Glycidyl ether modified urea formaldehyde resin and preparation method thereof

A technology of glycidyl ether and urea-formaldehyde resin, applied in aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve problems such as applications that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

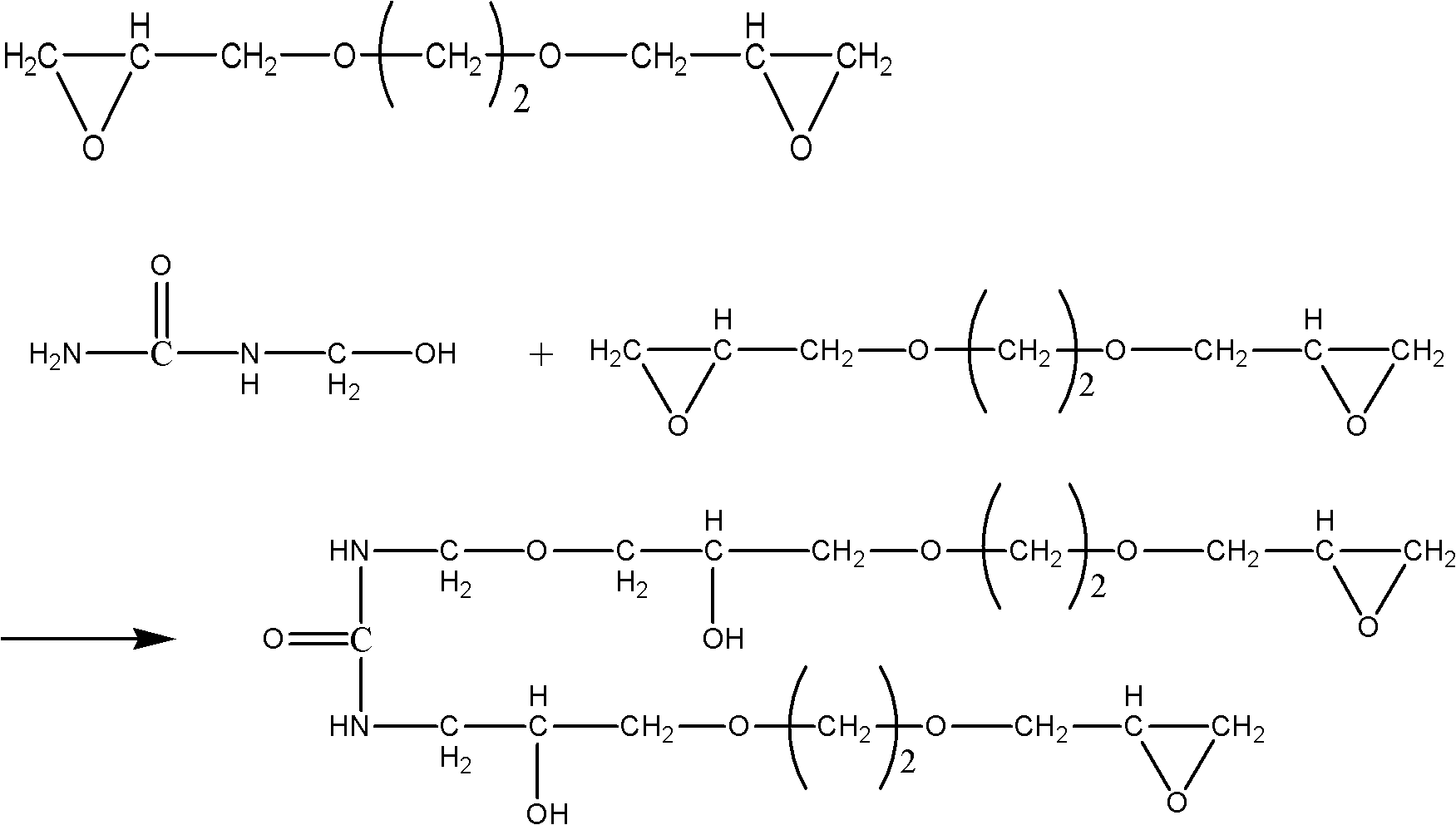

Method used

Image

Examples

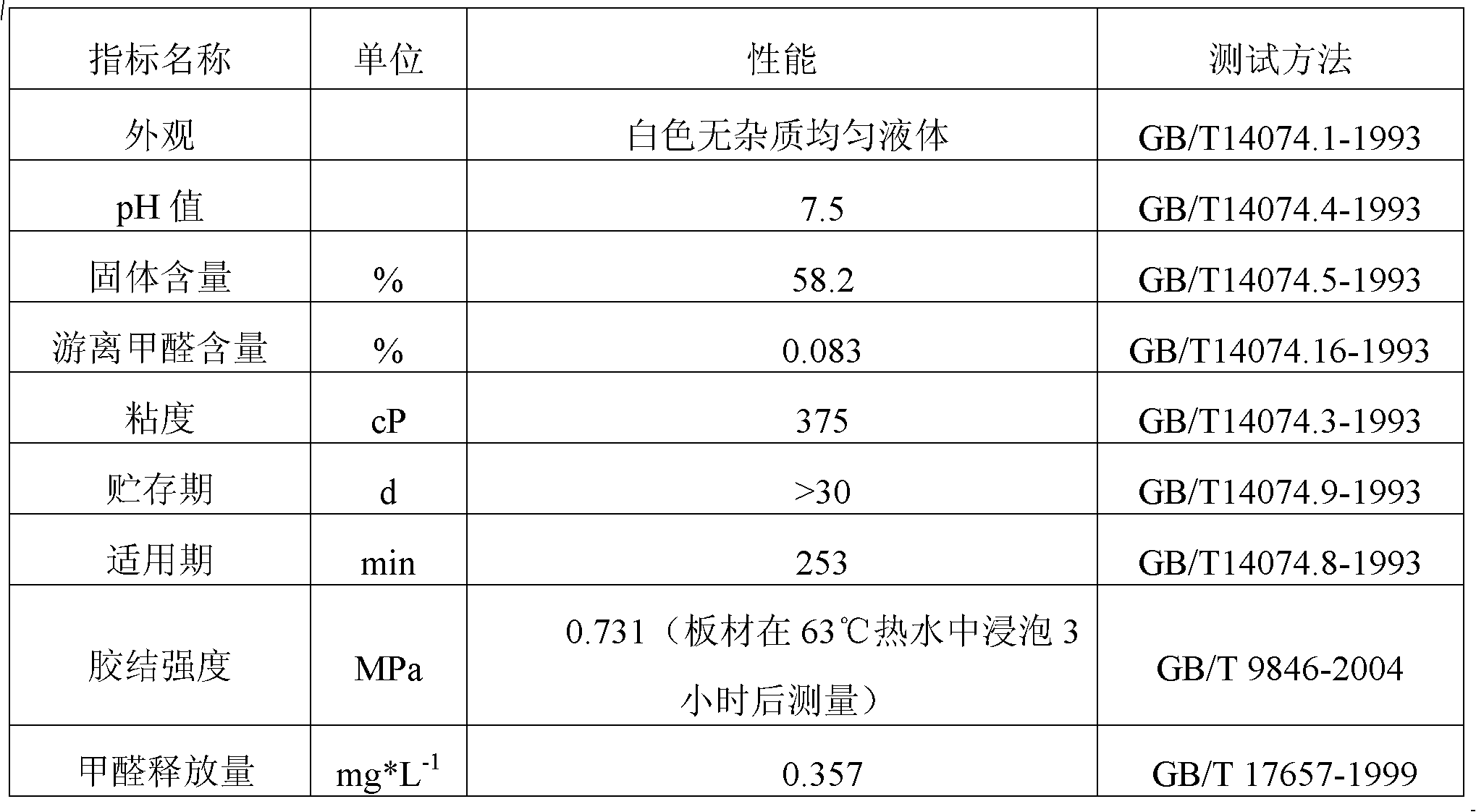

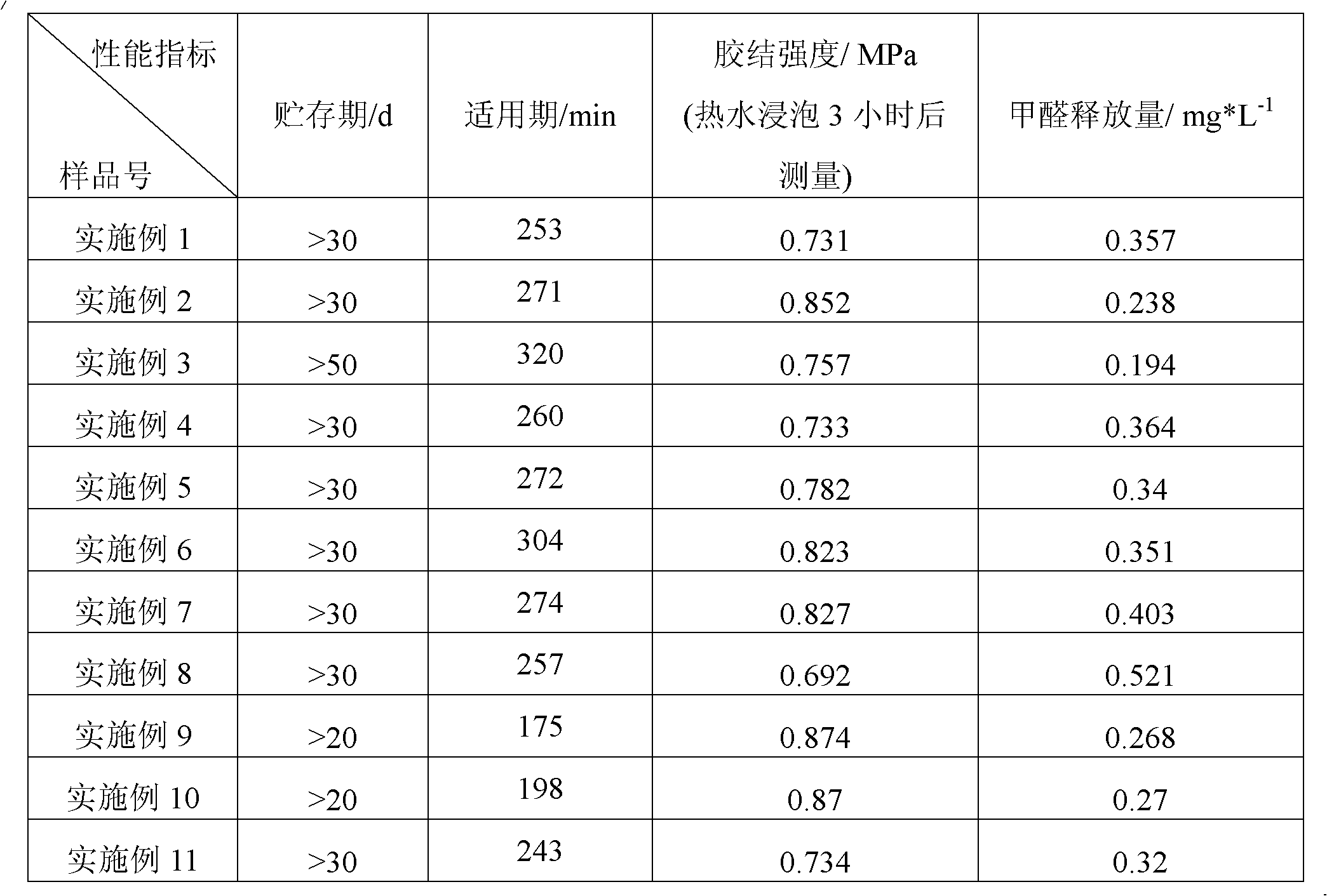

Embodiment 1

[0019] Preparation of urea-formaldehyde resin: In another 500ml four-necked bottle, open the reflux condensing device and the stirring device, add 170g of formaldehyde solution with a mass percentage of 37%, 70.00g of urea, 1.0g of modifier borax, and add aqueous sodium hydroxide solution to adjust the pH of the system = 8.5, start heating at the same time; when the temperature rises to 90°C, heat-preserve for 50 minutes; adjust the pH of the system to 5.0 with aqueous formic acid, add 10 g of ethylene glycol diglycidyl ether, and heat-react for 10 minutes at 90°C; add 30 parts by weight of urea, Insulate and react at 85°C for 20 minutes; adjust the pH value to 7.2 with aqueous sodium hydroxide solution, add 20 g of urea, and insulate and react at 70°C for half an hour; cool down to 40°C, add aqueous sodium hydroxide solution to adjust the pH value of the system to 8.0, cool and discharge , to obtain urea-formaldehyde resin. The total molar ratio of formaldehyde and urea in th...

Embodiment 2

[0022] In this embodiment, 30 g of ethylene glycol diglycidyl ether is added to modify the urea-formaldehyde resin during the preparation process, and the others are the same as in Example 1.

Embodiment 3

[0024] In this embodiment, 50 g of ethylene glycol diglycidyl ether is added to modify the urea-formaldehyde resin during the preparation process, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com