Formula for enhancing mold corrosion resistance of wheat straw/PP (polypropylene) wood-plastic composite material by using antimicrobial agent

A wood-plastic composite material, wheat straw technology, applied in the direction of weather resistance / light resistance / corrosion resistance, analytical materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

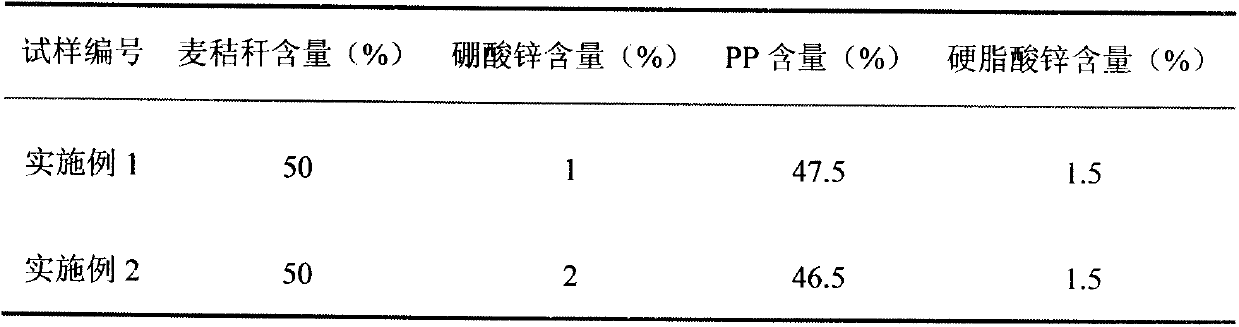

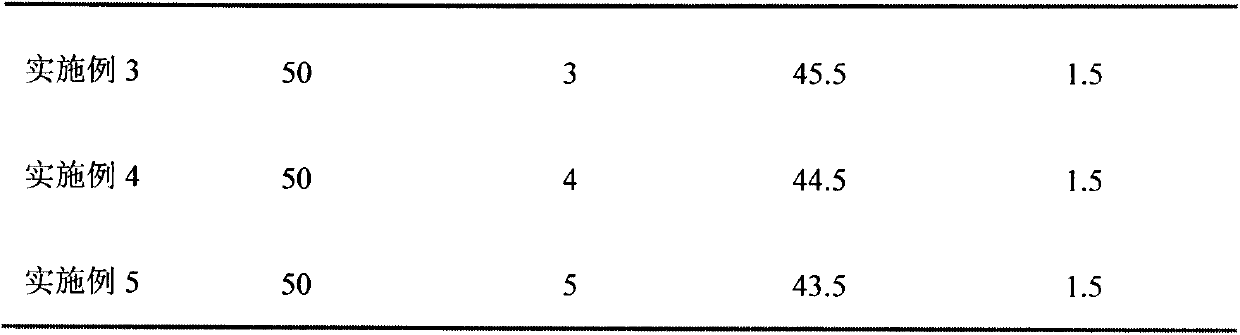

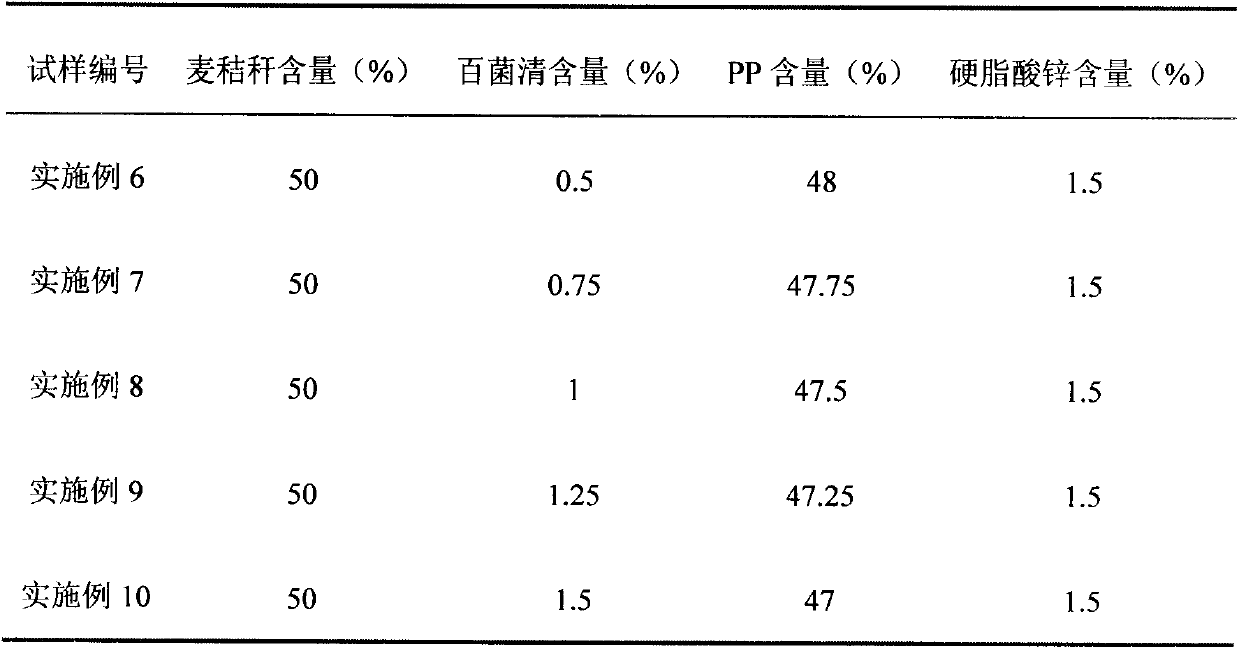

Examples

Embodiment Construction

[0013] The preparation of wood-plastic composite material is carried out according to the following steps:

[0014] Step 1: Dry the recovered wheat straw naturally and then remove impurities to make it free from mildew, impurities and agglomerates, crush and screen the wheat straw to obtain the particle size required for the experiment: 60 mesh.

[0015] Step 2: Dry the wheat straw powder with a particle size of 60 mesh, and use KH550 to surface treat the wheat straw powder. The dosage of KH550 is 2% of the mass of the wheat straw powder; Mix the wheat straw powder and additives fully and evenly; take the above-mentioned processed wheat straw powder and appropriate amount of PP film and mix them in an open rubber mixer. The temperature of the front drum is 175°C, and the temperature of the rear drum is 170°C. The mixing time is 5 minutes; after the material is mixed evenly, put it into a flat vulcanizing machine for molding, the molding temperature is 180°C, the pressure is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com