Preparation method of low-carbon asphalt mixture

A mixture and carbon asphalt technology, which is applied in the field of low-carbon asphalt mixture preparation, can solve the problems of reducing carbon dioxide, lowering asphalt mixture mixing temperature and paving temperature, and large emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of low-carbon asphalt mixture AC-13 (without adding fiber stabilizer)

[0035] (1) Testing of the performance of low-carbon agent modified asphalt, selection of aggregates and gradation

[0036] In this example, the content of low carbon agent is 3%, and the binder is 70# base asphalt. The required 70# base asphalt is required to meet the relevant requirements of "Technical Specification for Highway Asphalt Pavement Construction" (JTG F40-2004). First, the basic properties of the modified asphalt mixed with low-carbon agent were tested, and the test results are shown in Table 1.

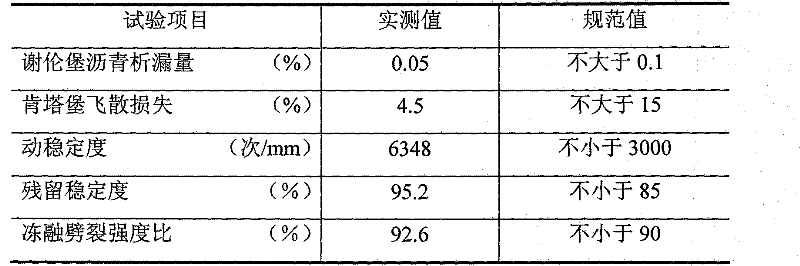

[0037] Table 1 Basic performance test results of 70# base asphalt + 3% low carbon agent

[0038]

[0039]

[0040] The coarse aggregate used is basalt, and the fine aggregate is limestone, all of which meet the relevant requirements of "Technical Specification for Highway Asphalt Pavement Construction" (JTG F40-2004). For this example, the gradation used is shown...

Embodiment 2

[0063] Example 2: Preparation of Low Carbon Asphalt Mixture SMA-13 (Adding Fiber Stabilizer)

[0064] (1) Testing of the performance of low-carbon agent-modified asphalt, selection of fiber stabilizers, aggregates and gradation

[0065] In this example, the content of low-carbon agent is 5%, and the binder is SBS modified asphalt. The selected SBS modified asphalt is required to meet the relevant requirements of "Technical Specification for Highway Asphalt Pavement Construction" (JTG F40-2004). First, the basic properties of the modified asphalt mixed with low-carbon agent were tested, and the test results are shown in Table 6.

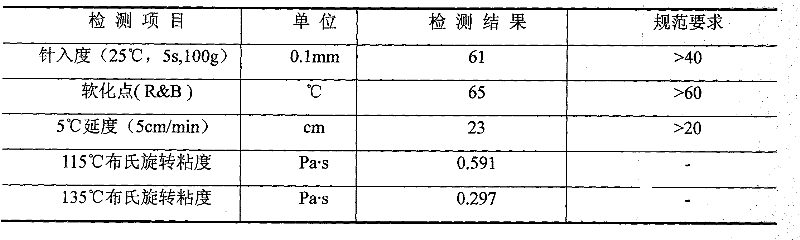

[0066] Table 6 Basic performance test results of SBS modified asphalt + 5% low carbon agent

[0067]

[0068]

[0069] The coarse aggregate used is diabase, the fine aggregate is limestone, and the filler is ore powder obtained by grinding limestone material. After inspection, they all meet the relevant requirements of "Technical Specificati...

Embodiment 3

[0082] Example 3: Preparation of low carbon asphalt mixture OGFC-13

[0083] (1) Testing of the performance of low-carbon agent modified asphalt, selection of aggregates and gradation

[0084] In this example, the content of low-carbon agent is 6.5%, and the binder is 70# base asphalt. The required 70# base asphalt is required to meet the relevant requirements of "Technical Specification for Highway Asphalt Pavement Construction" (JTG F40-2004). First, the basic properties of the modified asphalt mixed with low-carbon agent were tested, and the test results are shown in Table 11.

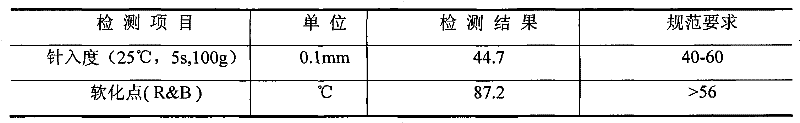

[0085] Table 11 Test results of basic performance of 70# base asphalt + 6.5% low carbon agent

[0086]

[0087] The target void ratio of the drainage road surface is generally set to 18% to 25%, and the target void ratio of this example is set to 20%. The purpose of selecting the preliminary test grading is to determine a reasonable grading that meets the target porosity under the preliminary t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com