Preparation method of graphene high-performance fireproof coating

A kind of technology of fireproof coating and graphene, applied in fireproof coating, coating and other directions, can solve problems such as affecting the effect of polymer modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

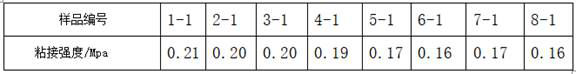

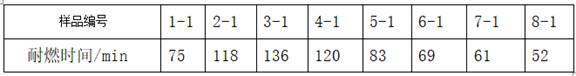

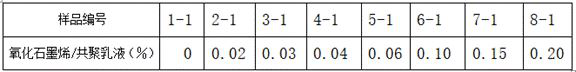

Examples

Embodiment 1

[0023] A method for preparing a graphene high-performance fireproof coating, comprising the following main raw materials: copolymer emulsion, ammonium polyphosphate, melamine, pentaerythritol, graphene oxide, film-forming aids, dispersants, defoamers, leveling agents, titanium dioxide and deionized water, etc., including the following steps:

[0024] S1. According to the design requirements, a certain ratio of graphene oxide suspension is evenly added to the copolymer emulsion, and ultrasonic vibration equipment is used for mixing, and the graphene oxide suspension and copolymer emulsion are made into a mixed emulsion, and melamine and pentaerythritol are added to mix;

[0025] S2. Add ammonium polyphosphate, titanium dioxide, dispersant and deionized water into the grinder for high-speed stirring and grinding, and then pour the prepared solution into a beaker for use;

[0026] S3, adding the prepared solution into the mixed emulsion of copolymer emulsion and graphene oxide, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com