High strength waterproof stone-wood floor and technique for producing the same

A stone and wood flooring and production process technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of non-waterproof and moisture-proof, large deformation, easy to slip, etc., to achieve high waterproof, low cost, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation materials for the high-strength waterproof stone-wood floor include the following raw materials and parts by weight:

[0025] 58 parts of stone powder, 20 parts of polyvinyl chloride resin, 3 parts of stearic acid, 2 parts of lead stearate, 3 parts of barium stearate, 5 parts of chlorinated polyethylene, and 5 parts of dibutyl ester , Paraffin is 4 parts.

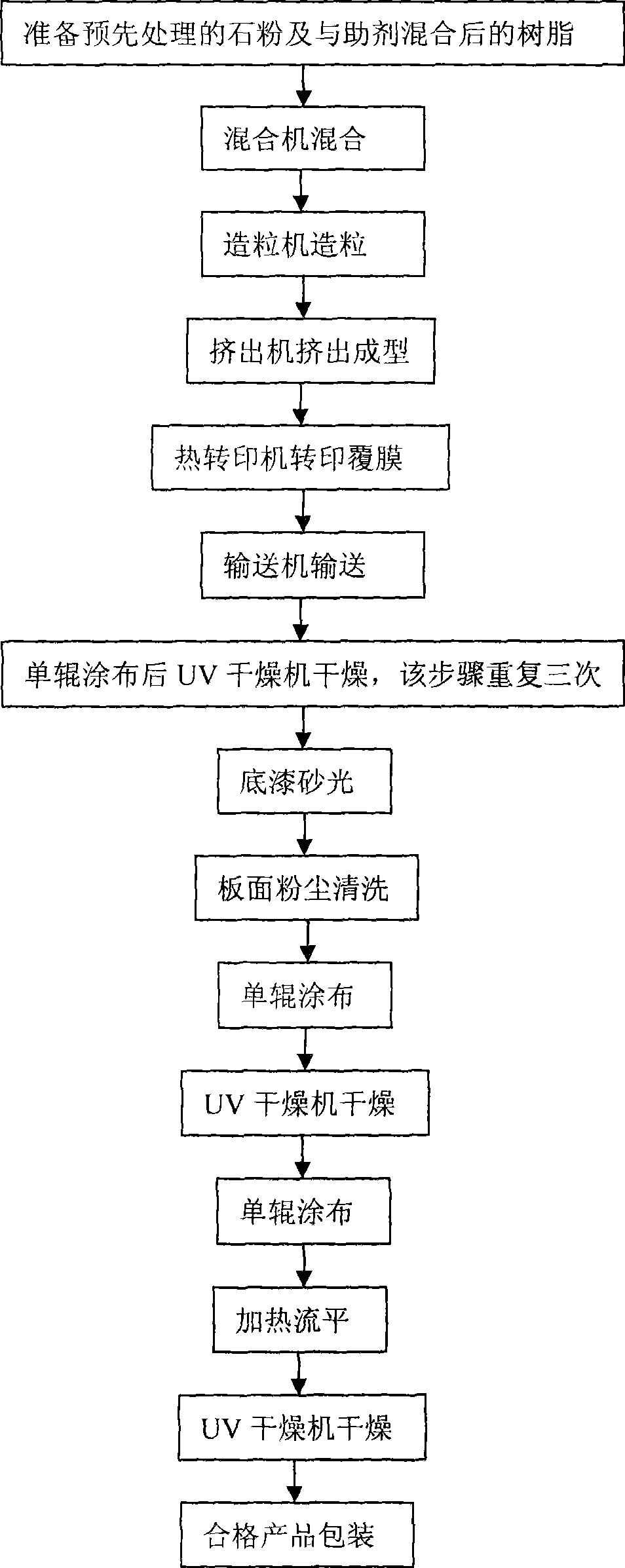

[0026] The production process of the high-strength waterproof stone-wood floor is as follows: figure 1 As shown, the details are as follows:

[0027] 1. Granulation

[0028] 1. According to the above formula, weigh the mixture comprising the following raw materials in parts by weight: 58 parts of stone powder, 20 parts of polyvinyl chloride resin, 3 parts of stearic acid, 2 parts of lead stearate, and 3 parts of barium stearate. 5 parts of chlorinated polyethylene, 5 parts of dibutyl ester, and 4 parts of paraffin. Put the mixture into a high-speed mixer, set the temperature of the mixer to 80°C, s...

Embodiment 2

[0043] The preparation materials for the high-strength waterproof stone-wood floor include the following raw materials and parts by weight:

[0044] Stone powder is 52 parts, polyvinyl chloride resin is 30 parts, stearic acid is 2 parts, lead stearate is 2 parts, barium stearate is 5 parts, chlorinated polyethylene (CPE) is 3 parts, dibutyl ester 3 parts for paraffin and 3 parts for paraffin.

[0045] The production process of the high-strength waterproof stone-wood floor of Embodiment 2 is the same as that of Embodiment 1, except that the mixture of Embodiment 2 in the batching process includes the following raw materials and parts by weight: 52 parts of stone powder, 30 parts of polyvinyl chloride resin, 30 parts of stearin 2 parts of acid, 2 parts of lead stearate, 5 parts of barium stearate, 3 parts of chlorinated polyethylene, 3 parts of dibutyl ester, and 3 parts of paraffin.

[0046] The high-strength waterproof stone-wood floor of the present invention has a unique fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com