Molding tool with a three dimensional surface relief pattern and method of making the same

A technology of surface relief and three-dimensional surface, which is applied in the field of molds with three-dimensional surface relief patterns and their production, and can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

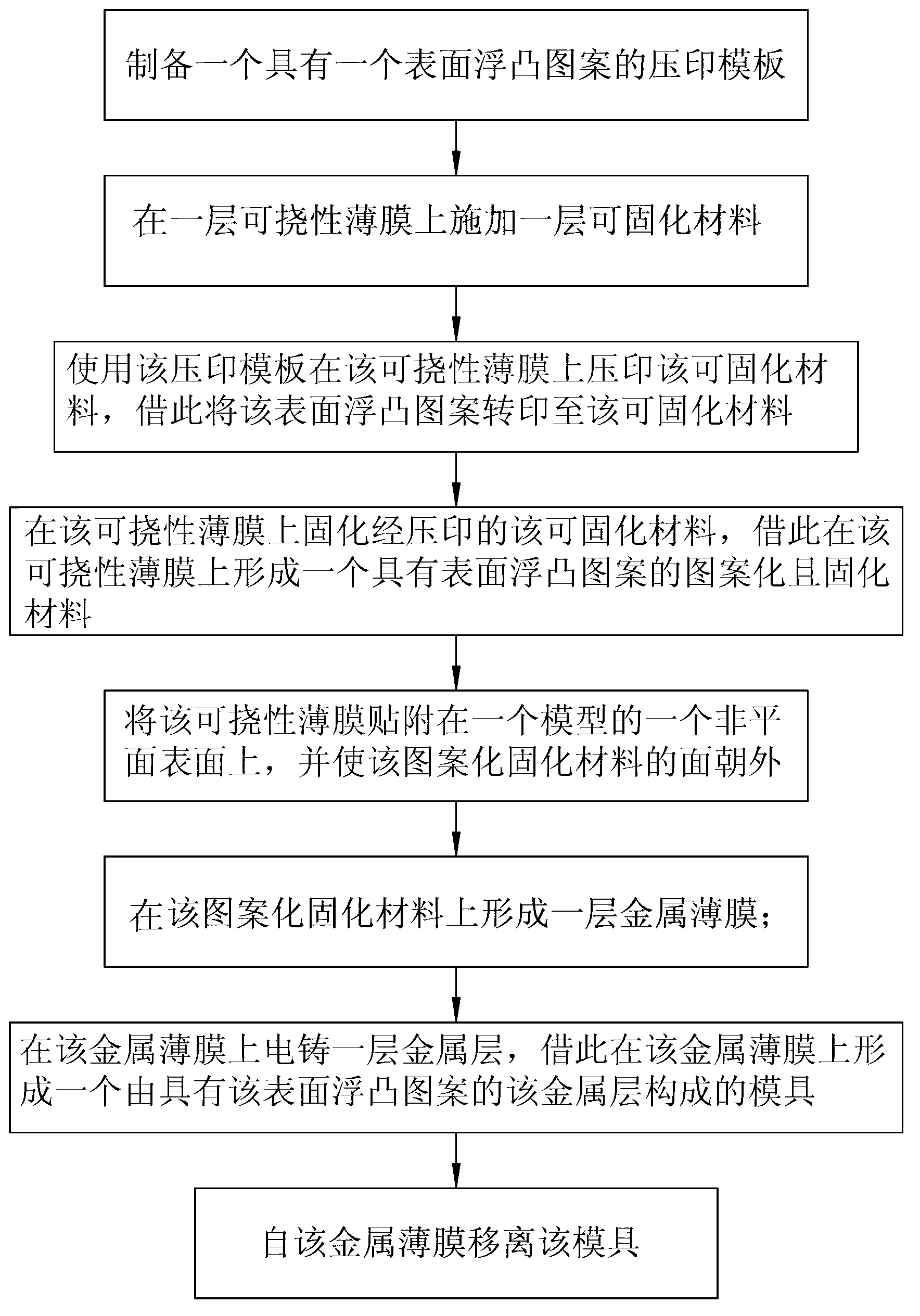

[0015] figure 1 and Figures 2A to 2K Means making a light-diffractive surface relief pattern with a three-dimensional surface relief pattern, such as a holographic pattern, or a pattern with a plurality of microstructures, each microstructure defined herein as having a micron size or nanometer The successive steps of the first preferred embodiment of the method of mold 29 are used for the production of a three-dimensional molded article (not shown), such as a mobile phone case having the three-dimensional embossed surface pattern.

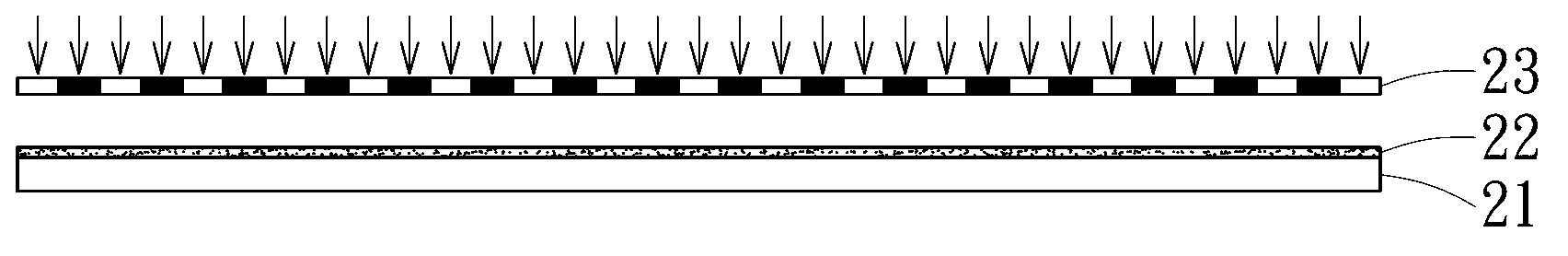

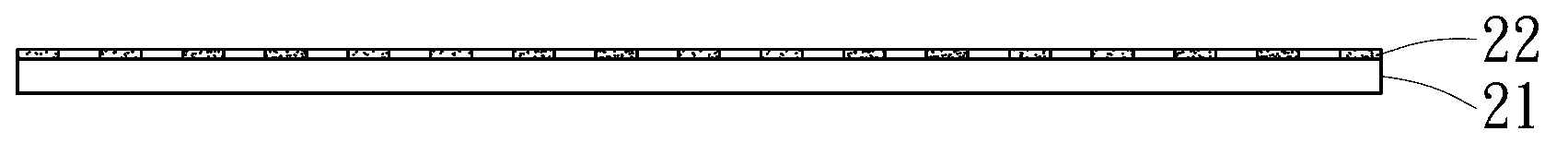

[0016] The method of the first preferred embodiment comprises: forming a photoresist material 22 on a substrate 21 made of a metal plate (see Figure 2A ); use a photomask 23 and form a surface relief pattern (see Figures 2A to 2B ); electroforming a metal layer on the patterned photoresist material 22, thereby forming an imprint template 24 with the surface relief pattern on the patterned photoresist material 22 (see Figure 2C ); remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com