Process for preparing coenzyme Q10 by sphingosine unit cell strain fermentation, extraction and coupling

A technology for sphingomonas and sphingosine, which is applied in the field of coupling preparation of coenzyme Q10 by using sphingomonas fermentation and extraction, can solve the problems of easy destruction of coenzyme Q, large loss of extraction solvent, time-consuming and labor-intensive and the like. , to achieve the effect of simple and time-saving method, saving manpower and material resources, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

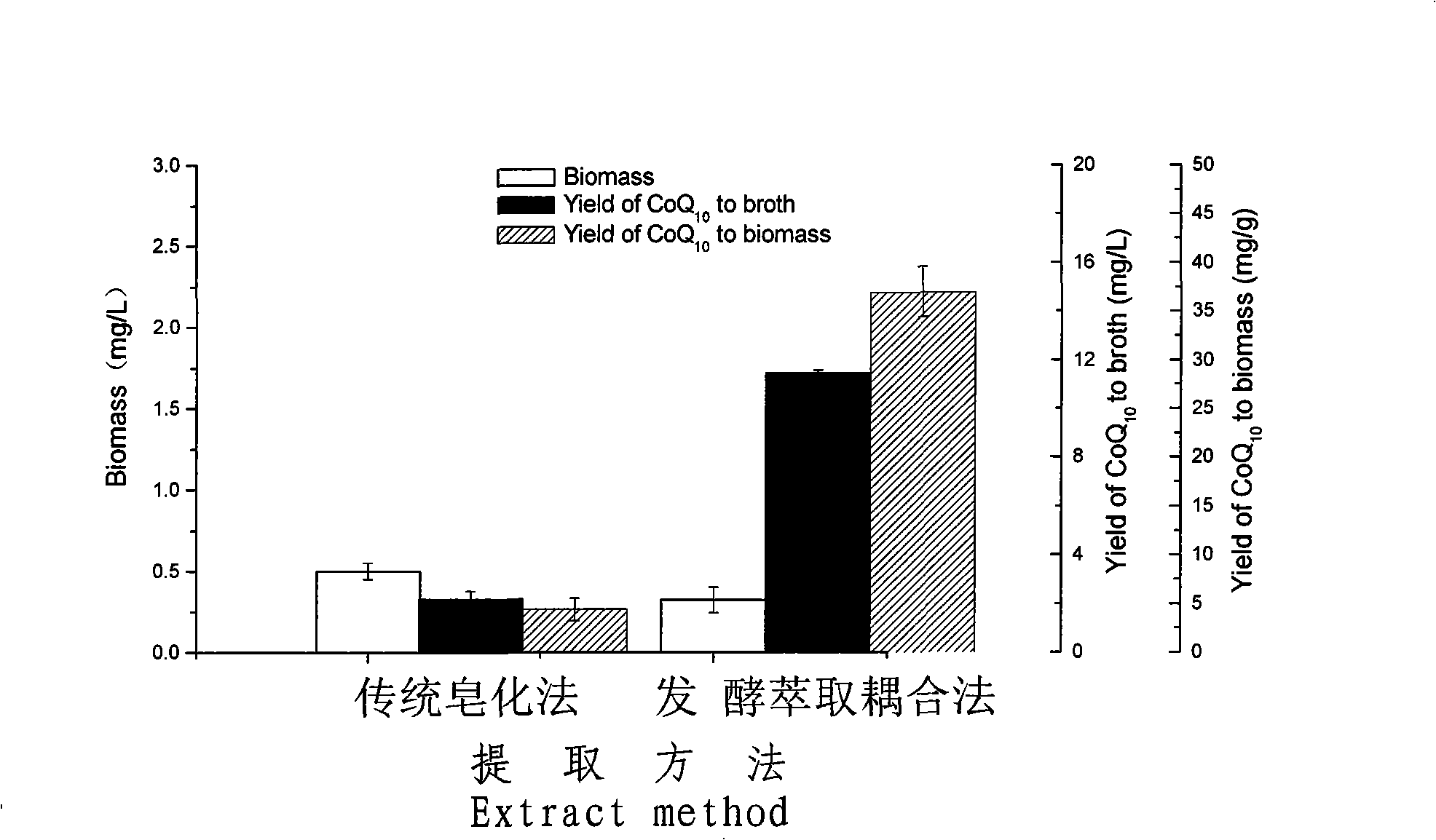

[0027] Example 1: Sphingomonas sp. (Sphingomonas sp.) ZUTE03 (CCTCC No. M207084) fermentation extraction coupled production of coenzyme Q 10 Process Validation

[0028] Production of Coenzyme Q by Fermentation-Extraction Coupled Method 10

[0029] Direct extraction of coenzyme Q produced by microbial fermentation by fermentation-extraction coupling method 10 There are two main problems to be solved: 1. Coenzyme Q 10 It is an intracellular product obtained by microbial fermentation, so it is necessary to choose a good cell permeabilizer to dissolve it from the cell, creating a prerequisite for the coupling extraction of fermentation extraction; 2. To select a suitable organic solvent to extract extracellular coenzyme Q 10 , to determine the optimal amount, optimal time and optimal extraction time of its addition, and the addition of this solvent has a significant effect on the growth of bacteria and coenzyme Q 10 output is not affected.

[0030] Therefore, the method is va...

Embodiment 2

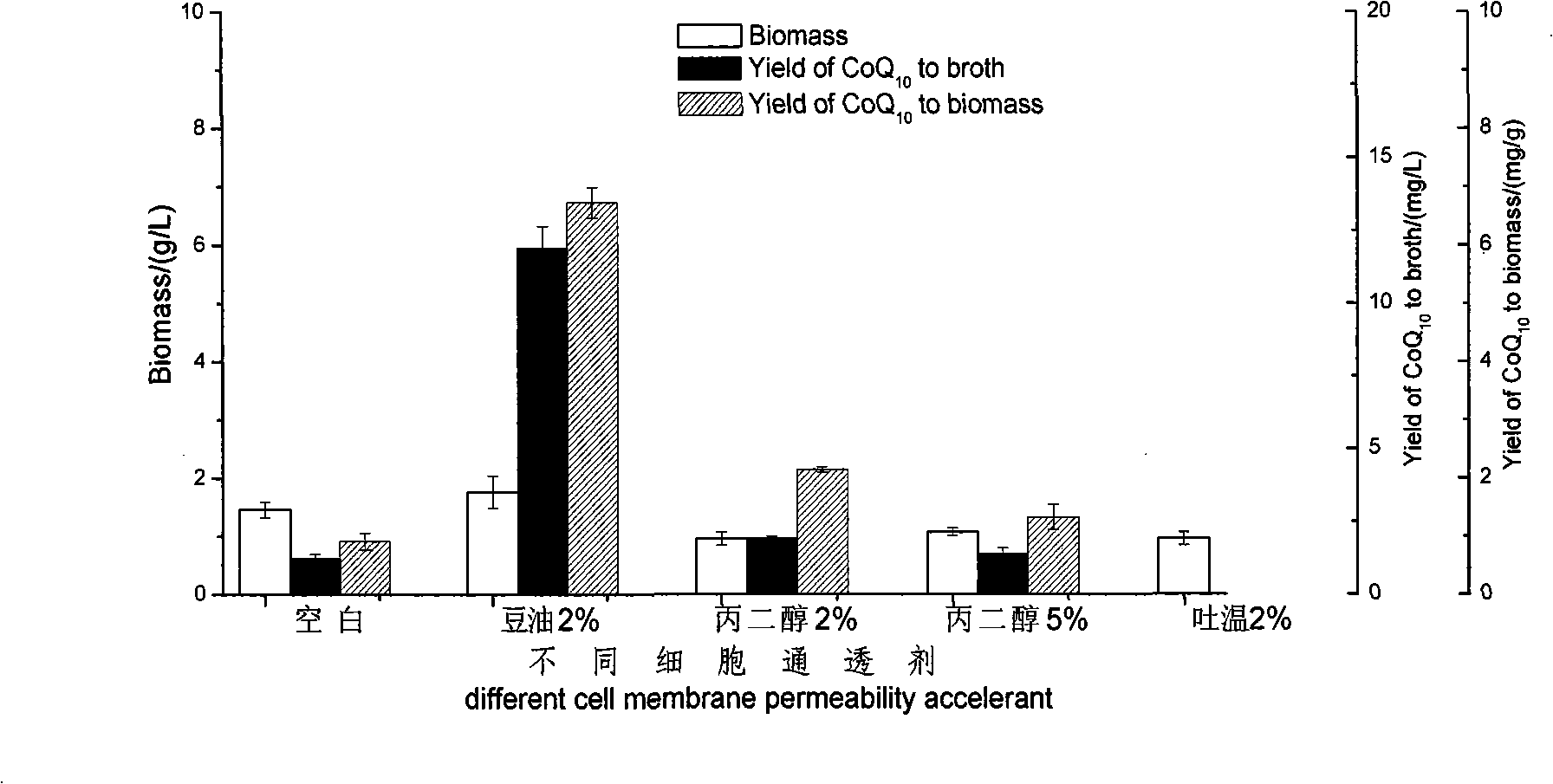

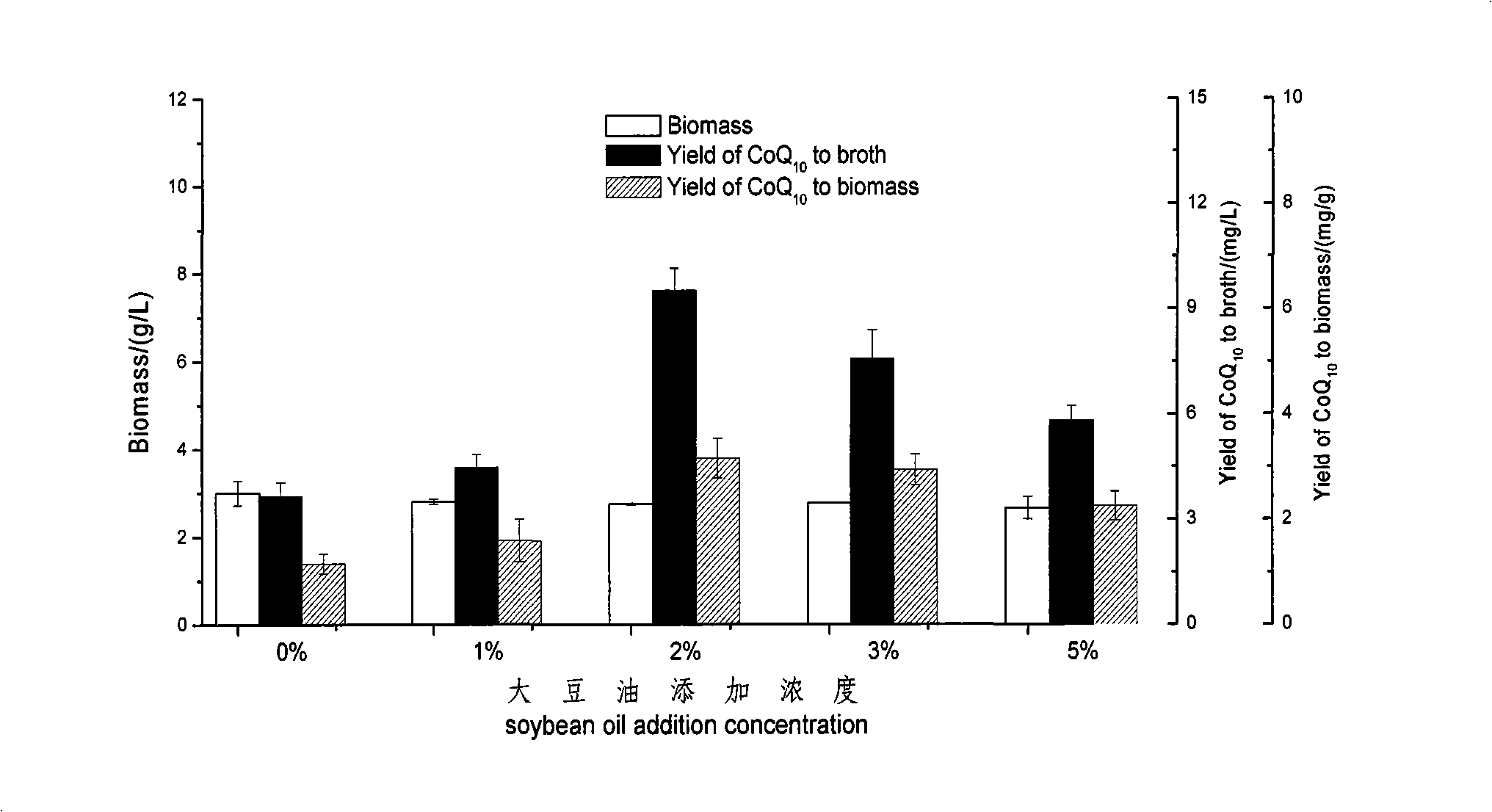

[0032] Example 2: Sphingomonas sp. (Sphingomonas sp.) ZUTE03 CCTCC No.M207084 Fermentation Extraction Coupled Production of Coenzyme Q 10 Optimization of process conditions

[0033] On the basis of confirming the results of Example 1 and combining the mechanism of fermentation-extraction coupling, various conditions were explored and optimized.

[0034] (1), selection of fermentation extraction coupling extraction solvent

[0035] Select n-hexane, acetone, propylene glycol, and olive oil as the fermentation extraction reagent, and use soybean oil as the cell permeabilizing agent in advance (addition concentration 1%, 1.5mL), add fermentation medium (glucose 15g, (NH 4 ) 2 SO 4 10g, KH 2 PO 4 0.5g, Na 2 HPO 4 1.5g, MgSO 4 0.5g, 1000ml of water (pH 7.0) 150mL, inoculate the sphingomonas (Sphingomonas sp.) ZUTE03 (CCTCC No.M 207084) bacterial suspension (cell concentration 1.94g / L) at 4% (v / v) Amount, inoculated in the fermentation medium, culture temperature 25°C, 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com