Special niobium and vanadium containing chilled cast iron roll for splitting rack and production technology

A technology of chilled cast iron and rolls, which is applied in the field of chilled cast iron rolls and production technology for niobium-containing and vanadium-containing cutting frames. It can solve the problems of poor wear resistance of bainite balls, many precious alloys, and difficult turning, and achieve High tensile strength, improved purity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

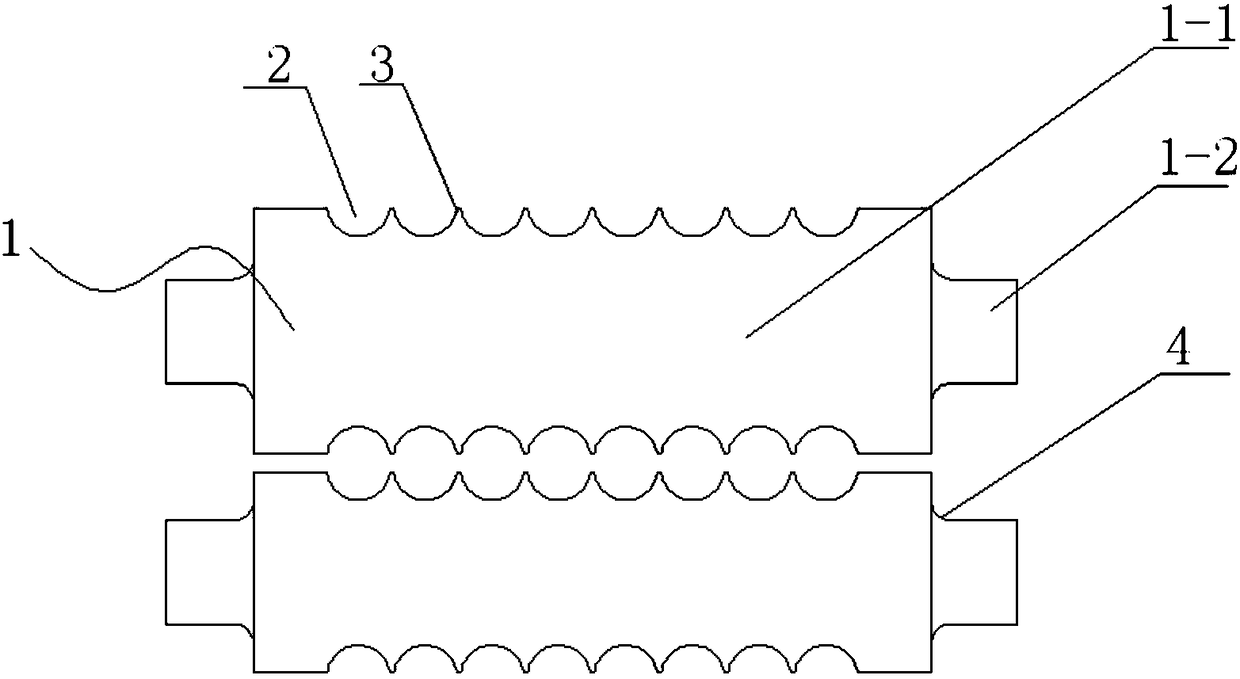

Image

Examples

Embodiment 1

[0031] The invention is a chilled cast iron roll specially used for a split frame containing niobium and vanadium, and the production steps of the roll are as follows:

[0032] Step 1. Preparation of chemical composition: The chemical composition of the outer layer of the preparation roll is: C: 2.9%, Si: 0.3%, Mn: 0.2%, P: 0.01%, S: 0.01%, Cr: 0.5%, Ni: 3.5%, Mo: 0.4%; V: 0.2%, Nb: 0.2%, the rest is Fe; the chemical composition of the prepared core is: C: 3.3%, Si: 2.3%, Mn: 0.4%, P: 0.01%, S: 0.01% , Cr: 0.15%, Mg: 0.01%, and the rest is Fe;

[0033] Step 2. Smelting: Melt the outer layer and core material of the roll through two electric furnaces respectively. After the temperature of the outer layer of molten iron reaches 1420°C, heat it for 5 minutes and then release it to the ladle. Add 1kg of heavy rare earth modifier per ton into the ladle. The dosage is pre-added with yttrium-based heavy rare earth modifier. When the temperature of the molten iron reaches 1450°C, pou...

Embodiment 2

[0042] The invention is a chilled cast iron roll specially used for a split frame containing niobium and vanadium, and the production steps of the roll are as follows:

[0043] Step 1. Preparation of chemical composition: The chemical composition of the outer layer of the preparation roll is: C: 3%, Si: 0.5%, Mn: 0.4%, P: 0.01%, S: 0.01%, Cr: 0.6%, Ni: 3.8%, Mo: 0.5%; V: 0.2%, Nb: 0.3%, the rest is Fe; the chemical composition of the prepared core is: C: 3.3%, Si: 2.3%, Mn: 0.4%, P: 0.01%, S: 0.01% , Cr: 0.15%, Mg: 0.02%, and the rest is Fe;

[0044] Step 2. Smelting: Melt the outer layer and core material of the roll through two electric furnaces respectively. After the temperature of the outer layer of molten iron reaches 1600°C, heat it for 5 minutes and then release it to the ladle. Add 2kg of heavy rare earth modifier per ton into the ladle. Add the yttrium-based heavy rare earth modifier in advance, when the temperature of the molten iron drops to 1500°C, pour the molte...

Embodiment 3

[0050] The invention is a chilled cast iron roll specially used for a split frame containing niobium and vanadium, and the production steps of the roll are as follows:

[0051] Step 1. Preparation of chemical composition: The chemical composition of the outer layer of the preparation roll is: C: 3.2%, Si: 0.4%, Mn: 0.5%, P: 0.01%, S: 0.01%, Cr: 0.8%, Ni: 3.8%, Mo: 0.4%; V: 0.2%, Nb: 0.2%, the rest is Fe; the chemical composition of the prepared core is: C: 3.3%, Si: 2.4%, Mn: 0.4%, P: 0.01%, S: 0.01% , Cr: 0.15%, Mg: 0.01%, and the rest is Fe;

[0052] Step 2. Smelting: Melt the outer layer and core material of the roll through two electric furnaces respectively. After the temperature of the outer layer of molten iron reaches 1600°C, heat it for 5 minutes and then release it to the ladle. Add 3kg of heavy rare earth modifier per ton into the ladle. Add the yttrium-based heavy rare earth modifier in advance, when the temperature of the molten iron drops to 1500°C, pour the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com