Dyeing and finishing process of pure-flax Huashu textile fabric

A fabric and linen technology, which is applied in textiles and papermaking, biochemical fiber treatment, bleaching products, etc., can solve the problems of flax fiber damage, etc., and achieve the effects of small loss of strength, elimination of itching, good drapability and skin-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A kind of dyeing and finishing method of pure linen Huashu spinning fabric:

[0046] Preparation of raw materials Pure linen fabric L 21*21 / 60*53; L 17*21 / 60*53

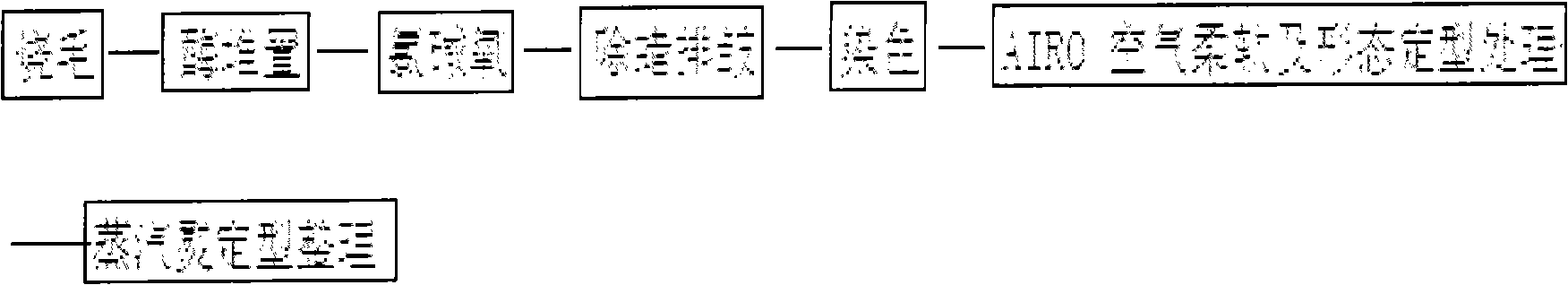

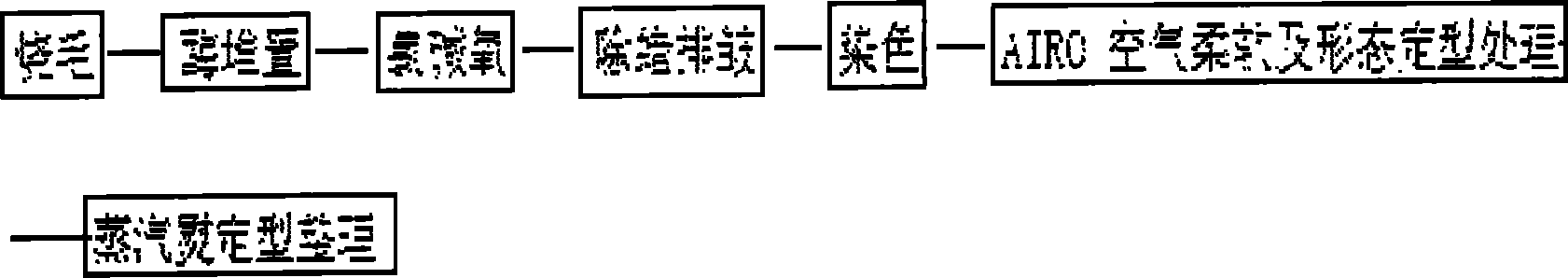

[0047] Process flow: singeing—enzyme stacking—chlor-alkali oxygen—wax removal and wrinkle removal—dyeing—AIRO air softening and shape setting treatment—steam ironing.

[0048] Specific process steps:

[0049] 1. singeing

[0050] Because pure flax fiber has more hairiness, in order to make the surface of the finished fabric smooth and uniform in color, it must be singed. Moreover, 2 / 2 reinforced singeing should be applied, and steel brush rollers should be used to brush the hairiness to ensure the quality of singeing;

[0051] Technological process: turning cloth → sewing head → cloth feeding → brushing → 2 / 2 singeing → fire extinguishing → cooling → cloth falling;

[0052] Process conditions: crater: 2 positive and 2 reverse, vehicle speed: 80M / min, steam extinguishing, crater temperature: 900℃~1100℃;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com