Rare earth-titanium-nickel-containing sea climate resisting paint used for anti-corrosive treatment

A marine climate, anti-corrosion treatment technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of environmental and human hazards, coating containing hexavalent chromium, high curing temperature, to achieve environmental friendliness, excellent corrosion resistance, process temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides a water-soluble aluminum-zinc-silicon coating for anticorrosion treatment of marine weather-resistant engineering parts, wherein the coating comprises aluminum-zinc-silicon alloy powder, an organic solvent, a nano-oxide particle reinforcing agent, deionized water, a binder, Corrosion inhibitor, dispersant and thickener.

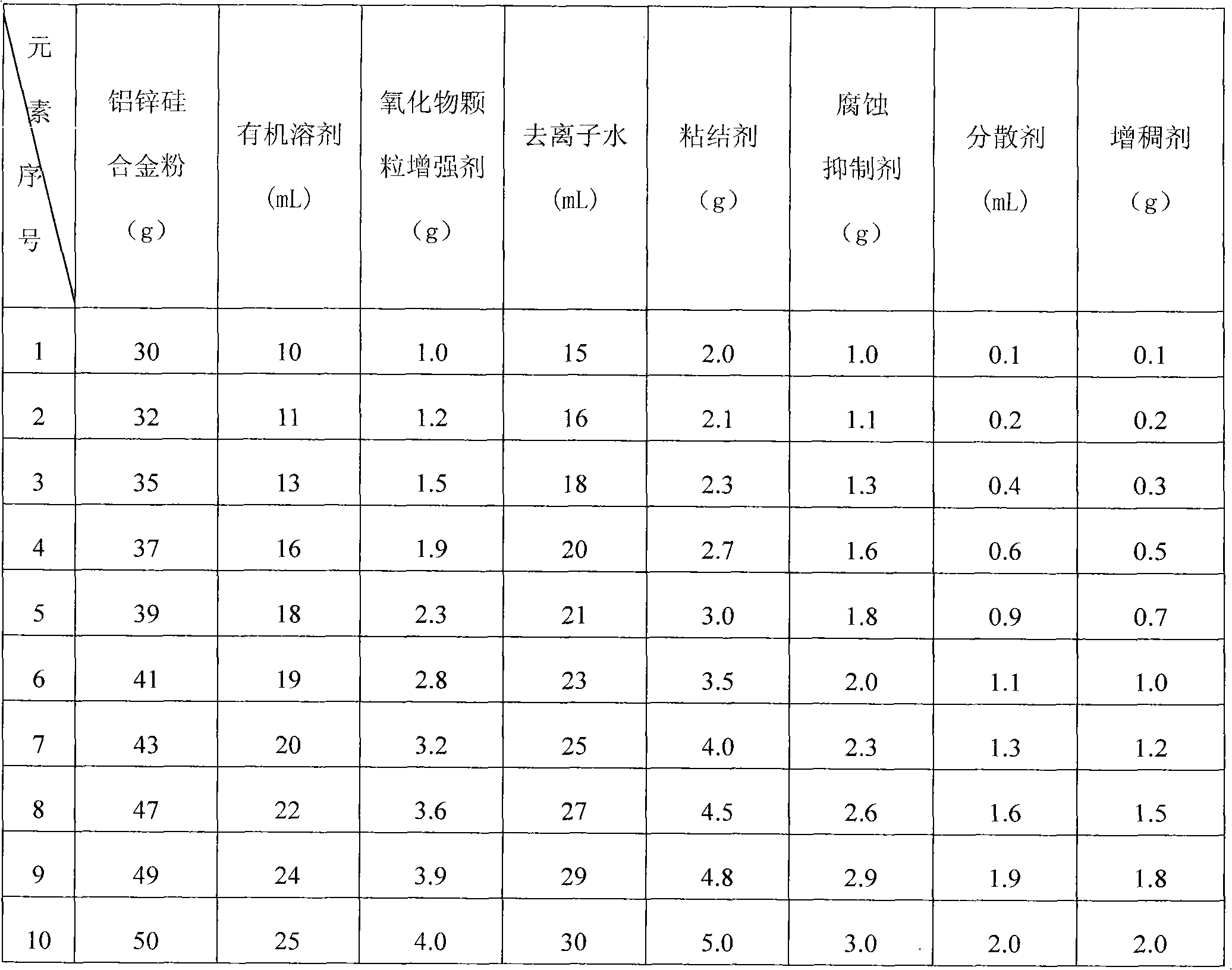

[0025] Below, some preferred embodiments of the coating formulation proportioning of the present invention are given in conjunction with Table 1, but the content of each component of the present invention is not limited to the numerical value listed in this table, for those skilled in the art, completely Reasonable generalizations and inferences can be made on the basis of the numerical ranges listed in the tables.

[0026] Table 1 Coating formula ratio

[0027]

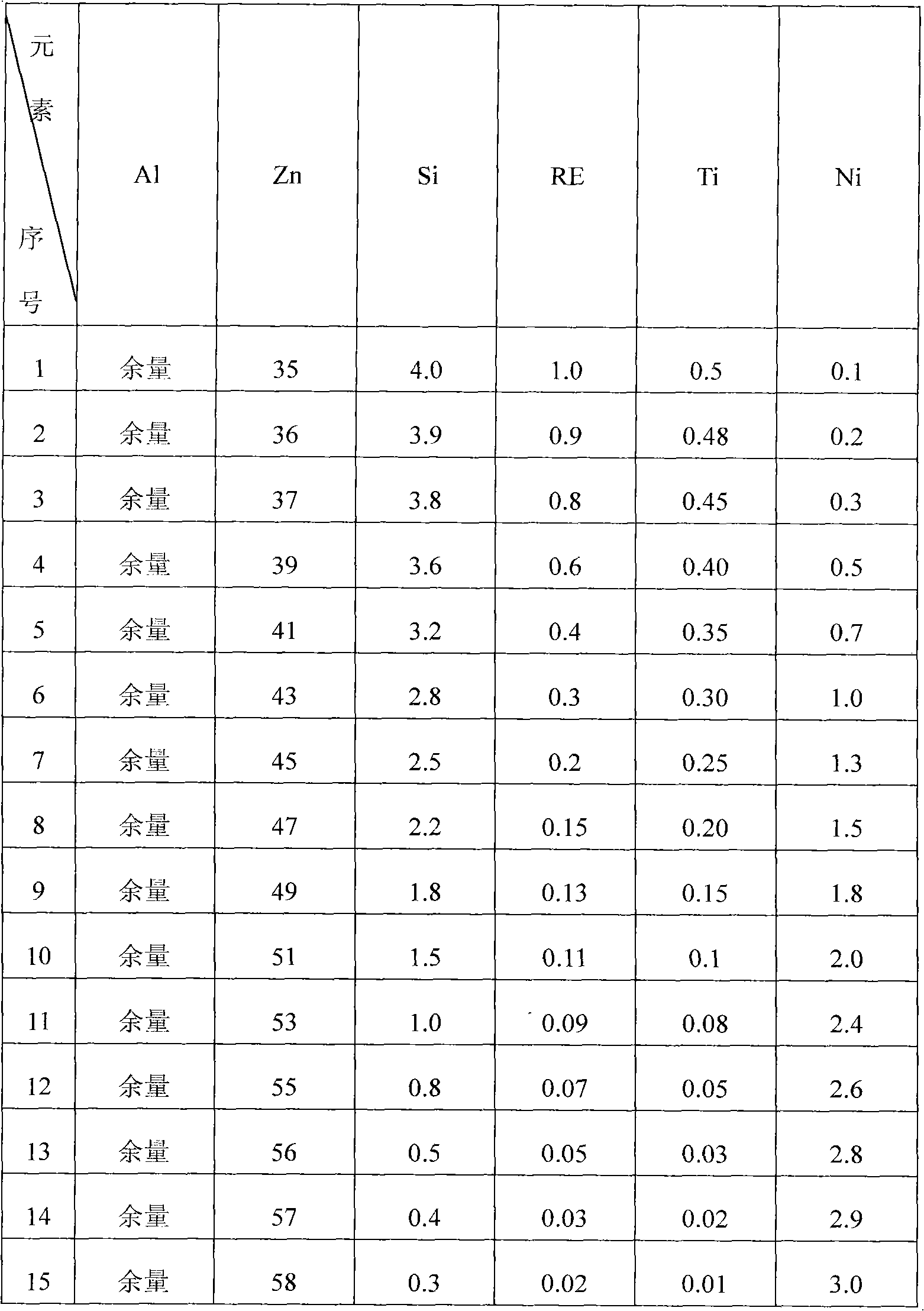

[0028] Wherein, the aluminum-zinc-silicon alloy powder is composed of Al, Zn, Si, RE, Ti, Ni. Below, some preferred embodiments of the mass percentages of the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com