Polymer composite heat resisting waterproof sheet and preparation method thereof

A waterproof sheet and polymer technology, applied in chemical instruments and methods, layered products, other chemical processes, etc., can solve the problem of low heat resistance, self-adhesive waterproof membrane fracture tensile strength, transverse fracture elongation and tear Unsatisfactory cracking strength, wrinkling and other problems, to achieve the effect of improving physical performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

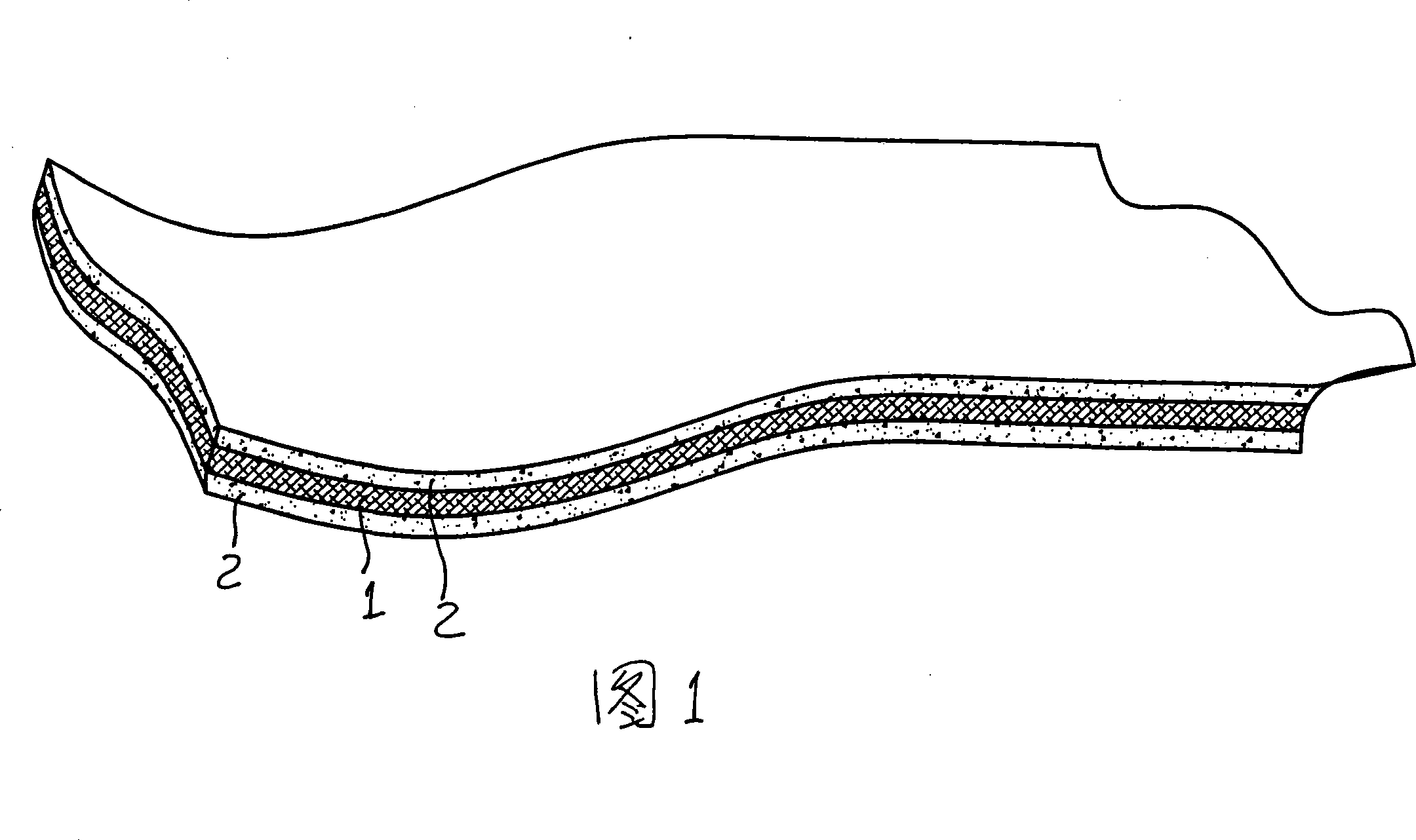

Image

Examples

Embodiment 1

[0036] First prepare the heat-resistant bonding aid:

[0037] The first step is to prepare materials

[0038] Accurately weigh 25 parts by weight of modified asphalt, 60 parts by weight of polyethylene, 10 parts by weight of silicate and 13 parts by weight of ethylene vinyl acetate;

[0039] In the second step, put the polyethylene, magnesium silicate, and ethylene vinyl acetate into a high-speed mixer at 90°C and stir for 15 minutes;

[0040] The third step is to put the modified asphalt into the mixer and continue to stir for 15 minutes;

[0041] Step 4: Add 3 parts by weight of silane coupling agent to the above-mentioned mixer, stir for 11 minutes, then open the discharge valve of the high-speed mixer to discharge the material to form a heat-resistant adhesive auxiliary agent and granulate it for later use.

[0042] The process of polymer composite heat-resistant waterproof sheet is as follows:

[0043] first step mixing

[0044] Take 50 parts by weight of linear polye...

Embodiment 2

[0060] The preparation process of thermal bonding additives is:

[0061] The first step is to prepare materials

[0062] Accurately weigh 20 parts by weight of modified asphalt, 70 parts by weight of polyethylene, 12 parts by weight of aluminum silicate and 15 parts by weight of ethylene vinyl acetate;

[0063] The second step is to put the above-mentioned polyethylene, silicate, and ethylene vinyl acetate into a high-speed mixer at 80°C and stir for 20 minutes;

[0064] The third step is to put the modified asphalt into the mixer and continue to stir for 20 minutes;

[0065] Step 4: Add 8 parts by weight of silane coupling agent to the mixer, and stir for 10 minutes to open the discharge valve of the high-speed mixer to discharge and granulate for later use.

[0066] The process of polymer composite heat-resistant waterproof sheet is as follows:

[0067] first step mixing

[0068] Take 50 parts by weight of linear polyethylene, 20 parts by weight of high-density polyethyl...

Embodiment 3

[0077] The preparation process of thermal bonding additives is:

[0078] The first step is to prepare materials

[0079] Accurately weigh 15 parts by weight of modified asphalt, 50 parts by weight of polyethylene, 8 parts by weight of calcium silicate and 15 parts by weight of ethylene vinyl acetate;

[0080] The second step is to put the above-mentioned polyethylene, silicate, and ethylene vinyl acetate into a high-speed mixer at 100°C and stir for 10 minutes;

[0081] The third step is to put the modified asphalt into the mixer and continue to stir for 20 minutes;

[0082] Step 4: Add 15 parts by weight of silane coupling agent into the mixer, and stir for 10 minutes to open the discharge valve of the high-speed mixer to discharge and granulate for later use.

[0083] The process of polymer composite heat-resistant waterproof sheet is as follows:

[0084] first step mixing

[0085] Take 80 parts by weight of linear polyethylene, 40 parts by weight of high-density polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com