Sea-buckthorn nutrient milk powder and preparation method thereof

A technology for sea buckthorn powder and milk powder, which is applied in milk preparations, dairy products, applications, etc., can solve problems such as reduced product yield, reduced production capacity, shortened tower washing cycle, etc. , the effect of enhancing sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

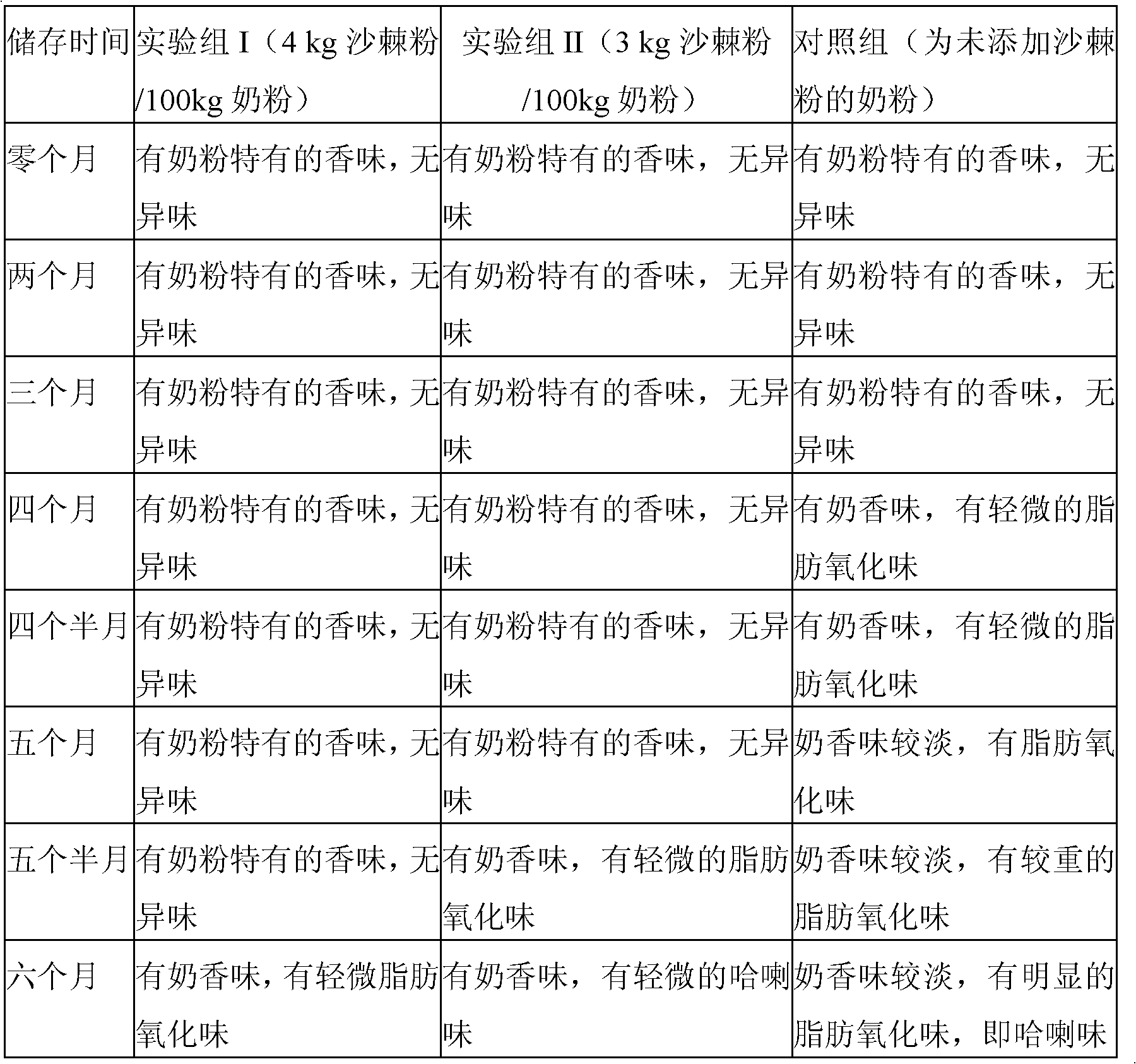

Embodiment 1

[0030] Embodiment 1 prepares seabuckthorn nutritional milk powder (100 kilograms)

[0031] Filter 100 kg of fresh milk that meets the inspection standards through a filter to remove impurities, somatic cells, etc. in the milk. Then heat the milk to 80°C and pasteurize it for 15 seconds. After sterilization, it is quickly cooled to 40°C and poured into a wet mixing tank. 1.1 kg of lactose is slowly poured into the mixer in sequence and proportion, and fully mixed with milk. Adjust the homogenization pressure at 10-15Mpa, and carry out high-pressure homogenization of the mixed milk through a high-pressure homogenizer. The homogenized feed liquid is concentrated and sterilized, using a three-effect process, with a sterilization temperature of ≥85°C and a sterilization time of 25 seconds. And during the concentration process, intermittently take samples from the return port, measure the concentration of the feed liquid with a Baume meter, and when the concentration of the feed li...

Embodiment 2

[0032]Embodiment 2 prepares seabuckthorn nutritional milk powder (100 kilograms)

[0033] Filter 100 kg of fresh milk that meets the inspection standards through a filter to remove impurities, somatic cells, etc. in the milk. Then heat the milk to 80°C and pasteurize it for 15 seconds. After sterilization, it is quickly cooled to 40°C and poured into a wet mixing tank. 1.0 kg of lactose is slowly poured into the mixer in sequence and proportion, and fully mixed with milk. Adjust the homogenization pressure at 10-15Mpa, and carry out high-pressure homogenization of the mixed milk through a high-pressure homogenizer. The homogenized feed liquid is concentrated and sterilized, using a three-effect process, with a sterilization temperature of ≥85°C and a sterilization time of 25 seconds. And during the concentration process, intermittently take samples from the return port, measure the concentration of the feed liquid with a Baume meter, and when the concentration of the feed liq...

Embodiment 3

[0034] Embodiment 3 prepares seabuckthorn nutritional milk powder (100 kilograms)

[0035] Filter 90 kg of fresh milk that meets the inspection standards through a filter to remove impurities, somatic cells, etc. in the milk. Then heat the milk to 80°C and pasteurize it for 15 seconds. After sterilization, it is quickly cooled to 40°C and poured into a wet mixing tank. 11 kg of lactose is slowly poured into the mixer in sequence and proportion, and fully mixed with milk. Adjust the homogenization pressure at 10-15Mpa, and carry out high-pressure homogenization of the mixed milk through a high-pressure homogenizer. The homogenized feed liquid is concentrated and sterilized, using a three-effect process, with a sterilization temperature of ≥85°C and a sterilization time of 25 seconds. And during the concentration process, intermittently take samples from the return port, measure the concentration of the feed liquid with a Baume meter, and when the concentration of the feed liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com