Efficient DLP photosensitive resin with flame retardant property

A technology of photosensitive resin and flame retardant performance, applied in the field of high-efficiency DLP photosensitive resin, can solve the problems of unusable and restricted development, and achieve the effects of reducing time cost, less environmental pollution, and high printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

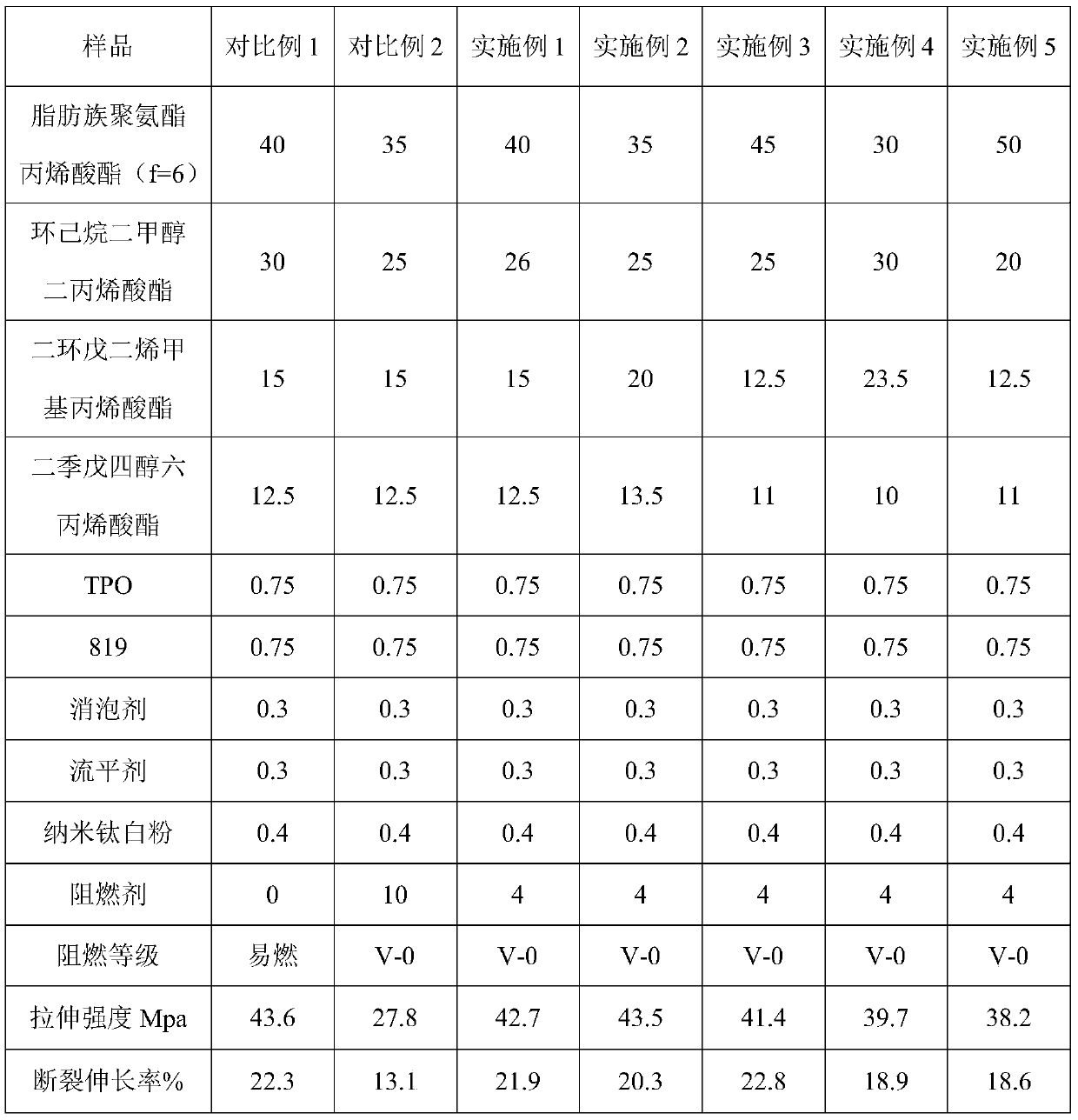

comparative example 1

[0033] In terms of mass percentage, weigh aliphatic urethane acrylate (functionality is 6): 40, cyclohexane dimethanol diacrylate: 30, dicyclopentadiene methacrylate: 15, dipentaerythritol hexaacrylate 12.5 , TPO (2,4,6-trimethylbenzoyl-diphenylphosphine oxide): 0.75, 819 (phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide): 0.75, Leveling agent: 0.3, defoamer: 0.3, nano-titanium dioxide: 0.4, after mixing all the materials together, stir in the mixer at a speed of 1800r / min for 2h, after the dispersion is uniform, ultrasonic 1~2h, until the bubbles are completely Disappear and start printing after cooling to room temperature.

[0034] The wavelength of the selected equipment is 405nm, and the light-mechanical intensity is 7000uw / cm 2 , single-layer curing time 1.5s, flammable.

comparative example 2

[0036] In terms of mass percentage, weigh aliphatic polyurethane acrylate (functionality is 6): 35, cyclohexane dimethanol diacrylate: 25, dicyclopentadiene methacrylate: 15, dipentaerythritol hexaacrylate 12.5 , TPO (2,4,6-trimethylbenzoyl-diphenylphosphine oxide): 0.75, 819 (phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide): 0.75, Leveling agent: 0.3, defoamer: 0.3, nano-titanium dioxide: 0.4, flame retardant A: 10, after mixing all the materials together, stir in a mixer at a speed of 1800r / min for 2 hours, after the dispersion is uniform, ultrasonic 1~2h, until the bubbles completely disappear, and start printing after cooling to room temperature.

[0037] The wavelength of the selected equipment is 405nm, and the light-mechanical intensity is 7000uw / cm 2 , the single-layer curing time is 1.7s, the flame retardant grade has reached V-0, and the mechanical properties of the material are poor.

Embodiment example 1

[0039] In terms of mass percentage, weigh aliphatic polyurethane acrylate (functionality is 6): 40, cyclohexane dimethanol diacrylate: 26, dicyclopentadiene methacrylate: 15, dipentaerythritol hexaacrylate 12.5 , TPO (2,4,6-trimethylbenzoyl-diphenylphosphine oxide): 0.75, 819 (phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide): 0.75, Leveling agent: 0.3, defoamer: 0.3, nano-titanium dioxide: 0.4, flame retardant A: 4, after mixing all the materials together, stir in a mixer at a speed of 1800r / min for 2 hours, and after the dispersion is uniform, ultrasonic 1~2h, until the bubbles completely disappear, and start printing after cooling to room temperature.

[0040] The wavelength of the selected equipment is 405nm, and the light-mechanical intensity is 7000uw / cm 2 , the single-layer curing time is 1.5s, and the flame retardant grade has reached V-0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com