Method for efficiently immobilizing heavy metals in sludge incineration residues by preparing geopolymer

A geopolymer and sludge incineration technology, applied in the field of resources and environment, can solve the problems of heavy metal waste exceeding its own volume, poor mechanical properties of cement containing sludge incineration residue, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

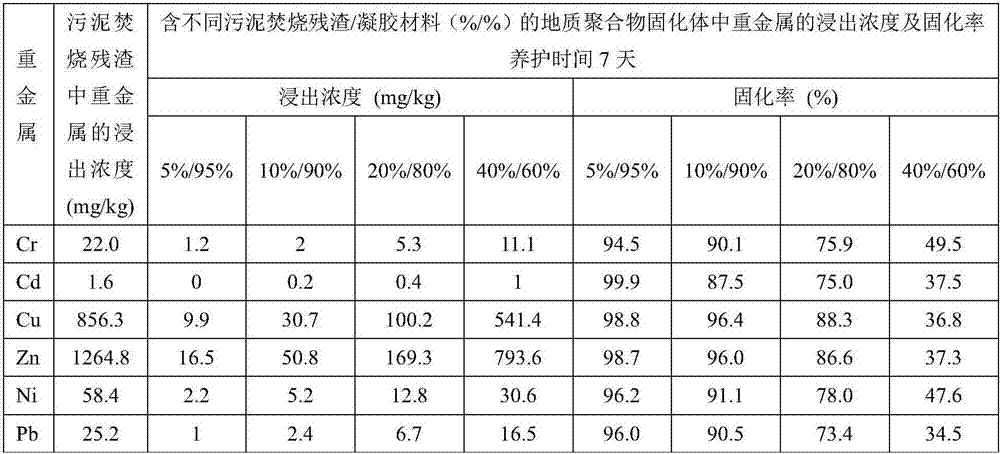

[0039] Example 1 A method for efficiently immobilizing heavy metals in sludge incineration residues by preparing geopolymers

[0040] Using metakaolin as the gel material and water glass as the alkali activator, the mass ratio of sludge incineration residue to gel material is 5%: 95%, and the mass ratio variation range of the water glass amount to the mixture of metakaolin and residue is 0.81, prepared geopolymer, and the variation range of water glass modulus is 1.2. Among them, metakaolin, water glass, and sludge incineration residue are mixed by physical methods.

Embodiment 2

[0041] Example 2 A method for efficiently immobilizing heavy metals in sludge incineration residues by preparing geopolymers

[0042] Using metakaolin as the gel material and water glass as the alkali activator, the mass ratio of sludge incineration residue to gel material is 10%:90%, and the mass ratio variation range of water glass amount to metakaolin and residue mixture is 0.81, prepared geopolymer, and the variation range of water glass modulus is 1.2. Among them, metakaolin, water glass, and sludge incineration residue are mixed by physical methods.

Embodiment 3

[0043] Example 3 A method for efficiently immobilizing heavy metals in sludge incineration residues by preparing geopolymers

[0044] Using metakaolin as the gel material and water glass as the alkali activator, the mass ratio of sludge incineration residue to gel material is 5%: 95%, and the mass ratio variation range of the water glass amount to the mixture of metakaolin and residue 0.81, prepared geopolymer, the range of water glass modulus is 1.3. Among them, metakaolin, water glass, and sludge incineration residue are mixed by physical methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com