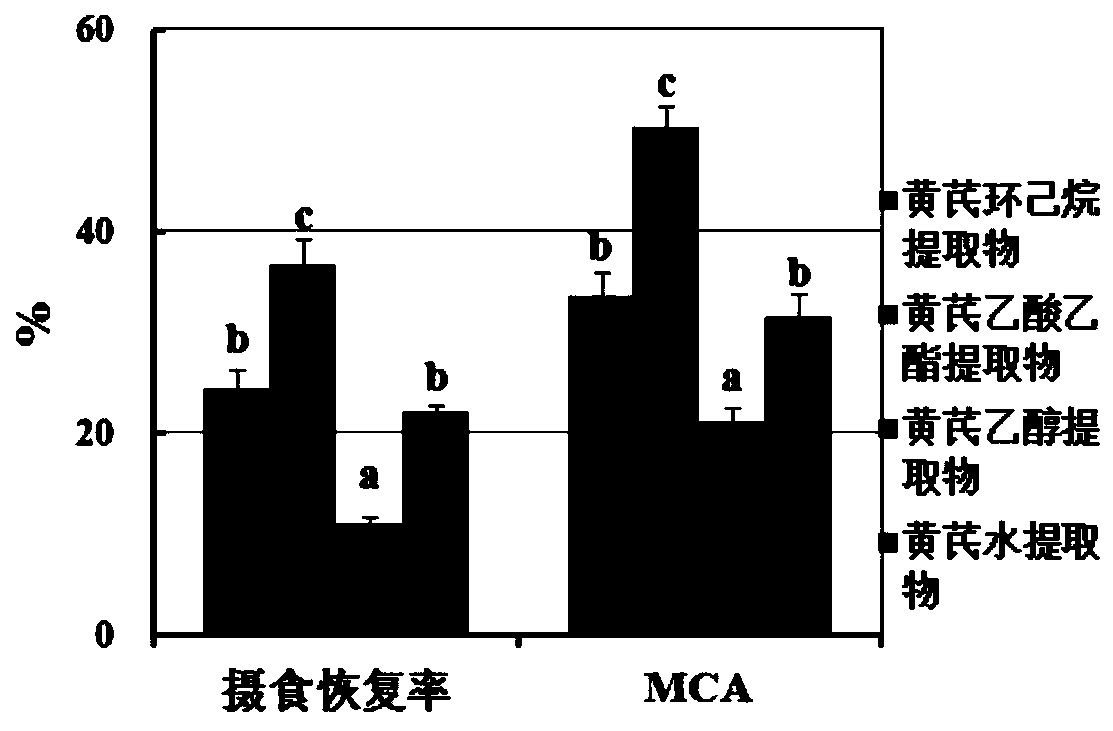

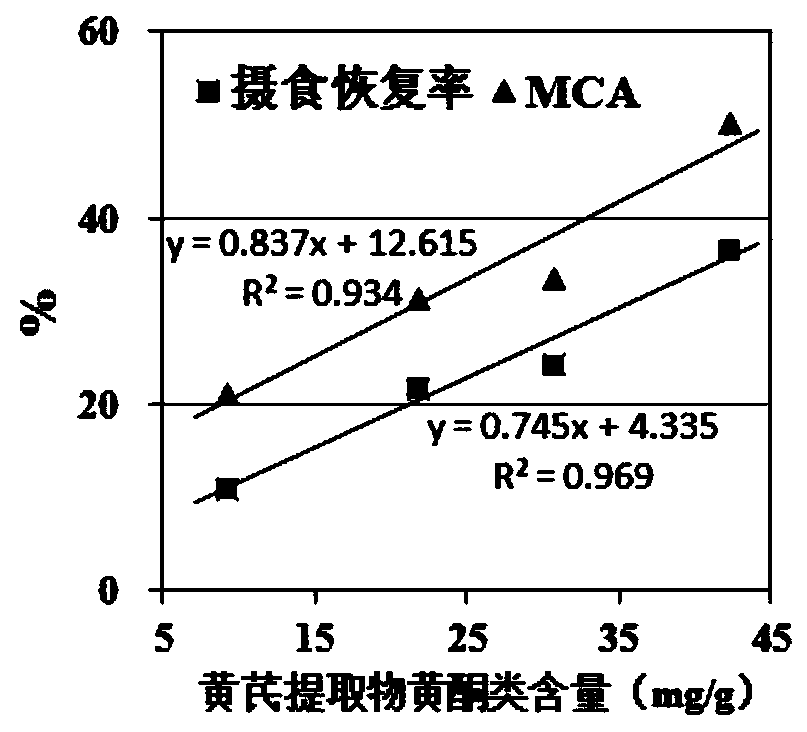

Application of astragalus membranaceus extractive for preparing freshwater fish anti-stress agent and preparation method thereof

PendingCN110063428ASuppress stress responsePrevent rolloverFood processingClimate change adaptationAnti stressFresh water organism

The invention provides application of an astragalus membranaceus extractive for restraining freshwater fish culture stress, a feed and a preparation method thereof. The preparation method of the astragalus membranaceus extractive comprises the steps of drying and smashing rhizomes of astragalus membranaceus, sequentially adopting cyclohexane and ethyl acetate for extracting astragalus membranaceuspowder, and after filtering, performing reduced pressure distillation on an ethyl acetate filtrate to reach the constant weight to obtain the astragalus membranaceus extractive. The invention furtherprovides the ratio of the astragalus membranaceus extractive in the anti-stress feed and a preparation method of the feed. The astragalus membranaceus extractive is adopted as the freshwater anti-stress agent to be applied into the feed, can restrain the stress reaction caused by high-density copper sulfate and dipterex in freshwater fish culture, improves the freshwater fish anti-stress ability,and lowers the morbidity and death rate, meanwhile, the novel application of astragalus membranaceus is developed, and astragalus membranaceus resource are effectively utilized.

Owner:NEIJIANG NORMAL UNIV

Special aluminum alloy material for steel-aluminum composite radiator and preparation method thereof

The invention relates to a special aluminum alloy material for a steel-aluminum composite radiator. The special aluminum alloy material is characterized by comprising, by mass, 12.2 to 13.3% of Si, 2.6 to 2.8% of Cu, 0.4 to 0.5% of Mg, 0.1 to 0.25% of Mn, 0.01 to 0.023% of Sn, 0.03 to 0.05% of Ni, 0.07 to 0.1% of Ti, 0.7 to 1.1% of Zn, 0.8 to 0.95% of Fe, 0.03 to 0.04% of Pb, 0.0025 to 0.003% of Hg, 0.001 to 0.0015% of Cd, 0.015 to 0.023% of rare earth elements (RE) and 0.1 to 0.15% of Zr, with the balance being Al. According to a technical scheme in the invention, the contents of silicon, magnesium, iron and copper in the aluminum alloy are optimized, so aluminum alloy for a deep-cavity thin-wall die casting of the radiator is easy to mold, reduced in the phenomenon of mold sticking and improved in corrosion resistance; and the rare earth elements and elemental zirconium are added into the aluminum alloy, so harmful elements and gases are removed, molten aluminum is purified, and the strength, plasticity and pressure resistance of the aluminum alloy are improved.

Owner:ZHEJIANG RONGRONG IND

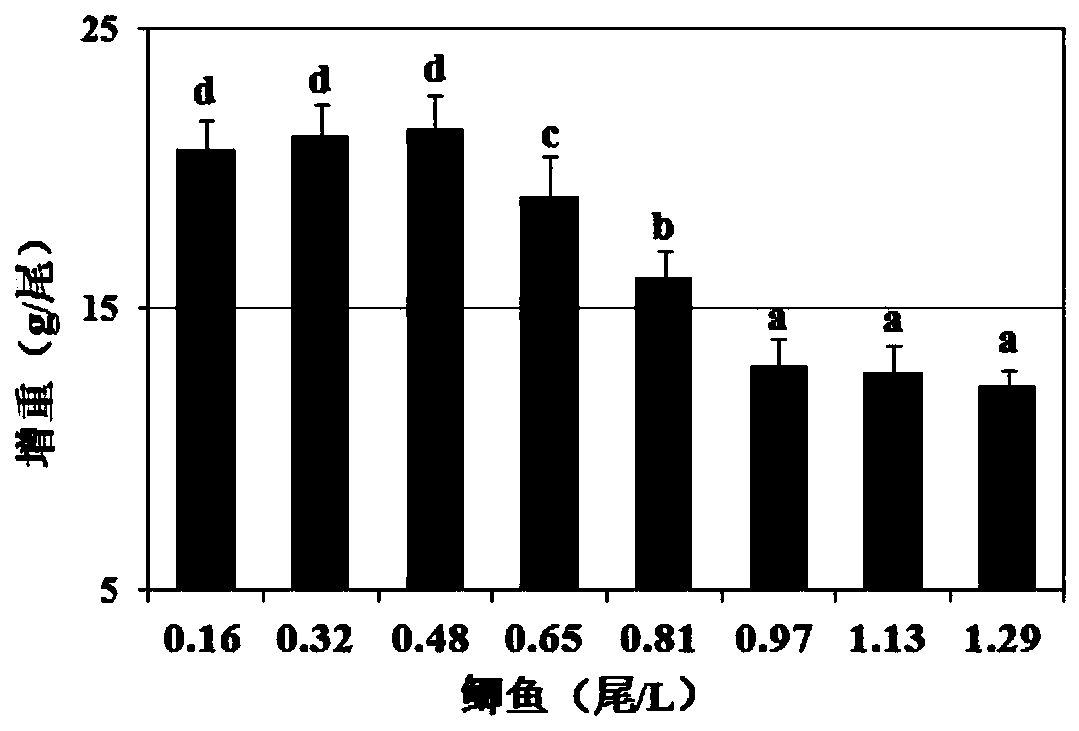

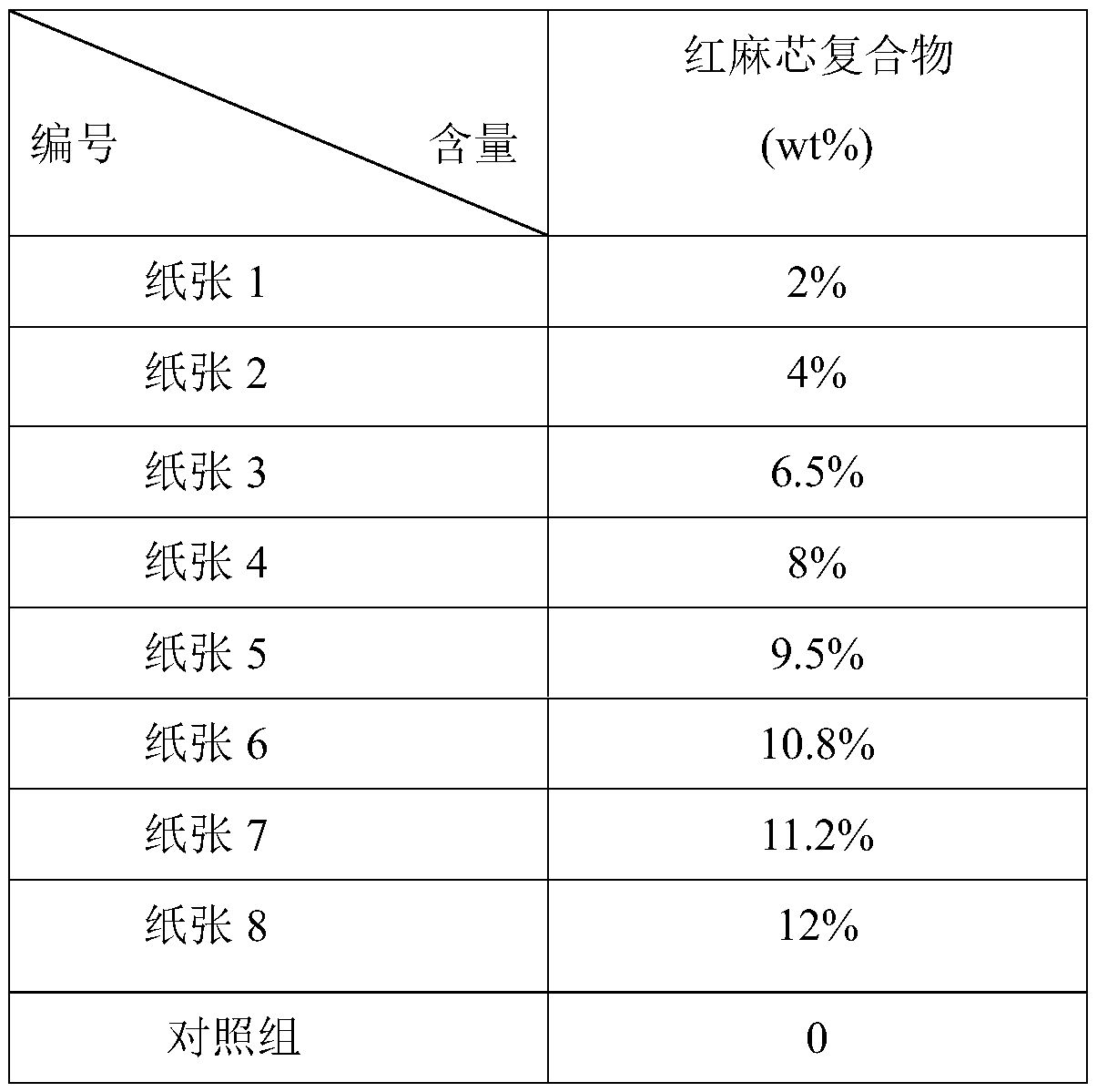

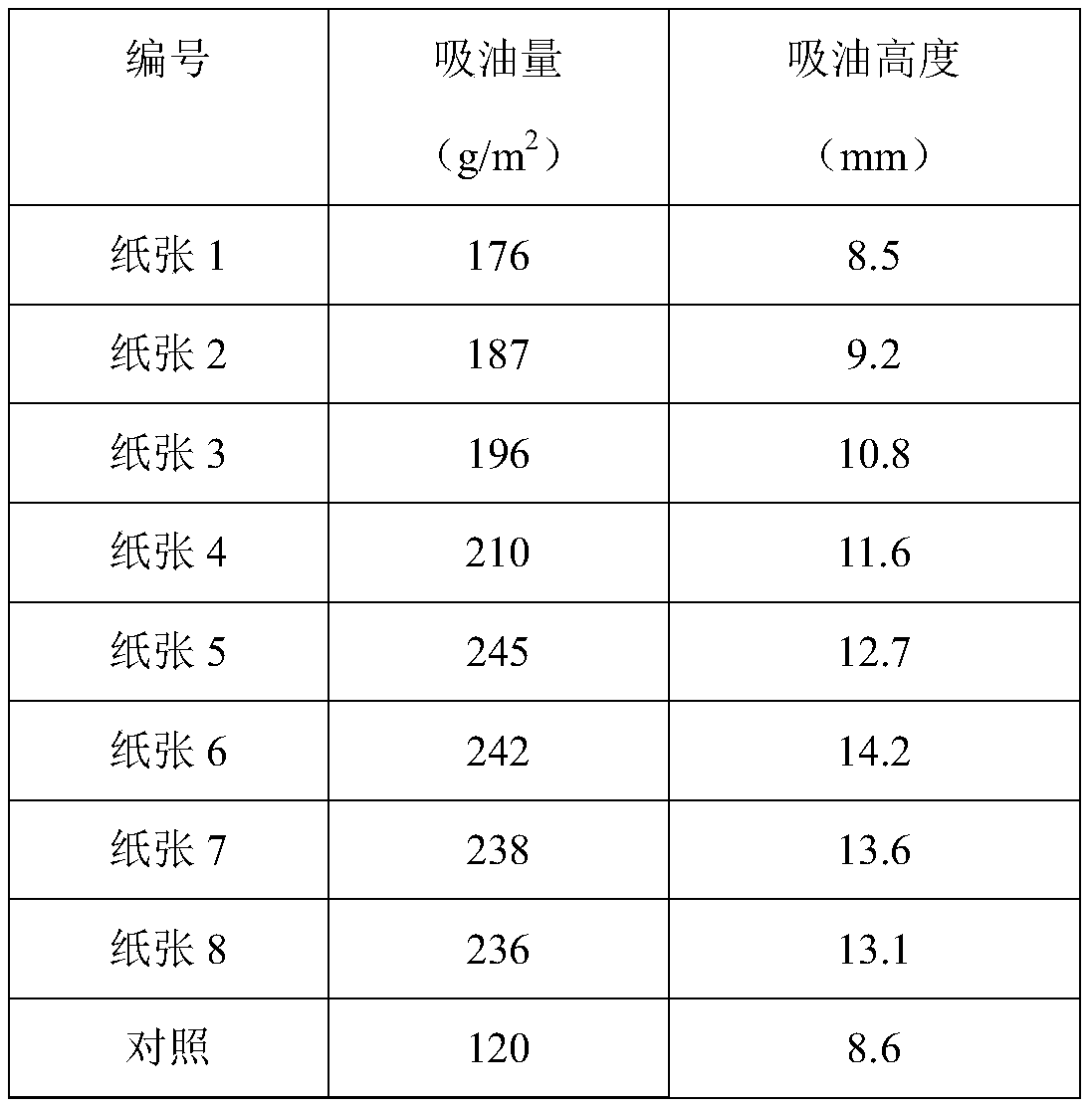

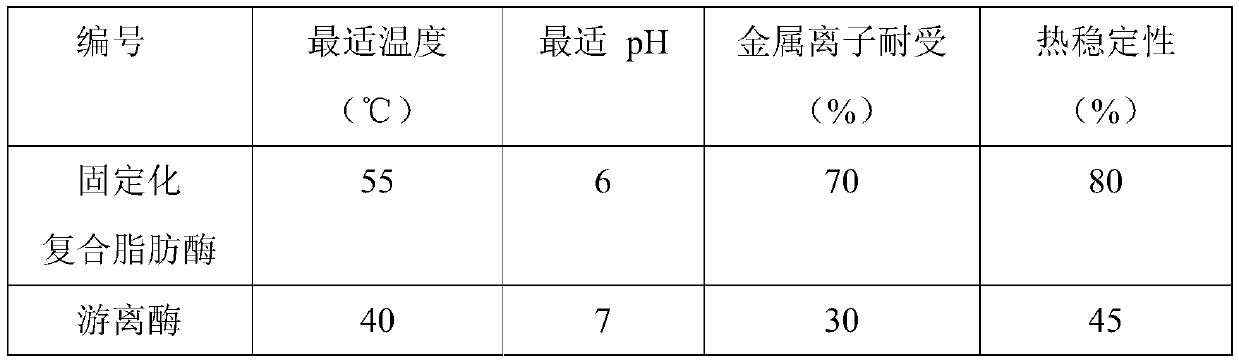

A kind of production method of tissue paper or kitchen paper and paper preparation method thereof

ActiveCN110820421BQuality assurancePick up the paper smoothlyHydrolasesMicroorganism/enzyme additionFiberPaper dust

The invention provides a production method of tissue paper or kitchen paper and a paper preparation method thereof. The paper is processed through initial drying, wet creping, secondary drying and winding. The paper is made of 20 parts of coniferous fibers. , 35 parts of bamboo fiber, 25 parts of bagasse fiber, 0.25wt% softener, 1.25wt% wet strength agent, 10.8wt% kenaf core mixture and 3.6% immobilized complex lipase, prepared by wet method Wrinkling is combined with a vacuum paper pickup device to wrinkle the paper to ensure the quality of the paper and the problem of paper dust. After adding modified kenaf core and immobilized complex lipase to the paper, and exploring the optimal addition amount, the kenaf core can improve the oil adsorption performance of the paper, and further ensure wet wrinkles and vacuum. The operation of picking up paper ensures the quality of the finished paper.

Owner:QUZHOU LONGYOU DOUBLE PANDA PAPER CO LTD

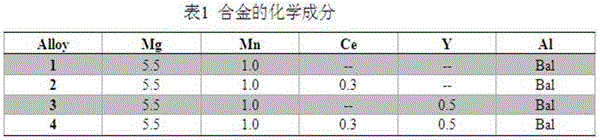

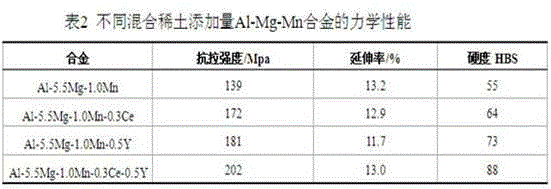

Al-Mg-Mn alloy containing rare earth elements Ce and Y, and preparation method thereof

The invention discloses a Al-Mg-Mn alloy containing rare earth elements Ce and Y. The Al-Mg-Mn alloy contains 5.5 mass% of Mg, 10 mass% of Mn, 0.3 mass% of Ce and 0.5 mass% of Y. The invention also discloses a preparation method of the alloy. The method is characterized in that Ce, Y and Mn elements are respectively added in Al-Mn, Al-Y and Al-Ce intermediate alloy forms, melting is carried out by adopting a crucible electric resistance furnace, the above crucible is a graphite crucible, and the method comprises the following steps: adding weighed industrial pure aluminum and a covering agent to the resistance furnace, melting at 800DEG C, carrying out furnace opening cooling to 600DEG C, pressing a magnesium block by using a titanium cover, heating to 740DEG C, adding the intermediate alloys, uniformly stirring in the melting process, adding hexachloroethane, refining to remove gases, standing for 6min, removing slag, and casting.

Owner:熊绍红

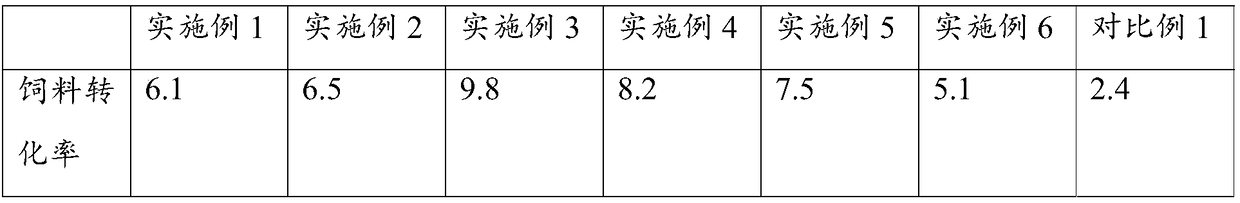

Feed partner as well as preparation method and application thereof and bioactive bacterial preparation prepared from same

InactiveCN109043127AImprove disease resistanceIncrease appetiteAnimal feeding stuffDiseaseHome environment

The invention provides a feed partner as well as a preparation method and application thereof and an active bacterial preparation prepared from same. The feed partner is mainly prepared by fermentingthe following components in parts by weight: 1 part of composite bacteria, 200 to 400 parts of starch, 40 to 60 parts of fish meal, 40 to 60 parts of bone powder, 5 to 15 parts of radix angelicae sinensis, 5 to 15 parts of poria cocos, 5 to 15 parts of radix astragali, 5 to 15 parts of rhizoma Chuangxiong, 5 to 15 parts of radix polygoni multiflori, 5 to 15 parts of radix codcnopsitis pilosulas, 0.5 to 0.6 part of composite vitamins, and 400 to 650 parts of liquid, wherein the liquid is one or more of water, milk and goat milk. By adopting the feed partner, the disease resistance of a pet canbe improved, the digestion capacity can be improved, the appetite of the pet can be improved, the pet food conversion rate can be improved, the odor of the pet manure can be apparently reduced, the pet manure is even odorless, the pathogenic bacteria in home environment can be greatly reduced, and the air is fresh.

Owner:赵华

Preparation method of low-carbon asphalt mixture

ActiveCN101837603BReasonable dosageOptimum Oil QuantityCeramic shaping apparatusPavement engineeringMaterials science

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

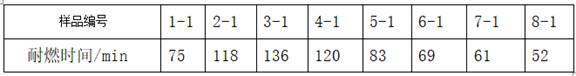

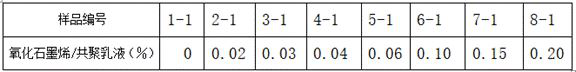

Preparation method of graphene high-performance fireproof coating

PendingCN113502077AGood insulation performanceMature technologyFireproof paintsMethacrylatePentaerythritol

The invention discloses a preparation method of a graphene high-performance fireproof coating, and the graphene high-performance fireproof coating is prepared from the following main raw materials: a copolymer emulsion, ammonium polyphosphate, melamine, pentaerythritol, graphene oxide, a coalescing agent, a dispersing agent, a defoaming agent, a flatting agent, titanium dioxide, deionized water and the like. Compared with other preparation processes, the process is mature, Aa methacrylate-vinylidene chloride copolymer emulsion, melamine, ammonium polyphosphate, pentaerythritol and various assistants are adopted as raw materials, the coating is prepared under certain technological conditions, the technology for preparing the graphene high-performance fireproof coating by using the copolymer emulsion in a laboratory is completed, and through a multi-data contrast test, the good addition amount of the graphene oxide in the high-performance fireproof coating is obtained, the test work of the laboratory on the main performance of the graphene fireproof coating is completed, and the test result shows that the developed graphene fireproof coating is excellent in fireproof performance and has a very good fireproof effect.

Owner:SHAOGUAN LIANBANG ENVIRONMENTALLY FRIENDLY NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com