Wood-wool, fibre board and method for making same

A wood wool board and wood wool technology, which is applied to flat products, manufacturing tools, and other household appliances, can solve the problems of insufficient rigidity of wood wool, twisting, and poor strength of wood wool boards, so as to overcome the defects of weather resistance and reduce cost, the effect of overcoming deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material for making wood wool is obtained from birch veneer chips after rotary cutting and rounding or slicing and square processing. The size of birch veneer scraps is: thickness 0.2-3mm; width 20-300mm; length more than 100mm; moisture content: 5-30%.

[0040]The veneer scraps can also choose poplar veneer scraps, willow veneer scraps, pine veneer scraps, and various post-veneer scraps produced by wood-based veneer processing enterprises.

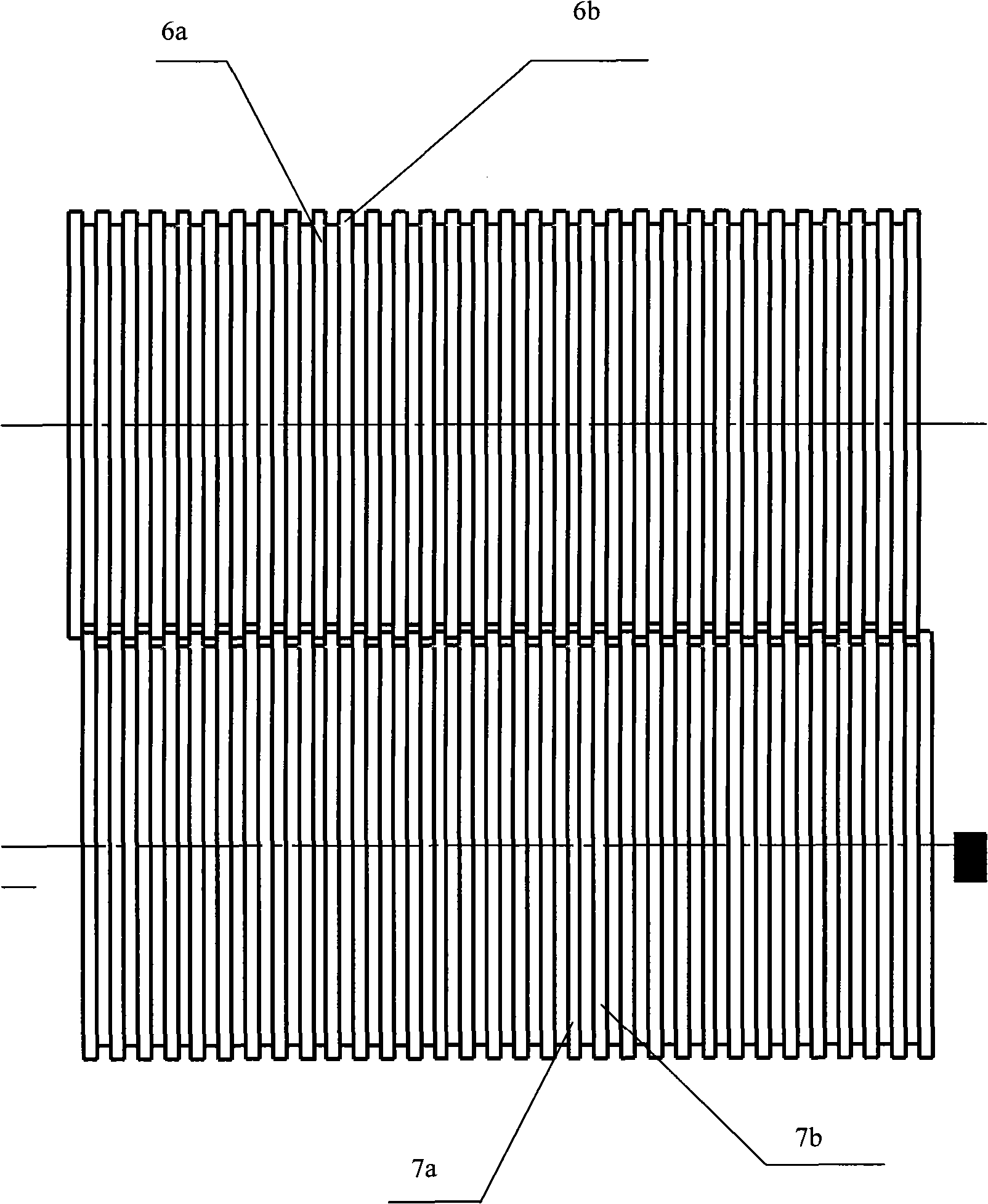

[0041] The technical process for preparing the wood wool fiber of the present invention will be described in detail below with reference to the accompanying drawings.

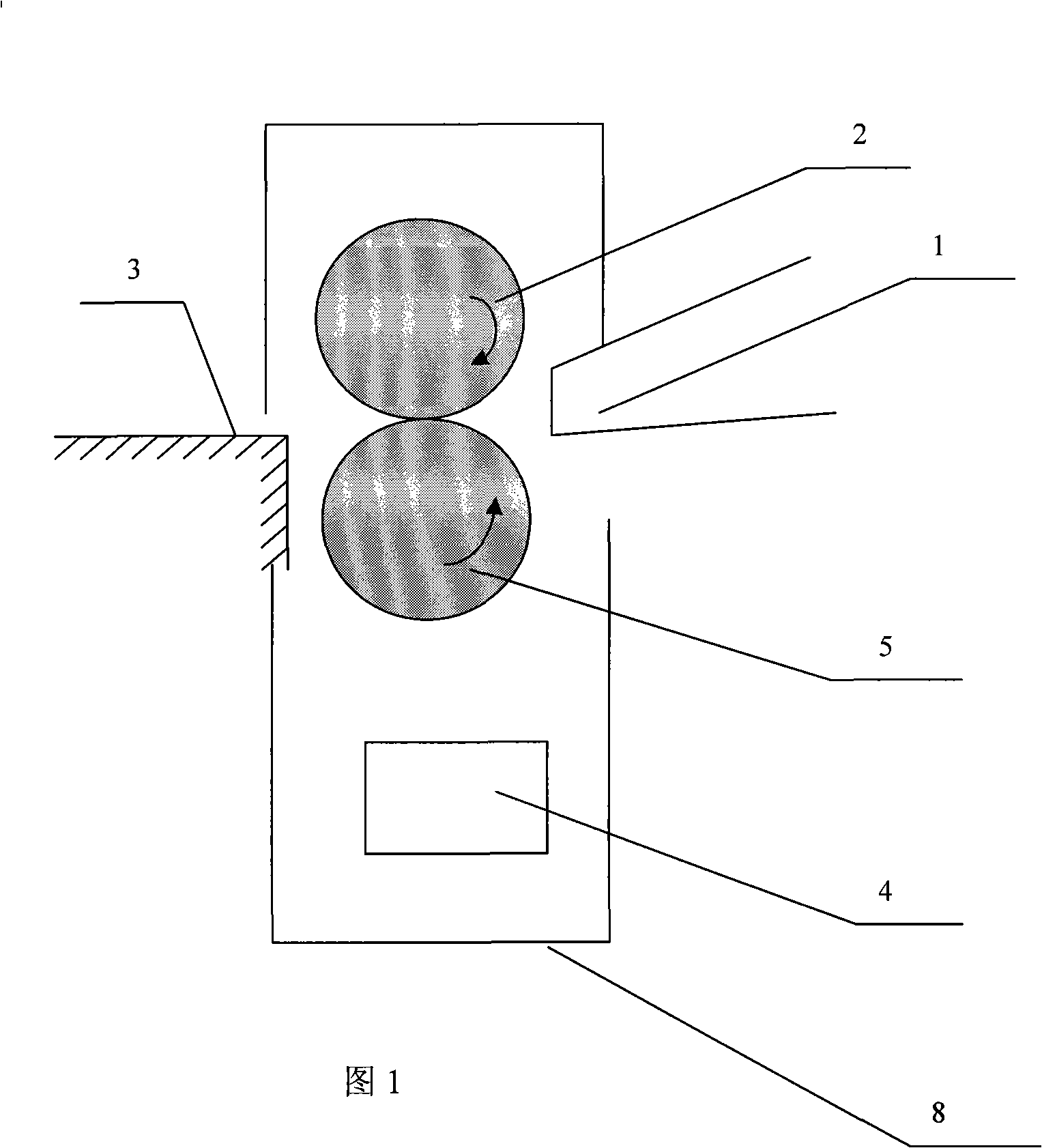

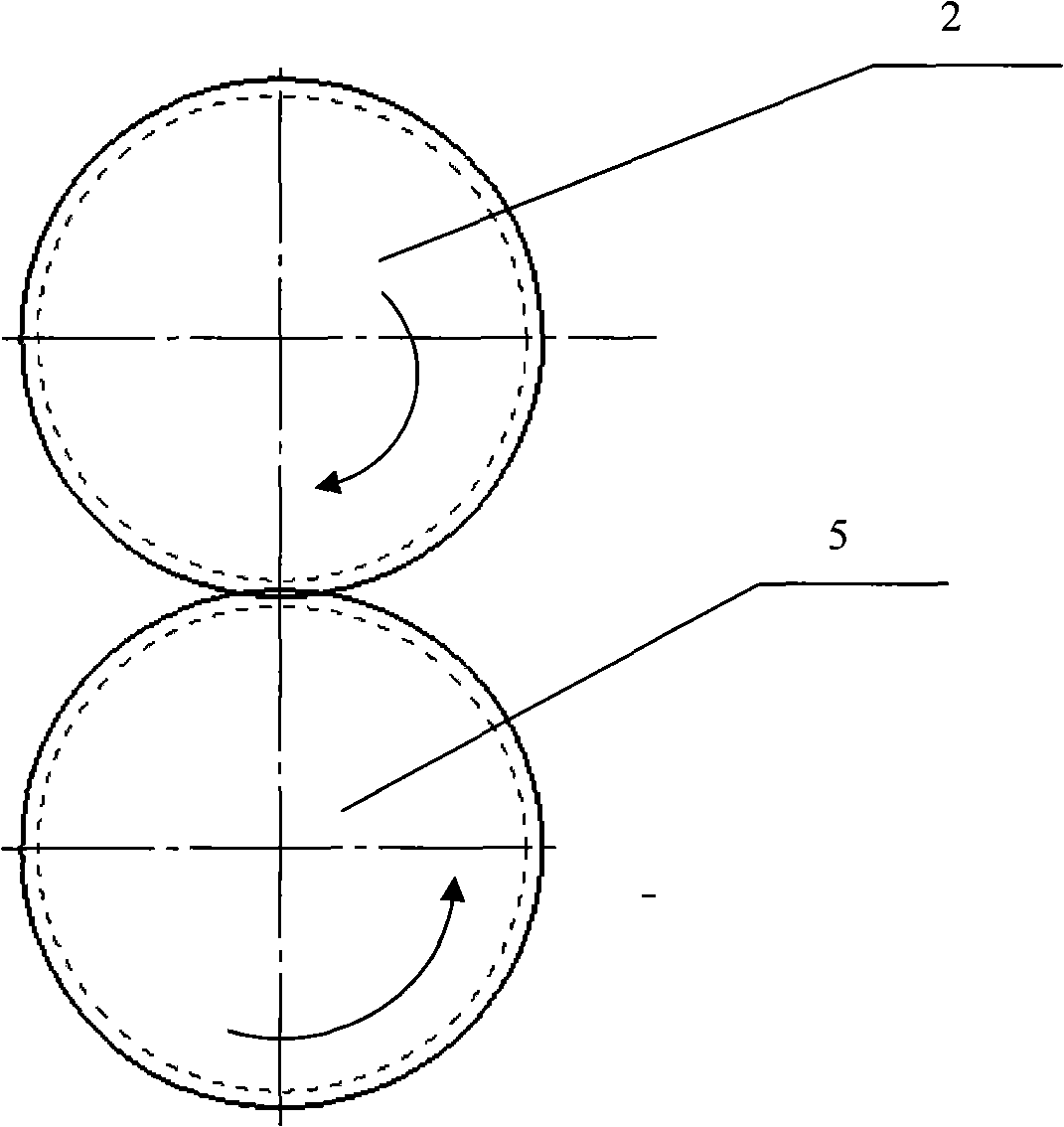

[0042] As shown in Figure 1, the wood wool production equipment includes a casing 8, a feeding device 1, a discharging device 3, a motor 4, and an upper combing roller 2 driven by the motor 4, a lower combing roller 5, and an upper combing roller 2. , The lower combing roller 5 and the motor 4 are arranged in the casing 8.

[0043] Among them, the paired c...

Embodiment 2

[0076] The axial width of the annular roller knife on the combing roller is 5mm, and the width of the birch wood silk fiber prepared after combing is 5mm. Other than that, it is the same as the first embodiment.

[0077] The process for preparing wood wool boards using the wood wool fibers of the present invention is described below.

[0078] 1) Pavement of wood wool fiber and first pre-pressing

[0079] The birch silk fiber strips are evenly paved along the fiber direction, and then the thickness of the paving slab is kept constant, and pressure is applied laterally from the width direction to perform limit preloading in the thickness direction.

[0080] Control the pre-compression pressure to 0.4MPa, the temperature to 35°C, and the time to 30s / mm (thickness of finished board).

[0081] 2) Slab sizing

[0082] The urea-formaldehyde resin glue with a solid content of 52% is diluted 40 times, and then the slab after the first pre-pressing is immersed in the glue tank, and t...

Embodiment 3

[0097] The axial width of the annular roller knife on the combing roller is 1mm, and the width of the birch wood silk fiber prepared after combing is 1mm. Other than that, it is the same as the first embodiment.

[0098] The process for preparing wood wool boards using the wood wool fibers of the present invention is described below.

[0099] 1) Wood wool fiber paving and first pre-pressing

[0100] The birch silk fiber strips are evenly paved along the fiber direction, and then the thickness of the paving slab is kept constant, and pressure is applied laterally from the width direction to perform limit preloading in the thickness direction.

[0101] Control the pre-compression pressure to 0.6MPa, the temperature to 35°C, and the time to 10s / mm (thickness of the formed plate).

[0102] 2) Slab sizing

[0103] The urea-formaldehyde resin glue with a solid content of 52% is diluted 30 times, and then the slab after the first pre-pressing is immersed in the glue tank, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial height | aaaaa | aaaaa |

| Axial width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com