Preparation method and application of GO-TA/waterborne epoxy composite coating

A GO-TA and composite coating technology, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor corrosion resistance and limited application in anti-corrosion fields, and achieve good stability, simple and feasible preparation process, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of GO-TA / waterborne epoxy composite coating comprises the following steps.

[0029] (1) Preparation of base material.

[0030] Weigh the water-based epoxy resin and curing agent to mix, stir until the solution is uniform, and obtain a uniformly mixed base material.

[0031] (2) Preparation of GO-TA dispersion.

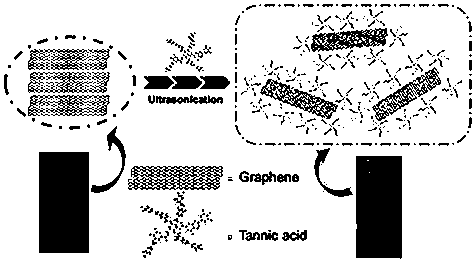

[0032] Add 100mL deionized water and 0.05g tannic acid (TA) into a 250mL beaker, and oscillate ultrasonically for 20min. Then, add 0.1g graphene under ultrasonic vibration (600W) and disperse in the above tannic acid solution for 1 hour to obtain Ta intercalated graphene dispersion, and finally remove it by high-speed centrifuge (1000r / min-1500r / min) The unreacted graphene and tannic acid in the solution were mixed, and then the GO-TA dispersion was obtained.

[0033] (3) Preparation of graphene waterborne epoxy composite coating

[0034] Weigh the base material and GO-TA dispersion solution and mix, stir to form a uniform dispersion sys...

experiment example 2

[0039] Mix 0.5%, 0.7%, and 1.0% GO-TA dispersions with waterborne epoxy resin, and disperse them ultrasonically for 1 hour to prepare 0.5% GO-TA / waterborne epoxy coatings and 0.7% GO-TA / waterborne epoxy coatings, respectively. and 1% GO-TA / water-based epoxy paint, and then move them into the spray gun and spray evenly on the sandblasted and welded substrate steel sheet (P110). It is carried out within 1 hour. After the spraying is completed, the coated steel sheet is cured at room temperature for 2 days to obtain a sample coating. Pure water-based epoxy resin is used as a control.

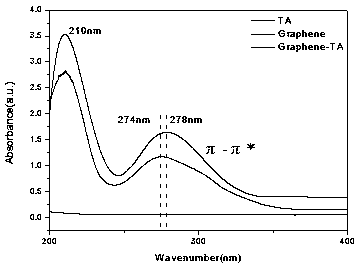

[0040] (1) The stability of GO-TA dispersion solution was observed by static method. see attached results figure 2 , it can be observed from the figure that the unmodified GO material completely settled in the aqueous solution for 2-3 hours, while the GO-TA dispersion solution did not settle after standing for 30 days, and the dispersion was relatively uniform, indicating that the GO-TA dispersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com